- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drop-forging

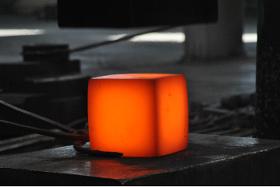

Results for

Drop-forging - Import export

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

KB Schmiedetechnik GmbH is a drop forge in West Germany, located between the historic “blade & metal region” Solingen-Remscheid-Wuppertal and the “Borussia soccer city” Dortmund, specialized in small series production of safety-relevant closed die forgings from 200g to 130Kg unit weight of all steel grades and alloys according to following certifications and standards: pressure equipment: valves, boiler systems, piping PED 97/23/EG, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering, certified by •American Bureau of Shipping (ABS) •Bureau Veritas (BV) •Det Norske Veritas (DNV) •Lloyds Register (LR) •Nippon KaijiKyōkai (ClassNK) Examples: components and equipment like brackets, holders, chain links, hoists, lifting hooks, fasteners, pressure-bearing parts like valve bodies, pipe connections, and more.

Request for a quote

FORJA NEPTUN SRL

Romania

FORJA NEPTUN has the capability to produce forged parts from carbon steel, alloy steel and high alloy steel, as well as rough or final machining on forged blanks/ parts.

Request for a quote

SIMA DIS TICARET ALUMINYUM SAN. A.S.

Turkey

we have capability to forge different kinds of aluminium including 7075-2014-7049-6061-6063 etc. please feel free to get in touch with us

Request for a quote

MAROVT D.O.O.

Slovenia

Precision forged parts are forged parts where very narrow tolerance can be achieved by following the forging process permanently. Our processes enable forging with the +/- 0.1mm tolerance. We are specialized in the production of precision forged parts weighing between 0.001kg and 1kg made of different material. The advantage of precision forged parts is that they can be used mostly in different compounds and without additional mechanical machining. Hot die drop forging is the method in our company – sticks are heated and inserted into the appropriate forging tool.After the forging process, we trim and pierce the semi-finished products to meet many shapes and other requirements. We shape stainless, alloy and carbon steels. In most cases, more complex and larger forgings are further machined.Due to the specificity of precision forgings, we provide the minimum necessary additional machining and thus reduce the machining times.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication for thermoforming processes, e.g. drop-forging, hot extrusion, hot rolling or hot bending of steel and non-ferrous metals Thin-film lubrication of sliding surfaces of all kinds on production machines, e.g. column guides of forging presses Advantages and benefits Excellently suited for improving workpiece surfaces and increasing tool service life Highly effective due to optimum solid lubricants with good separating effect Broad range of uses for various thermoforming processes Low consumption due to thin-film lubrication Marked separating and lubricating functions in all temperature phases Free of graphite, which can lead to carburising of tool and workpiece For best adhesion, clean contamination and other lubricants from slide surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaning agent. Use a brush, spatula or similar to apply evenly a suitable quantity of paste onto surface. The paste will also act as a sealant.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FILLTECH GMBH

Germany

Our experience in filling cylinders has enabled us to develop our own pump technology which has proved its worth in a number of fields in addition to filling cylinders. Pump aggregate NP 10/15 Performance Min./Max.: 150-300 kg/h 0.6-1.2 gal/min Power cons.: 1,5 kW Motor: 3x400 V, 50/60 Hz Drive: V-Belt Dimensions (LxWxH): 600x400x500mm Weight: 40 kg Pump aggregate NP 25/50 Performance Min./Max.: 400-1000 kg/h Power cons.: 3,0 kW Motor: 3x400 V, 50/60 Hz Drive: V-Belt Dimensions (LxWxH): 800x600x500mm Weight: 85 kg Pump aggregate NP 25/70 Performance Min./Max.: 600-1500 kg/h Power cons.: 4,0 KW Motor: 3x400 V, 50/60 Hz Drive: V-Belt Dimensions (LxWxH):800x600x500mm Weight: 85 kg The following stats are valid for all pumps: Materials Valve casing: Special brass / cast bronze Valves: High grade stainless steel Plunger: Ceramic Sleeves: CO 2/N 2O – resistant compound; fabric reinforced Support rings: Teflon with graphite, run-dry-proof Crankshaft: Drop-forged and case hardened Pump

Request for a quote

FORJA NEPTUN SRL

Romania

Diameter (D,d): ø50 ÷ ø650 mm Length (L,l): 500 ÷ 6000 mm Weight: 50 ÷ 5000 kg

Request for a quote

EGE FORGE

Turkey

Closed Die Forging Range of 0,5 to 8kg gross weight

Request for a quoteResults for

Drop-forging - Import exportNumber of results

9 ProductsCountries

Company type