- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forging metals

Results for

Forging metals - Import export

FATIH WROUGHT IRON

Turkey

Weight: 7,93 kg Height: 1 cm Width: 4 cm Material: 3 m

Request for a quote

FORJA NEPTUN SRL

Romania

Diameter (D): 100 ÷ 1000 mm Diameter (d): 50 ÷ 700 mm Weight: 10 ÷ 4000 kg

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Below are a few reference objects that we have been able to work on as part of a wide variety of project tasks in recent years: Audi: all RS models since 2000, R8, R8 2015 Bentley: Mulsanne, Bentayga BMW/Mini: Clubman, 3 series Ferrari: 599 GTO Lamborghini: Gallardo, Murcielago, Aventador Mercedes: S-Class, SLS, Actros Porsche: 997, 911 I panel, door trim, center console, greenhouse, interior trim, trim, steering wheel, seats, carpet trim, infotainment system, instrument cluster, mirror, selector lever, switch panel, trunk, engine compartment cover. Wheels, brakes, wheel suspension, exhaust system, engine components, tank, lines. Plastic injection moulding, metal casting, forging, forming, tube processing, painting, galvanic surfaces, lamination, leather covering, upholstery and sewing.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Precision stamping is very fast and cost-effective manufacturing solution for large quantity with high tight tolerance in assembly and application, the precision we can achieve is 0.001mm on our press machine and stability of dies. Metal stamping uses high tonnage presses and stamping dies to forge sheets of metal into complete or semi-complete parts. Precision metal stamping improves the speed and accuracy of complex stamping applications by allowing the stamping, folding, drawing, or piercing of a product in a single or series operations.

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Graphite-free lubricant for the forging of aluminium Temperature Range 130 °C to 380 °C Properties and Advantages • improved cleanliness of work environment (graphite-free) • reduced wear on tool surface due to the forming of an effective release film • good release of forgings • formation of a pressure resistant lubricating film • forgings can be painted and powder coated, downstream processes are trouble-free • alternative to graphite containing products

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Forging lubricant for aluminium and non-ferrous metal Temperature Range 160 °C to 400 °C Properties and Advantages • promotes the metal flow during forming process resulting in optimal form filling and accurate, precise parts • perfect release • much cleaner forgings, hardly any residues • reduced cleaning effort • high surface quality • improvement of tool die life due to adhesion of protective graphites • various modifications available e. g. Graphitex® CR 25-9/14

Request for a quote

EXTRA FORGE D.O.O.

Slovenia

Our expertise lies in the meticulous development of tooling for both steel and aluminum forgings, ensuring that the need for post-processing of the pieces is minimized. By perfecting the tooling process, we strive to deliver forgings of exceptional quality with minimal additional work required. Moreover, we offer valuable recommendations to our clients regarding potential alterations to the forging piece aimed at reducing costs without compromising on quality. Our goal is to optimize both the piece and the die to enhance efficiency and cost-effectiveness.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd.is professional ISO9001 certificated Metal Parts Parts manufacturer, Located in China Ningbo,Specialize in Services of Sheet Metal Stamping,CNC Turning & Machining,Tube Bending, Cold forging & Hot Forging, and also can provide outsourcing services of laser cutting & Casting. We produce metal parts for various indstries,custom produce a wide variety of machine parts and hardware components according customer’s drawing or sample,such as kinds of machined parts – metal shafts,steel rods, bushings, Sleeves, Flanges, tubes; Metal stamping brackets, frames, clamps, casing, housing; deep drawn components; tube bending components; cold forging parts,studs,bolts,screws,nuts,pins; steel wire forms and all kinds metal components. We provide a wide range of machining services, can satisfy the customer many types of products one-time order, for the customer to save a lot of trouble and costs for buy in different suppliers.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg as a professional metal parts supplier, specialize in Hot forging services, we can produce small hot forged parts by ourself and outsource the big hot forged parts as blanks then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. Forging refers to the process of forging and pressing metal objects in a red hot state with air hammers or presses (die stamping machine). Forging is to bake and knead the metal of the object into a shape. Nowdways, we use a high-frequency heater to heat the metal object to a red state within a few seconds, and then put it into the mold cavity for compression molding. We can produce forged parts from stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Brass Forging Parts is a metal alloy that consists primarily of copper and zinc. The mechanical properties of brass depend on percentage of zinc along with several additional elements, which can vary significantly. Brass is harder and has a lower melting point than copper, but it has excellent working properties and is excellent for many end usesOrdering brass bar stock to the specified alloy composition in one of the many forms and shapes available is the typical first step in the process. Saw cutting provides blanks, sometimes called slugs, that then enter the forging or forming process. Some grades of brass alloy may be processed at room temperature, but it is most common for slugs to be heated to improve formability. Temperature for hot forging is usually in excess of 1000 degrees F but both the alloy and complexity of the configuration will determine the exact process requirements. In the forging process, the cut slugs are placed between dies and force

Request for a quote

PJM MECHANICAL CO.,LTD

China

Hardware processing is also called metalworking. It includes metal forming processing and metal surface processing. Metal forming processing includes stamping and forging. The metal surface processing includes plating, surface polishing, and frosting. Mechanical components are also one of the widely used products. They are an important part of various motion control and transmission machines.

Request for a quote

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

Within the Rt Makina Production Facility; With over 10 high-tech CNC benches, it can process complex and sensitive parts that will be manufactured from aluminum, zamak, steel, stainless steel, titanium, magnesium/nickel-based materials in the form of plate, sheet metal, casting and forging in accordance with customer specifications.Machining is a manufacturing method that covers the shaping of the pre-designed and constructed machine element, the manufacturing process of which is determined, by subjecting it to the cutting operation with the specified cutting tools on the machining benches suitable for the manufacturing process.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Temperature range: 250 °C to 3200 °C 4-year warranty Durable IP65 (NEMA4) housing Manual Variable focus Sighting options: Laser through the lens and Visible through the lens Video Camera through the lens and Visible through the lens LED through the lens and Visible through the lens LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring and field calibration Single or two color models available APPLICATIONS Metals processing: molten metal/forging, hot rolling mills, rod/wire mills Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Broad temperature range 50 to 3200°C 4-year warranty Durable IP65 (NEMA4) housing Visible through the lens sighting and manual variable focus plus optional laser sighting, video camera, or LED sighting LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring, and field calibration In addition to single-color models, the series also comprises two-color (ratio) pyrometers and models with a remote sensor head (Endurance Glass-Fiber). APPLICATIONS Metals: forging, hot rolling, rod/wire production Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quote

FRANCKE-ART

Poland

We manufacture hand forged ornamental metal gates and fences as per client’s requirements. We specialise in the production of intricate palace-like grand gates with decorative forged elements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

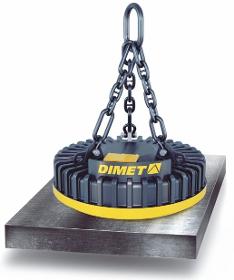

DIMET GMBH

Germany

Transported cargo: Slabs / Forgings / Heavy-weight metal blanks. Compatible equipment: Cranes / Spreader beams. Energy saving as per ton of the transported cargo / Heat-resistant version (cargo temperature up to 650°C) / Aluminium coil

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

ACCUTOOL LTD.

Ireland

Areas of specialisation include:Sub assembly Electro mechanical assembly - machined - cast forged - stamped - extruded metal - plastic parts Industry components - electronic - energy - liquid gas - industrial valve - water supply - communications After we have manufactured many of your subcomponents, take advantage of our mechanical assembly cell to integrate assemblies or subassemblies ready for your final production line. ** Ask for a quote **

Request for a quote

TOHOKU BOLT MFG. CO., LTD.

Japan

Forging high quality bolts for Wind Power Generation Tower made in Japan have been approved by Japanese METI certificate.

Request for a quoteResults for

Forging metals - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Forming - steels and metals (2)

- Gears (2)

- SMALL METAL PARTS (2)

- Steels and metals - forming and cutting (2)

- Thermometers (2)

- Steel, crude (1)

- Cements, special (1)

- Forges - machinery and installations (1)

- Heat treatment of steels and metals (1)

- Lifting equipment (1)

- Machine tools - metal machining (1)

- Precision mechanics (1)

- Shaping - steels and metals (1)

- Steel & Metal Transformation (1)

- Steels and metals - machining (1)

- Thimbles, forged (1)

- Vehicles - mechanical components and parts (1)