- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high pressure homogenizers

Results for

High pressure homogenizers - Import export

WHITE STEEL GMBH

Germany

Permanently mixing Substances in a liquid Capacity from 16 to 16000 gph Compact design It is A3 certified and is electrically pre=disposed for ULCSA Pre-tested for quality control and stress test Manual Electric control panel 3 steps treatment for more product stability during subsequent treatments and storage Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The DaiTec offers all the advantages of the Conti-TDS technology and is specially tailored to the requirements of the milk processing and food industry. It is characterized by its 3A certified design and a powder feeding table with integrated hopper at an ergonomic working height. It is connected directly to existing containers and is ready for operation after a few simple steps. Due to its powerful suction vacuum, the machine can suck in and disperse directly from the powder container by means of a suction pipe in addition to suction from the hopper. It ensures dust-free container emptying, powder transport, powder introduction, powder wetting and dispersion. Agglomerate-free, highly concentrated, homogeneous and very stable dispersions due to the use of high shear energy and the wetting/dispersing of powders under vacuum. Excellent emulsifying properties - narrow spectrum of droplet size even without high pressure homogenizer. 3A-certified design

Request for a quote

KASAG SWISS AG

Switzerland

We are your experts in design, engineering, and manufacturing of welded versions of high-pressure apparatuses, high-pressure autoclaves and plants. With comprehensive non-destructive testing methods, such as X-rays of the welding seams or pressure testing of up to 1000 bar, we ensure smooth product quality. With KASAG products, you can withstand pressure.

Request for a quote

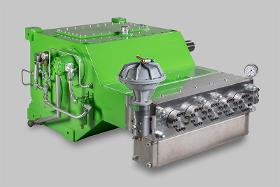

KAMAT GMBH & CO. KG

Germany

Performance in a small space Our compact K100-3 high-pressure three-plunger pump boasts impressive performance data: With only 15 kW of input power, it delivers a pressure of 2000 bar, making it one of the most powerful pumps in its size class. The K100-3 triplex plunger pump really comes into its own when it comes to water jetting for industrial high-pressure cleaning.

Request for a quote

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quote

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quote

KAMAT GMBH & CO. KG

Germany

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

Autofrettage is a method for increasing fatigue strength of components for use at high and pulsating pressures. In short, Autofrettage compresses a container’s inner surface, making better use of the material’s structural properties. The process can reduce fatigue concerns in pulsating applications and lets engineers reduce tubing thickness in high-pressure applications without sacrificing strength, life, or safety. The autofrettage method is based on the reciprocal relationship of the plasticized inner zone and the elastically deformed outer zone. The components are placed under so much pressure that their interiors become plastically deformed. After relaxing, pressure stresses are created in these areas, which prevent the outer areas from reforming to their original shape. Instead, it remains stretched. This prevents crack formation in the later application, increases the service life of

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Bend 90° F/F

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Reducer

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Coupling

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). End cap

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC).

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Reducing coupling

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Bend 45° F/F

Request for a quote

BÜCHI AG

Switzerland

Laboratory high pressure / high temperature reactor (HPHT) Standard Version: Reactor volume: 100 - 600 ml Pressure: -1 (FV) to +400 bar Temperature: -20 °C to + 400 °C Material: stainless steel, (Hastelloy® +400 °C) High-Pressure Version: Reactor volume: 100 - 600 ml Pressure: -1 (FV) to +500 bar Temperature: -20 °C to + 500 °C Material: stainless steel, (Hastelloy® +400 °C) This is our new high pressure and high temperature HPHT (high pressure high temperature) autoclave novoclave. This high pressure reactor system is designed for processes involving high pressures and temperatures. Safety features guarantee safe reactions under highest pressure. Designed, manufactured, and tested according to PED, AD2000. The modular setup of the novoclave system allows for changing the vessel size from 100 ml up to 600 ml using the same cover plate and electric heating block. Vessels are available in the following volumes: 100, 200, 300, 450, 600 ml.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Superior Tube supplies high pressure tubes that exceed current industry standards and we supply high quality products that are used in oil and gas extraction, high pressure liquid chromatography, military applications, water jet cutting, and more. Our tube mill manufactures high pressure tubing in straight lengths, and in a variety of corrosion resistant austenitic, nickel alloys, and stainless steels. Sizes run from 0.050” right up to 1.250” outside diameter, with wall thicknesses between 0.0175” and 0.218”. Operating conditions can require our products to be service rated above 60,000psi operating pressure, with tensile strengths greater than 220ksi. Please note that we have a minimum order value of £10,000.

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). SANHA RefHP Tee

Request for a quote

HIPRUN POMPA VE CNC EKIPMANLARI

Turkey

Double filtration system is used in our high pressure coolant sytems. They are easily removable and cleanable. On the other hand, especially the main feature of this system is not to be obligated to stop machine during cleaning and changing filter. One filter can be operated with machine while another is been cleaning. This will provide you the time saving during filter change Multiple Manifold Block with 4 outlets is provided as standart in this model. However, it can be manufactured over 4 outlets depending on your requirements at your machining process. HP2 High Pressure Coolant Units are used as mobile station. They have wheels under units and you may easily move it where you prefer them to be placed at your workshop.

Request for a quoteResults for

High pressure homogenizers - Import exportNumber of results

25 ProductsCompany type

Category

- Connectors, plumbing (10)

- Pumps (4)

- Gear pumps (2)

- Piston pumps (2)

- High-pressure cleaning machines (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Autoclaves (1)

- Finished Metal Products (1)

- Food industry - machinery and equipment (1)

- Milk (1)

- Steels, nickel (1)

- Testing equipment (1)