- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ink-jet printer

Results for

Ink-jet printer - Import export

MEDEK & SCHÖRNER GMBH

Austria

Special high speed adapted ink jet printer with finely adjustable printhead support for marking bandmarks from one side on the fiber at speeds up to 1150 m/min. The usual arrangement allows bandmarking in line with the ink coating process, providing irradiator units after the ink jet printhead and the ink applicator. In case that no additional UV lamp unit and only the UV lamp of the UV curing unit CCD1-K unit is available, bandmarking has to be done in a separate process (either bandmarking or ink coating). The microprogram of the ink jet printer is specially adapted for ultra high speed bandmarking with automatic control of a constant bandwidth over the full speed range. Bandmark pitch and interband distance for multiple bandmarks (double, triple, etc.) are easily programmable on the computer screen. LD - INK LEVEL SENSOR AND INDICATOR SYSTEM FOR INK TANKS Triggers a warning signal as the ink level drops below minimum.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

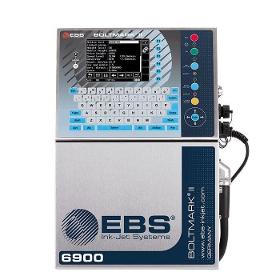

EBS INK JET SYSTEME GMBH

Germany

The new generation of BOLTMARK ® II printers has increased in terms of performance, functionality and reliability. Our engineers have created a product that will not let you down, even under the toughest conditions, and will also work highly efficiently. ACPS - Anti Clogging Power Supply: Worldwide innovation: for the first time in a Continuous Ink Jet Printer, a built-in automatic and intelligent system provides reliable printer operation in case of power failure. Should the power be interrupted for less than 30 seconds, the printer continues operating. If the supply is cut off for more than 30 seconds, the printer starts the automatic shutdown procedure including rinsing, to protect the tubes from dried ink deposits. As soon as the power is restored the printer is quickly operational again. The ACPS contains very long-lasting Super Charger Capacitors, not conventional accumulators. Charging lasts only around 2 minutes. The ACPS is available optionally only for EBS-6600 and EBS-6900.

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

The ink-jet printer EBS-230 of the "PicAS"-series sets new standards in regard to configuration and cost-effectiveness of basic DOD (Drop on Demand) systems, which remain relevant to newest DOD systems. With a print height of 6mm up to 27mm (depends on selected version) and a print speed up to 60m/min the EBS-230 is the perfect marking system for small to medium production volumes. The ability to use fast-drying inks on Ethanol-, Acetone- or MEK base provides a universal solution for various marking applications. No matter if the surface is made of cardboard, plastics, metal, glass or ceramics. Trough a process of consistent development of the established line coder "PicAS" EBS-200 we created a totally splash water protected system which is also independent from external compressed air.

Request for a quote

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

Measurement of the surface tension The adhesion of a surface is usually directly dependent on the surface energy. If the surface energy is substantially lower than that of the printing ink used, the wetting is disturbed, resulting in poor adhesion. For this reason, plastic surfaces have to be pre-treated. Depending on the type of ink used the surface tension required can vary: solvent based inks => 38 bis 42 mN/m (=Dyn/cm) water soluble inks => 40 bis 44 mN/m UV inks => 44 bis 46 mN/m With the test inks of AFS, which are available from 34 to 56 dyn/cm surface tensions of plastic films can be easily and reproducibly determined according to DIN ISO 8296. Depending on whether the ink sticks or bubbles on the surface it indicated whether the surface tension is above or below the dyne-value of the currently used test ink. We also offer the test inks in a case with 12 bottles from 34 to 56 dyn/cm.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

B - STROBOSCOPE Automatically synchronized flashing stroboscope for monitoring the quality of printed marks. High quality finish with tight and resistant to solvent metal casing. VST - VIDEO SYSTEM FOR MONITORING THE PRINT QUALITY Medek & Schörner also offers a video system for monitoring the print quality of fast-running cable printing machines, e.g. allowing real-time inspection for bad quality and/or missing prints. FM-P - REPLACEABLE INK SUPPLY MODULE With ink tank, pump, cooler, filters, and ink flow fine adjustment and selector valves. Allows the printing ink to be changed in about 2 minutes. Ink can be stored in the ink tank for several weeks with no degradation of ink properties.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

High-performance gravure printing machine with single printing station for marking hot cable insulation. Marking of text and numbers Print wheel drive up to and above 1200 m / min Ink supply system for use with original ink containers Single head STANDARD CONFIGURATION Frame with support column and height adjustment crank mechanism. Marking unit with synchronized drive for one printing disc. Diaphragm pump and ink suction pipe for use with original containers supplied by ink manufacturers. 1 set of dedicated ink wipers and guide roller matching the specified printing disc. Complete accessories kit without printing discs. Rugged, virtually maintenance-free AC drive. Incremental tachometer and reference sensor mounted on the printing disc shaft provide exceptionally accurate synchronization. Automatically synchronized stroboscope of extremely high light efficiency allows proper inspection even at slow marking speeds. Electronically synchronized printing disc drive.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

The cable marker KS 42 C-FM is a high-performance marker specifically designed for high-speed gravure printing on hot plastic insulated wires and plastic jacketed cables in user selectable colors. Due to the extremely high precision of the machine’s drive system, the KS 42 C-FM ensures a non-slip operation and a reduction of the strain on the soft cable insulation to a minimum. Marking of text and numbers Single printing head Quick change of legend Print wheel drive up to and above 1200 m/min Exchangeable ink supply system Rugged, virtually maintenance-free AC drive. Incremental tachometer and reference sensor mounted on the printing disc shaft provide exceptionally accurate synchronization. Automatically synchronized stroboscope of extremely high light efficiency allows proper inspection even at slow marking speeds. Electronically synchronized printing disc drive. Integrated control electronics.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

High-performance gravure printing machine with single printing station for marking hot cable insulation. Marking of text and numbers Medium speeds Ink supply system for use with original ink containers Single head STANDARD CONFIGURATION Frame with support column and height adjustment crank mechanism. Marking unit with synchronized drive for one printing disc. Diaphragm pump and ink suction pipe for use with original containers supplied by ink manufacturers. 1 set of dedicated ink wipers and guide roller matching the specified printing disc. Complete accessories kit without printing discs. Integrated ink supply system for use with original ink containers. Quick and easy color changing. Suitable for printing discs with flate or concave rim matching the cable diameter.

Request for a quote

TURAN KIMYA SAN. VE TIC. A.S

Turkey

» Ecoplast Pvc free is the only plastisol printing inks that do not contains phtalates and 100% ecologically organic GOTS certified product. » Plastisol inks in Ecoplast series meet ecologic standards with all printing effects including direct, high density(3D), foam(puff), rubber. » Inks with high opacity and fastness can be used in both manual and automatic systems of printing. » Plastisol printing inks in Ecoplast series cover the requirements of international brands and standards like Inditex RTM, Oekotex 100 Class 1,REACH,Nike,GAP,H&M. » Plastisol inks of Ecoplast series are meeting the high ecological standards, should not be used with other plastisol or water-based products and additives.

Request for a quote

TURAN KIMYA SAN. VE TIC. A.S

Turkey

» Plastoprint phthalate free is opaque plastisol printing inks which contains PVC but free of phtalates. » Easy to get soft handle and opacity in both manual and automatic printing systems . » They give excellent results in High density(3D), rubber, foam(puff), transfer printing applications. » Plastisol inks in Plastoprint series do not contains phtalates or heavy metals.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The JET3up PI is a pigment ink printer primarily used for cables and many other products with dark backgrounds. Data on dark surfaces such as cable must be printed with bright inks. But those present a major challenge for conventional inkjet printers because the pigments in contrast inks settle out. But not with the JET3up PI! The industrial inkjet printer has a unique stirring device that keeps the pigments in motion, thus keeping the ink in the printer always ready for use. This way LEIBINGER guarantees maximum print quality and highest reliability even for the use of pigmented inks. With the automatic nozzle seal "Sealtronic" in the JET3up MI, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quoteResults for

Ink-jet printer - Import exportNumber of results

16 ProductsCountries

Company type