- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- iron and alloys

Results for

Iron and alloys - Import export

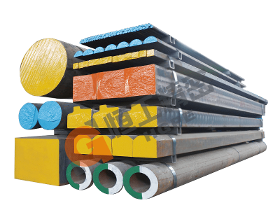

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Iron-based alloys produced by utilizing carbon material groups and containing at least 10.5% chromium are called stainless steel. It is resistant to oxidation due to chromium and maintains its stainless properties.

Request for a quote

ERDOGAN MODA METAL VE PLASTIK SAN. TIC. LTD. ŞTI.

Turkey

We are at your service with zamak , iron , plastic , rivet , eyelet ,rings , special buckles and with surface finishes (color and galvanic finishes) of these products.

Request for a quote

ERDOGAN MODA METAL VE PLASTIK SAN. TIC. LTD. ŞTI.

Turkey

We are at your service with zamak , iron , plastic , rivet , eyelet ,rings , special buckles and with surface finishes (color and galvanic finishes) of these products.

Request for a quote

STRONG ENERGY COMPANY

Turkey

Is a long life concentrate coolant based on ethylene glycol. It is free from amines, nitrites, phosphates and silicates and is formulated using Organic Acid Technology(OAT). Extended Life Antifreeze provides effective protection against corrosion in modern technology engines especially aluminum and alloyed iron engines.

Request for a quote

UNIQUELAB - DISTILLERY SPIRITS & BIOTECH CHEMICALS

Portugal

Alkaline detergent with high degreasing power developed for cleaning iron, alloy, lacquered, painted rims or plastic/metal trim caps. With a specific formulation to remove dirt such as oil residues, brake dust, tar and mud. Do not use on aluminum rims or components.

Request for a quote

HENGONG PRECISION EQUIPMENT

China

The chemical composition data in the table for reference only. 2. The mechanical properties comes from the sample taken from round 1/4 diameter, rectangle & square from 1/4 diagonals. 3. Customized size and grade upon your request

Request for a quote

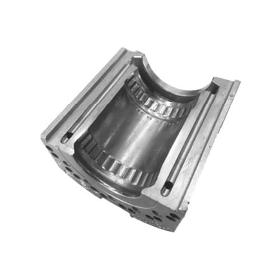

HENGONG PRECISION EQUIPMENT

China

Ductile iron EN-GJS-600-3

Request for a quote

HENGONG PRECISION EQUIPMENT

China

Ductile iron EN-GJS-500-7

Request for a quote

HENGONG PRECISION EQUIPMENT

China

Ductile iron EN-GJS-400-18

Request for a quote

HENGONG PRECISION EQUIPMENT

China

8% lighter than forged steel Machining allowance reduced by 30% 45% reduction in comprehensive cost Tool saving 45%-60% In 1999 Hengong independently developed the first continuous casting line. Compared with other materials, the continuous casting product has fine mic ro-matrix and high yield witho ut internal defect. Currently, Hengong is the major production base of continuous casting iron in Asia. Advantage against forged steel: 8% less weight, 30% less stock allowance, 45% less labor cost, 70% tooling cost.

Request for a quote

OPET LUBRICANTS

Turkey

Extended Life Antifreeze, is a long life concentrate coolant based on ethylene glycol. It is free from amines, nitrites, fosfates and silicates and is formulated using Organic Acid Technology(OAT). Extended Life Antifreeze provides effective protection against corrosion in modern technology engines especially aluminum and alloyed iron engines.

Request for a quote

OEN CHEMICALS GMBH

Austria

Iron Oxide is an inorganic compound. It is a very useful chemical compound which is made up of iron and oxygen. It occurs by the oxidation of iron. Its chemical formula is Fe2O3. Chemical Appearance Iron Oxide has the appearance of a red brown solid. It mostly comes in the powdered form. It is an odourless compound. It is insoluble in water. Chemical Applications and Strengths Iron Oxide is an extremely efficient chemical compound and therefore, has many commercial applications. Its main applications and strengths are: Iron Oxide is most popularly used as feedstock in the iron and steel industries for the mass production of iron, steel, and other alloys. The fine powder of iron oxide is known as rouge and it is used to polish metallic jewellery and lenses. It is also used as a cosmetic. Rouge cuts more slowly than modern polishes but it is still widely used because it gives a superior finish.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AXON CABLE SAS

France

Vibraflame® is a range of cables designed to resist extreme temperatures ranging from -196°C to +1565°C.These fire resistant range of cables do not propagate flame and do not contain asbestos. They can be used as control, coaxial or power feed cables. Axon’ offer extension and compensating cables for thermocouples insulated with vibraflame® material and resistant to temperatures of up to 1050°C. These heat resistant cables can be made with nickel plated copper, nickel alloy, nickel chrome, iron, constantan, copper alloy, cupronickel for extension and compensating cable. They are insulated with a special combination of mica, organic polymers and fibre glass. Applications include power and control cables in steel works, oil refinery, electric furnace, blast furnace,etc

Request for a quote

HIDROMEC SRL

Italy

The steel industry is a specific sub-sector of the stationary industry. The term steelmaking refers to a specific area of metallurgy that involves the technique of processing iron-rich ore to produce iron or various types of ferrous alloys, including steel, pig iron and alloy steels. The steel industry needs very reliable and robust equipment: no malfunction is allowed. Rolling mills and furnaces must not be stopped by a defective hydraulic cylinder. The main features of the cylinders used in this sector, apart from ensuring high reliability, are that they are designed to operate in dusty environments and at very high ambient temperatures, even above 100°C. This makes it necessary to equip the cylinders with seals that retain their functionality even at such high temperatures. Seals and gaskets made of special fluorocarbonate material (Viton) are used. HIDROMEC develops hydraulic cylinders and systems for applications in the steel industry that are reliable, durable and comply with the relevant environmental standards.

Request for a quote

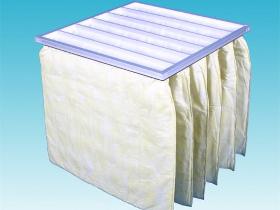

GZ GUANGLI EFE CO., LTD.

China

Large dust holding capacity High filter efficiency Breathable Long working life Good ventilation Application: Used in high temperature, high cleanliness, high air flow dryer environment. Type: pocket filter Frame: aluminum alloy or stainless steel EN779 class: F6,F7,F8,F9 Temp.Resistance: 120℃~≦170℃ Speciality: Galvanized iron or aluminum alloy frame Available in a wide range of sizes, depths and number of pockets. Available as a MERV 8, 11, 13 and 15 Open throat design for optimum air flow Low initial pressure drop and superior dust holding capacity Galvanized steel header and J-channels for filter strength

Request for a quote

GZ GUANGLI EFE CO., LTD.

China

Medium non-woven fabric pocket filter: Large dust holding capacity High filter efficiency Breathable Long working life Good ventilation Application: It is applied to some equipments and systems like oven which the clean air is required; Medium efficiency anti-static pocket filter. Type: pocket filter Frame: aluminum alloy or stainless steel EN779 class: F5,F6,F7,F8,F9 Temp.Resistance: 100℃ Humidity: 100% Speciality: Galvanized iron or aluminum alloy frame Between each pocket has a metal stick to make frame,and the separation material of each pocket can avoid the filter over expanded under the pressure. Ultrasonic sealing make the filter more strong and not easy to broke. Adopt fine synthetic fiber instead of some fiberglass material. Material has Antistatic fiber,large dust holding capacity and long working life. Pocket mesh efficiency has five different type for choice:35%,45%,65%,85% and 95%

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

At AMETEK Specialty Metal Products we produce high purity nickel-iron alloy strips, which are primarily used for reed switch systems. These products are widely used in the automotive market for BMS (Battery Management Systems), improved safety in proximity sensors, and cable harness testing. Alloys Our strips are produced using nickel-iron compositions, making sure to use source metals with market leading low levels of trace elements. Alloys include: Nickel-Iron compositions from 36% to 65% Nickel. Sizes Strip thicknesses down to 0.002” (0.0508mm) and wire diameters as small as 0.005” (0.127mm). Applications Finished nickel-iron alloy reed switch systems are used within a multitude of products and devices, mainly being used in the Automotive and Electronics industries. Automotive: BMS (Battery Management Systems), automatic braking assists, door sensors and speedometers.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our Nickel-Iron alloys are engineered to the ASTM F30 standards for sealing materials and their specified coefficients of thermal expansion. These materials are generally used as the sealing material to bridge the difference between two materials of differing expansion rates during heating and to maintain a hermetic seal. These Nickel-Iron Strip Products are generally used in glass to metal sealing applications ranging from light bulbs to hermetically sealed integrated circuits as well as electrical applications such as switch-gear connections and reed switch systems. Nickel Iron alloys include Invar®, alloys 42, 46, 48 and 52. Others available on request.

Request for a quote

RIMA HEATING SYSTEMS

Turkey

Rima brand flexible cast iron slices Wide range of capacities (from 20 kw to 95 kW) Can be used with wood and coal Chimney flap and simple chimney traction control

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Precision C is a heat treatable Nickel-Iron Alloy used in critical diaphragm applications, such as, metal diaphragms for aerospace sensors and burst discs. The alloy composition provides a unique constant elastic modulus value over a temperature range of -50ºF to 150ºF. Precision C can be readily formed from the annealed temper. It has a work hardening rate similar to austenitic stainless steel. The material can be joined by TIG, EB, and resistance welding as well as by brazing and soft solder technique. The heat treatment of Precision C can be adjusted to produce the desired value for the thermoelastic coefficient at or near zero. The elevated strength in the heat treated temper results in low mechanical hysteresis and low drift. Available Sizes: Precision C is available from Hamilton Precision Metals as strip product in thickness from 0.0005” to 0.040” (0.0127 mm to 1.016 mm) and widths up to 8.0” (203.2 mm). The material conforms to ASM 5221 and UNS N09902.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® Ni 36 is a Nickel-Iron alloy with the lowest thermal expansion of any active alloy from -240°C to 330°C. It is selected when dimensional changes from temperature variation need to be minimized in electronic control devices, such as use within airbag igniters and precision metal stampings. The alloy can be readily formed from the annealed temper.Annealed hardness can be modified to approximately DPH 180 for best blanking characteristic. Grain size can be adjusted to provide the optimum deep drawing characteristic. It can be welded and brazed using conventional methods. Available Sizes: HPM® Ni 36 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.025” (0.0127 mm to 0.635 mm) in widths up to 12.0” (304.8 mm). It is also available in foil as thin as 0.000100” (0.00254 mm) in widths of 4.0” (101.6 mm) maximum. The metal conforms to UNS K93603, ASTM F1684.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Rodar® is an Iron-Nickel-Cobalt alloy with an unique linear thermal expansion coefficient. It is also stable to cryogenic temperatures. This combination of characteristics has prompted its application in electrical package sealing of glass/metal and ceramic/metal. Rodar® can be formed and deep drawn from the annealed temper. A 1/8 hard temper is optimum for heavy piercing.The material can be joined to other metals by welding, brazing, and soldering. The joint design must consider that Rodar® has a lower expansion coefficient than most other metals. Available Sizes: Rodar® is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.060” (0.0254 mm to 1.524 mm) and width up to 12.0” (304.8 mm). The material conforms to ASTM F15, AMS 7728 and UNS K94610.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® Ni 52 is a Nickel-Iron alloy with a thermal expansion characteristic that corresponds to soft glass. Applications include magnetic reed switches and seals that need controlled linear expansion to about 1000°F. The alloy is readily formed or deep drawn from a fine grain annealed temper. Joining can be accomplished by conventional welding or brazing techniques. Useful magnetic characteristics can be produced from a continuous strand anneal. Available Sizes: HPM® Ni 52 available from Hamilton Precision Metals as strip product in thickness from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). The material conforms to UNS N14052.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® Ni 42 is a Nickel-Iron alloy with a thermal expansion coefficient suitable for matching to the ceramic chip in numerous miniature electronic circuits The alloy is readily formed from the annealed temper and can be welded or brazed by standard methods. The alloy is not corrosion resistant at 20°C when exposed to a moist or salt-containing atmosphere. Available Sizes: HPM® Ni 42 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM F30 and UNS K94100.

Request for a quoteResults for

Iron and alloys - Import exportNumber of results

57 ProductsCountries

Company type

Category

- Steel & Metals (11)

- Iron alloys (6)

- Cast iron items (6)

- Cold rolled steel strips (3)

- Steels, nickel (3)

- Casting, steel (2)

- Filtering equipment and supplies (2)

- Steels and metals - forming and cutting (2)

- Lubricants, industrial (1)

- Anti-corrosion products, chemical (1)

- Cutting - machine tools (1)

- Disinfectants, non-medical (1)

- Electric cables (1)

- Fire alarms and detection - equipment and systems (1)

- Fuels, solid (1)

- Greases, industrial (1)

- Hydraulic equipment (1)

- Import-export - chemicals and pharmaceuticals (1)

- Iron, steel and metallurgy - import-export (1)

- Lubricants for cars (1)