- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechatronics

Results for

Mechatronics - Import export

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Alignment Table AT is a rotary positioning mechanism capable of precise angle correction, in which a high rigidity steel table and bed are used and IKO Crossed Roller Bearings are incorporated in the bearings supporting the table. Alignment Table AT uses the ball screw drive to convert linear motion into circular motion in a fixed angle range and positions the table in the rotational direction. An IKO Linear Way L is used for the linear motion rolling guide of the ball screw drive mechanism, combined with a precision ball screw to achieve high precision positioning. Placing Alignment Table AT on the slide table of the IKO Precision Positioning Table enables the configuration of a low height XYθ multiaxis positioning mechanism. This enables the table to be used as an alignment table for precision measuring equipment, inspection equipment and assemblers.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Precision Positioning Table LH is a highreliability, highprecision and highrigidity positioning table made of a cast iron slide table and bed with high rigidity and excellent vibration damping performance, incorporating an IKO Linear Way and using a precision ball screw for the feeding mechanism. By incorporating two Linear Ways in parallel, it achieves stable running accuracy, high positioning accuracy and large carrying mass. It is available in four sizes ranging from 120 mm to superlarge 420 mm in table width, and tables combining these in a twoaxis specification have also been serialized. It is optimum as a highprecision positioning mechanism for usage where the applied load is large and the stroke length relatively long.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Using IKO CLube Linear Way L for the linear motion rolling guide and IKO Crossed Roller Bearings in the rotation guiding parts, while adopting direct drive method in the drive section, IKO Alignment Stage SA···DE is a compact, lowprofile alignment stage which achieves XYθ motion.Alignment Stage SA···DE achieves highly accurate positioning without backlash by combining a highresolution linear scale and full closed loop control. An ideal positioning mechanism for alignment processing using image processing, such as in semiconductor/liquid crystal manufacturing equipment, or for measuring instruments or testing and inspection equipment requiring clean environments.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

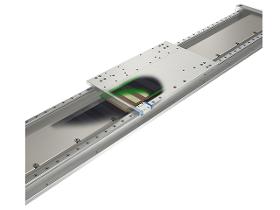

The IKO Linear Motor Table LT is a compact and highprecision positioning table made of aluminum alloy, with an optical linear encoder built in and an AC linear servomotor incorporated between moving table and bed. Three series (Compact Series LT···CE, Long Stroke Series LT···LD and High Thrust Series LT···H) are available and can be selected according to the application. The lightweight moving table and large thrust force of Linear Motor Table LT enables operation with high acceleration/deceleration and high response. Further, the advanced servo technology achieves high static stability and speed stability. Linear Motor Table LT is ideal for applications such as semiconductors and liquid crystal related equipment, measuring instruments, assemblers and conveying machines that require highspeed work.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a moving magnet type linear motor table with a magnet and optical linear encoder scale in the steel moving table part, and a stator coil and optical linear encoder head in the steel bed. For the table guiding parts, an IKO Linear Way, wellestablished in the area of miniature linear motion rolling guides, is used in combination with a linear motor and highresolution linear encoder to realize highly accurate positioning. Thanks to the adoption of highperformance neodymium magnet, large thrust force can be acquired and therefore highspeed and highly responsive positioning is possible, despite its very small body. In addition, high cleanliness is realized as the mechanical contact part is only the linear motion rolling guide thanks to adoption of a landmark driving method without cables. Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear is a moving magnet type linear motor table with a magnet and optical linear encoder scale in the steel moving table part, and a stator coil and an optical linear encoder head in the steel bed. For the table guiding parts, an IKO Crossed Roller Way, wellestablished in the area of miniature linear motion rolling guides, is used in combination with a linear motor and highresolution linear encoder to realize highly accurate positioning. Thanks to adoption of a highperformance neodymium magnet, large thrust force can be acquired and therefore highspeed and highly responsive positioning is possible, despite the very small body. In addition, high cleanliness is realized as the mechanical contact part is only the linear motion rolling guide thanks to adoption of a landmark driving method without cables. Nano Linear is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and electronic

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a compact linear motor table with excellent functionalities, such as a magnet and optical linear encoder scale in the steel moving table part, and a stator coil and an optical linear encoder head in the steel bed. For the table guiding parts, the adoption of CLube Linear Way ML, which realizes long term maintenance free use, helps reduce the maintenance work. Despite its very small body, the rotator exerts a maximum thrust of 36N by adopting a highperformance neodymium magnet, enabling highspeed, highly responsive positioning. Highcleanliness can be realized as the mechanical contact part is only Linear Way. Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and assemblers which require a clean environment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Elevating Table TZ is an elevating table that performs precision positioning in the up and down directions by using the wedge mechanism.The wedge mechanism applied IKO Linear Way has achieved both high accuracy and high rigidity with a compact size.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

The IKO Alignment Module AM is a positioning module developed for alignment stages by combining high rigidity Crossed Roller Bearings and Linear Way E with Precision Positioning Table TU. Alignment stages can be configured without adjusting the height of each alignment module, since the height tolerance is managed with high accuracy of ±10 μm.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Micro Precision Positioning Table TM is an extremely compact precision positioning table incorporating a precision grinding ball screw with a thread diameter of 2 mm and an IKO Micro Linear Way L with a track rail width of 2 mm, wellestablished in the field of ultrasmall equipment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

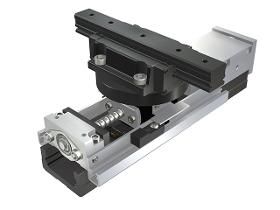

IKO Precision Positioning Table TE is a lightweight and compact positioning table using highstrength aluminum alloy for its main components, with a slide table assembled inside a Ushaped bed. A precision ball screw is used for the feeding mechanism, enabling highreliability and highprecision positioning. Lubrication part CLube is built into the linear motion rolling guide and ball screw, achieving long term maintenance free performance and reducing lubrication work. Various specifications such as ball screw lead, motor type and sensor mounting can be configured, enabling the optimum positioning table to be configured according to the application. Ideal for a wide range of applications ranging from equipment that requires high positioning accuracy such as parts machining, assembly, inspection and conveying equipment through general conveying fields.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

TU Series is a compact and slim type positioning table, consisting of a Ushaped track rail and a slide table. The slide table assembled inside the Ushaped track rail is an integral part of a linear motion rolling guide mechanism, in which two rows of large diameter steel balls are arranged in four point contact with raceways. Owing to this design, stable high accuracy and high rigidity are obtained in operations even under fluctuating load varying in direction and magnitude and complex load. Also, by adopting a Ushaped track rail, the rigidity of track rail under moment load and torsion is greatly improved. TU Series includes six sizes with a track rail width of 25 mm to 130 mm. For each of them, slide table length can be selected. Also, ball screw types and leads, motor types, and sensor installations, etc. can be selected to obtain an optimum positioning table suitable for each application.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Precision Positioning Table LH is a highreliability, highprecision and highrigidity positioning table made of a cast iron slide table and bed with high rigidity and excellent vibration damping performance, incorporating an IKO Linear Way and using a precision ball screw for the feeding mechanism. By incorporating two Linear Ways in parallel, it achieves stable running accuracy, high positioning accuracy and large carrying mass. It is available in four sizes ranging from 120 mm to superlarge 420 mm in table width, and tables combining these in a twoaxis specification have also been serialized. It is optimum as a highprecision positioning mechanism for usage where the applied load is large and the stroke length relatively long.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Precision Positioning Table LB is a highspeed movementenabled, long stroke positioning table that adopts a highly durable and hightensile timing belt containing steel cord incorporated into the feeding mechanism of the slide table, and uses a high torque 5phase stepper motor as the driving motor. The slide table and bed are made of lightweight highstrength aluminum alloy. Two sets of IKO Linear Way are incorporated into the linear motion rolling guide in parallel, realizing stable and high running performance. Precision Positioning Table LB is ideal as a positioning mechanism, for assemblers, conveying machines or pallet changers that work at high speed.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a linear motor drive high thrust pick & place unit with compact integral X and Zaxes, using IKO CLube Linear Way ML in the table guiding parts. Thanks to the adoption of a system which drives the moving table with a link mechanism, it realizes both higher thrust of the linear motor and weight reduction of the moving parts and reduces tact time. By entering a positioning program, you may set flexible operation patterns and change strokes easily according to the workpiece. IKO Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and electronic parts assembling machines which require a clean environment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Super Precision Positioning Table TX is a positioning table with extremely high accuracy which is created based on the high precision, high rigidity and well proven IKOPrecision Positioning Table LH by using cylindrical rollers for rolling elements and incorporating IKOLinear Roller Way Super X, which has bestinclass running performance as a linear motion rolling guide, with fullyclosed loop control. Optimal for highly accurate positioning where the existing rolling guides could not be used.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Positioning Table L is a lightweight, long stroke positioning table configured with the slide table and bed made from highstrength aluminum alloy. High accuracy and carrying mass are realized by incorporating two sets of IKO Linear Ways in parallel, and using a precision ball screw in the feeding mechanism. Maintenance work such as relubricating with grease can be reduced significantly by CLube. Various table sizes and stroke lengths are available, and dedicated XY brackets are also serialized, enabling systems such as orthogonal robots to be easily configured according to the application. Precision Positioning Table L is ideal as a highprecision positioning mechanism, for assemblers, processing machines, or measuring instruments.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Cleanroom Precision Positioning Table TC···E is optimal for use in high cleanliness environments for semiconductor and LCD manufacturing machines. The unique highairtight structure seals the driving part and guiding parts of the slide table, and prevents dust generation around the table. IKO Cleanroom Precision Positioning Table TC···E achieves cleanliness class 3 by enhancing the airtightness inside the table.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

Relay is an automatic switch element with isolation function, which is widely used in remote control, telemetry, communication, automatic control, mechatronics and power electronic equipment.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

Relay is an automatic switch element with isolation function, which is widely used in remote control, telemetry, communication, automatic control, mechatronics and power electronic equipment.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

Relay is an automatic switch element with isolation function, which is widely used in remote control, telemetry, communication, automatic control, mechatronics and power electronic equipment.

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

GENERAL OPERATION The machine is built-up of a rotating plate and a knot device that allow to create the requested wire ties. When the cycle is running, the pinch roll insert the wire in the machine and the rotating plate starts to rotate creating the wire ties. The crossed ends of the wire are held together and twisted by rotation of the gripper. AUTOMATIC CYCLE When the operator press the “start” button, the automatic cycle command is sent to the machine. This signal allow to insert the wire into the rotating plate following the sequence below: - Realignment and lifting of the twister. - Realignment of the wire step cylinder. - Closing of the pinch roll. - Moving forward of the puller. - Insertion of the wire by means of forward rotation of the pinch roll. When the twister is in high position, the puller is moved forward, in order to pull out the wire ties. With a time delay, the machine starts a new tying cycle (according to the number of the ties set in the operator’s panel).

Request for a quoteResults for

Mechatronics - Import exportNumber of results

23 ProductsCountries

Company type