- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- paint stripping

Results for

Paint stripping - Import export

SMITO-TECHNIC GMBH

Germany

SMiTO TECHNIC is highly specialized in the field of paint removal technology and thus able to design and develop individual systems exactly tailored to your specific paint stripping tasks. Wherever our standard systems do not match your needs, we can develop creative solutions for the most-varied of requirements. In doing so, we attach special importance to plant safety and high quality.

Request for a quote

SMITO-TECHNIC GMBH

Germany

Suitable for water-based paint strippers with operating temperatures of up to 90 °C. Modular design for the highest level of safety and (if needed) customization to the desired height of the spraying chamber. Electronics and paint stripping agent tank in separate "technical module." Uniform coating of the workpieces through the use of a nozzle system in the spraying chamber, consisting of needle-nose jet nozzles and flat-jet nozzles and a rotatable cage for the workpieces. High loading capacity by virtue of the cage diameter of 1500 mm and effective interior height of 2100 mm; max. cage load: 750 kg. Stripping agent tank: 1000 liters for long effective life of the medium, indirect electrical heating. All parts coming into contact with the media are made of stainless steel. Easy operation with clearly arranged displays and operating controls. High-quality Siemens control for monitoring the paint stripping process.

Request for a quote

SMITO-TECHNIC GMBH

Germany

Scalable system, consisting of paint stripping, rinsing, conveyance of the workpieces, and (optional) vacuuming. Multitank systems can be manufactured on the basis of the TB400 or the TB1000. The basic unit is a system consisting of 1 paint stripping tank, 1 rinsing tank, drip station, semi-automatic conveyance system, and vacuum (optional). On this basis, we can design systems with various different paint stripping tanks (e.g., for different kinds of paint stripping agents), with one or several rinsing tanks, and (optionally) vacuuming for connection to the customer's waste gas disposal system.

Request for a quote

SMITO-TECHNIC GMBH

Germany

Lifting aid with smooth hoist to lower / raise the racks (sieve basket, hooks, wire mesh crates, or similar) holding the workpieces into / out of the tank. This facilitates loading and unloading at a comfortable height, and without any direct contact with the chemicals.

Request for a quote

SMITO-TECHNIC GMBH

Germany

Dip tank for long workpieces or for high piece numbers Dip tank with integrated safety sump tray and stainless steel cover (insulated). Easy to open using manually operated hoist.

Request for a quote

SMITO-TECHNIC GMBH

Germany

Lifting aid with smooth hoist to lower / raise the racks (sieve basket, hooks, wire mesh crates, or similar) holding the workpieces into / out of the tank. This facilitates loading and unloading at a comfortable height, and without any direct contact with the chemicals.

Request for a quote

SMITO-TECHNIC GMBH

Germany

The dip tank TB400 is the smallest model in our line of paint stripping systems. It is ideally suited for wheels / light-alloy rims, bicycle and motorcycle frames, painting aids or hooks. Insulated, double-walled dip tank ("vat-in-vat" system) with insulated top cover, indirect electrical heating, circulating system, and high-quality safety and monitoring technology.

Request for a quote

SEMIN

France

TECHNICAL DEFINITION • White fine grain repair filler for interior and exterior use • Does not shrink • High resin content • FINEX SYSTEM is a multi-purpose filler, which allows to fill holes and cracks, and to repair windowsills and damaged angles ACCEPTED SUBSTRATES Cement, concrete, bricks, concrete blocks, stone, aerated concrete, plaster, old paint, old tiling. SUITABLE SURFACES Once completely dry, FINEX SYSTEM can be covered with all types of paint, watertightness system, plaster- or cement-based fillers, and silicate, epoxy or polyurethane paint. TECHNICAL CHARACTERISTICS • Grain size : fine • Adhesion : complies with standard DTU 42.1 • pH : 9 once dry • Setting starts after 50 minutes • Setting ends in 1 hr 10 min PREPARATION OF SURFACES BEFORE APPLICATION The substrate must be clean, dry, free of dust and of any trace of stripping oil. Walls that are peeling off must be scraped beforehand. Strip any old paint in poor condition and remove any old thick plastic covering.

Request for a quote

WOMA GMBH

Germany

The highpressure pumps of the Z series deliver operating pressures up to 1,500 bar. With a high number of pressure and nominal flow rate combinations, the pumps are preferably used in industrial cleaning, paint stripping and also in descaling.For pumps with an operating pressure of more than 1,000 bar, hard metal plungers are used, which are particularly stable in order to guarantee a long service life and thus low maintenance costs.

Request for a quote

WOMA GMBH

Germany

The Magnet Lizard is unbeatable when it comes to the effective cleaning, decoating or paint stripping of large areas, e.g. ship hulls, tanks and larger steel structures. It adheres magnetically to any magnetic surface – horizontal, inclined, vertical or overhead. Remotely controlled and selfpropelled, the Lizard makes scaffolding unnecessary and so reduces the costs to a minimum. With working pressures of up to 3000 bar and a working width of up to 400 mm, the Lizard ensures precise working and high area efficiency. The Magnet Lizard is especially suitable as an accessory for WOMA devices in the Advanced and Expert series.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dissolving of a wide range of sealants and adhesives such as polyurethane residues, materials containing epoxies Elimination of oily and greasy soiling Removal of bitumen and tar splashes Dissolving of labels and adhesive strips Removal of paints on a PMMA and PU resin basis from metal surfaces Advantages and benefits Good infiltration of adhesive films allows easy removal of the residues from the surface Good washable with water after use Applicable to surfaces of metal, stainless steel, glass, wood, ceramics. Do not apply on sensitive materials such as PVC, PS or on painted surfaces Low effect on the climate and no negative influence on the ozone layer (ozone-depleting potential: ODP = 0) Free of surfactants, halogenated and aromatic solvents

Request for a quote

ASP

France

Paint stripping by high-pressure water blasting is very aggressive: splash back from jets, paint flakes, etc. For this reason, ASP has developed some original and effective solutions to keep your robot clean and to preserve its condition. Made from coated fabric, ASP’s covers are always the ideal solution for your robot protection problems. They are well-suited to painting processes (silicone free).

Request for a quote

ASP

France

Paint stripping by high-pressure water blasting is very aggressive: splash back from jets, paint flakes, etc. For this reason, ASP has developed some original and effective solutions to keep your robot clean and to preserve its condition. Made from coated fabric, ASP’s covers are always the ideal solution for your robot protection problems. They are well-suited to painting processes (silicone free).

Request for a quote

LABOREX

Belgium

Ditch the old-school method of cleaning parts and switch to Laborex immersion parts washers! Our washers provide a comprehensive solution for cleaning, degreasing, rinsing, phosphate treatment, passivation, oiling, paint stripping, and drying of both metal and plastic parts - all in a closed cabin. Our immersion process involves both cold and warm immersion, and we offer the added option of brushing, spraying, or blowing the parts dry. This ensures that your parts are not only perfectly clean, but also dry and ready for use in no time. Say goodbye to the hassle of manual cleaning and hello to the convenience and efficiency of Laborex immersion parts washers.

Request for a quote

LABOREX

Belgium

The Laborex immersion parts washers clean, degrease, rinse, phosphate, passivate, oil, strip paint and dry metal and plastic parts. The parts are cleaned in a closed cabin by means of cold and warm immersion with the option of brushing, spraying or blowing the parts dry.

Request for a quote

BLASQEM, LDA.

Portugal

We offer high quality and reliable paint stripping rooms, with different configurations adapted to the requirements of each client. In collaboration with partners with more than 30 years of experience, with engineering and their own manufacturing resources, we study the best technical solutions to meet the expectations of our customers. The blasting rooms supplied by Blasqem can meet different requirements and have different configurations, namely: Shot blasting with several operators Automation of the operation (e.g. robots) Workpiece lifting systems High brightness Double pressure tanks Large capacity depots Different systems and levels of recirculation Magnetic separation ATEX systems No space required We also offer mobile stripping rooms. These solutions can include a complete and compact system for blasting, filtration and recirculation of abrasives.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Application example: Paint stripping of wheel rims in a little while Application - example: Paint stripping of wheel rims with Clean-o-mat RC-E and biological high tempterature paint stripping agent, single or per set, depending on machine size.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

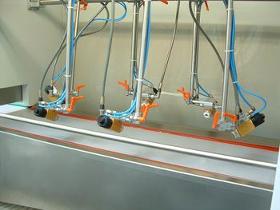

To conform to market requirements, widely differing machines for painting/coating mouldings, window parts and other profile components were developed. The type and number of guns depends both on the paint system and on the quality envisaged. Air, Airmix or Airless spraying systems can be used for this purpose. The individual machine types can be configured with all conveyor systems of our portfolio and combined with the respective drying systems. The difference between the VEN SPRAY MOULD (LT) and (LW) variants is their type of extraction. LT stands for dry extraction, LW for water-backed extraction. VEN SPRAY MOULD COOLAC is exclusively designed for processing water-based paints. The overspray is constantly collected and condensed in chilled collector systems. The condensation of the controlled air humidity keeps the collector devices and chilled conveyor systems permanently wet. This reliably prevents paint particles from drying during operation. The strip painting plants can be supplemented by further Venjakob plant technologies specifically tailored to the process such as brush sanding/denibbing machines, dryers or conveying equipment.

Request for a quoteResults for

Paint stripping - Import exportNumber of results

19 ProductsCountries

Company type