- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pfa coating

Results for

Pfa coating - Import export

FLUOROCARBON SURFACE TECHNOLOGIES

United Kingdom

We have a wide range PFA coating products to suit your application, PFA can be applied as a thin film or high build coating depending on your project requirements. Properties and Applications of PFA include: Chemical resistance Chemical Process Vessels Pharmaceutical Process Equipment Laboratory Equipment/Glassware Medical Laboratory Equipment Chemical Seals & Diaphragms Non-stick Heater Platen’s Heat Seal Bars & Cutters Cookware & Bakeware Food Processing Machinery Cryogenic Applications, (Liquid Gas Connectors & Valves) Bursting Discs Food Moulds

Request for a quote

ADTECH POLYMER ENGINEERING

United Kingdom

Fluoroplastics are the most inert materials known to man and ideal for the protection of components in applications where highly corrosive or solvent conditions exist. We offer a fluoroplastic encapsulation service, and we encapsulate any item in FEP, PFA and PTFE. Fluoroplastic encapsulation service range: - Encapsulating components with FEP - Encapsulating components with PFA - PTFE Teflon® Spray Coating For more information, visit the adtech.co.uk website or contact us: t: +44 (0)1285 762000 e: sales@adtech.co.uk

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

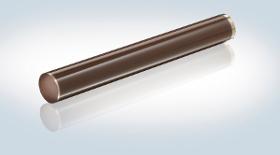

The requirements: long life good thermal capacity of silicones non-stick top coatings precise tolerances for runout, diameter and coating thicknesses without surface grinding

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

KB RollerTech processes seamless metal belts (stainless steel and nickel). Compared to coated plastic belts, metal belts offer the following advantages: very high thermal conductivity very high physical stability Today, KB RollerTech processes metal belts with the following properties: Properties Nickel belts Stainless steel belts Length < 350 mm < 400 mm Diameter 15 - 50 mm 10 - 100 mm Wall thickness 30 - 500 µm 35 - 100 µm Geometry straight straight and concave Remarks 100 mm diameter only possible with seam Concerning the coatings the following combinations are possible: Nickel belts Stainless steel belts PFA sleeves PFA spray coatings or PFA sleeves Silicone and PFA sleeves Silione and PFA spray coatings or PFA sleeve

Request for a quote

NANJING LAB

United Kingdom

Binzhenghong hotplate is a digestion or acid drive equipment commonly used in elemental analysis laboratories. It is made of aluminum alloy or graphite, which heats up quickly and uniformly. Teflon PFA coating on the surface for effective corrosion protection. Its advantage is humanized customization(Its size can be customized according to the requirements of laboratory decoration). Exquisite details:The power cord is sheathed with PFA sleeves and no exposed metal parts, which minimizes interference to the experiment and has a longer service life. It has 4 strengths: 1. heating speed, full uniform heating 2.high efficiency,can heat several samples at the same time 3.simple operation, easy to use. Long service life 4. can customized different holds according to different utensils

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUOROCARBON SURFACE TECHNOLOGIES

United Kingdom

Our range, based on high performance melt processable fluoropolymers such as ECTFE coating, PFA coating and ETFE coating has been formulated to provide enhanced toughness and chemical protection. F-LON® High Build surface coatings have been specifically developed to satisfy the most demanding requirements of the processing industries including organic and inorganic chemical manufacture and the food processing and pharmaceutical industries. Our internal reinforcement technology also enables application thicknesses in excess of 1.0mm (depending on the component) further enhancing liquid and vapour resistance. Desired thicknesses are attained by the application of multiple spray coats with high-temperature oven-fusion cycles between each coat. Rotation of parts during coating minimises the effects of thermoplastic melt flow.

Request for a quote

HEUTE + COMP. GMBH + CO

Germany

Coatings made of PFA and PVDF fluorine-based thermoplastics provide safe protection against corrosion even on exposure to aggressive media. Because its molecular structure resembles that of PTFE, PFA is almost universally resistant to chemicals. Other special features of PFA linings are their wide range of operating temperatures and easy cleaning due to the material’s non-adhesive nature. In many applications, this makes it possible to replace stainless steel with a raw material which is not only much more economical but also easier to process. Because coatings are applied in a thermoplastic transfer-moulding process, it is necessary to account for certain design aspects which our team will gladly discuss with you in advance.

Request for a quoteResults for

Pfa coating - Import exportNumber of results

8 ProductsCountries

Company type