- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sawing machines for wood

Results for

Sawing machines for wood - Import export

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola building site table saw ZBV 500 S with height and tilt adjustment and safety guard. The new ZBV 500-S is a height and tilt adjustable building site circular saw with a 500 mm saw blade. The ZBV 500-S also enables bevel cuts with a high cutting height on the construction site. Above all, the increasingly used insulating material can be optimally processed in connection with the AVOLA special circular saw blade HM / A / PH (see above).

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As with the paper industry, because of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges woodlands, the wood processing industry is the third key industrial sector that has driven our growth. Among many other customers, we work with the leading manufacturers of MDF panels and reels for the storage and transport of electrical cables Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the upgrading of existing production plants to reduce set-up and adjustment times and increase productivity conveyor systems wood cutting systems (sawing) wood sanding systems wood nailing and assembly systems Applications and projects : conveyor systems wood cutting systems (sawing) wood sanding systems wood nailing and assembly systems robotic units Related operations on customers’ sites : maintenance of equipment and infrastructure repairs

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

As a market leader for circular building site saws and with more than 80 years of experience, we know what is important. With this knowledge, we work continually to keep products up to date, thereby offering the highest-quality, most durable and safest machines.Changes in the machinery directive For improved safety, we have developed a safety hood that has proven to significantly reduce occupational accidents as part of the revision of standard EN 1870-19 prior to the amendment of the Machinery Directive 2006/42/EC. This was awarded the EURO Test Prize of the EU Builder's Trade Associations. Since the new machinery directive went into effect in 2010, all new circular building site saws have been equipped with the newly improved safety hood and other essential safety components and have been delivered exclusively in this version.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

REVOLVING CROSS CUT SAW WITH NC PROGRAMMING SYSTEM GAMA 65 K3 Fully automatic circular saw for positioning and controlling via touchscreen with length measuring system EXENSO COMFORT (Pusher system) Application Length stop system (pusher operation), revolving table and sawblade inclination via servo - motor for positioning ( cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Technical Equipment : - Motor rating 8,1 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Sawblade height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT – sawblade 650 x 30 x T 54 - Dust extraction spigot 125 / 80 mm - Revolving table 20° - 160° - Horizontal material clamping system, right - left - pneumatische Kappvorrichtung über ZweihandSteuerung/vollautomatisch

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Standard equipmentwith tilting alu sliding table 1000x800 mm Cutting height 424 mm Cutting length 700 mm Roller diameter 500 mm Saw band length 3720 mm a) for three-phase current 400 V, 50 Hz, motor power 1,3 KW b) or alternating 230 V, 50 Hz, motor power 1,3 KW only saw band, to be selected according to the type of stone material with jack rings and 2 rollers Sound emission Lpa according to DIN 45635, part 1651 on gas concrete and lightweight refractory bricks ...75 dB(A) on Poroton ...................................... 88 dB(A) Size LxWxH: 1000x1000x1800 mm Weight: 130 kg

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Due to the built-in ball screws, our CNC Router High-Z/T achieves an extremely precise accuracy and an almost no longer measurable backlash of about 0.01mm. In addition, high travel speeds of up to approximately 108mm per second (6500 mm per minute) can be achieved. Installation of protective housing and the suction socket is necessary for CE-compliant commissioning of our CNC machines.

Request for a quote

YILMAZ MACHINE

Turkey

KD 305 portable miter saw machine is designed for straight and angular cutting of PVC, aluminum and wooden profiles. Location points at 45°- 30°- 22.5° -15°- 0° both left and right Pivoting range from 45° left to 45° right infinitely adjustable Lateral and longitudinal cutting feature on the upper table Strong spring system and protective shield STANDARD ACCESSORIES Profile support 1x horizontal clamp OPTIONAL ACCESSORIES MKN300 or MKN150 roller conveyors MS TYPE OF Machine stand Ø 300 mm saw blade

Request for a quote

DISPA MACHINE

Turkey

Double Column Bandsaws with linear guideways are ideal for MITRE cuts with different quantities. With the movement of the bow, it’s possible to cut between 90° and +45°. With height adjustment and hydraulic cutting, control allows the bow to go up over the material after the cut. All this process is controlled by a digital counter on the control panel and total duration for one cut decreases. Fixing the bow at any angle is controlled by the hydraulic brake system.

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -Comes with a stop rod for repeatable cuts -24 V low voltage system -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Hassle-free performance

Request for a quote

PROSAW LIMITED

United Kingdom

The Metlsaw NF range of plate saws are the premier saw for precision sawing of non-ferrous plate from 6mm – 300mm thick. Fully automatic sawing system Up to 12" thickness capacity 50 HP Arbor Motor Positioning (cut to length) tolerance to +/- 0.075mm Surface Finishes to 8 Micro-inch High speed close tolerance cutting Can eliminate/reduce secondary machining of parts Fast set up and part number memory Rapid sawing speeds Full size touchscreen operator interface PLC Controls by Rockwell Automation (AB) Easy Blade Change Available widths of 1.8M – 6M as standard

Request for a quote

PROSAW LIMITED

United Kingdom

The NCH plate saws are designed for quick and accurate cutting of bars and plates into strips of varying widths. This allows you to reduce inventories of cut-to-width stock and increase the flexibility of your sawing operation. Models are available in a wide range of sizes. High-productivity Automatic machines, with moving arc from 4 to 6 meters cutting length.

Request for a quote

PROSAW LIMITED

United Kingdom

The Bomar Workline 410.280DGH is a semi-automatic mitre bandsaw and is an ideal basic model for the production of steel structures. The both-sided mitre cuts continuously adjustable within the 0–60° range, with a large, easy-to-read angular scale. This machine features also an easily movable clamping vice for mitre cuts and a full-stroke hydraulic vice with a tightening system. Bomar Workline 410.280DGH Standard Details: 2 way mitre – 60° right, 60° left Easy to read mitre scale DRO for mitre angle Long stroke hydraulic vice Powered bow raise Adjustable back off valve for optimising downfeed speed relative to material mass Control box mounted on swinging arm Simple, robust push button controls Variable blade speed 20 to 120m/min Dovetail sliding vice for mitre cutting 27mm blade width Bed height: 756mm

Request for a quote

PROSAW LIMITED

United Kingdom

Heavy Duty Automatic Bandsaw for solid bar, bundles & general sawing with the following features: Vice feed automatic with encoder for precision length set Twin hydraulic vices clamp both sides of material Simple input of component length and number of pieces via touch screen Steplessly variable blade speed 17 ~ 67m/mm Hydraulic blade tension control for optimum blade life. Variable downfeed control. The touch sensitive control screen provides easy selection of precise bar length requirement for a precise cut off length. The auto head-elevation reduces index cycling time significantly. The Blade speed is set and adjusted by acting on the touch sensitive control screen. There are quick-adjusting carbide saw-band guides, there is an idle wheel motion protector, a hydraulic band tension control, a quick-action HYDRAULIC twin-vice (split vice) 3-jaw clamping, a unique two-way vice jaw and an automatic chip conveyor.

Request for a quote

PROSAW LIMITED

United Kingdom

This Semi-Automatic Vertical Bandsaw is a large capacity machine that cuts aluminium, ferrous and non-ferrous materials.

Request for a quote

YILMAZ MACHINE

Turkey

DC 550 SK is a full automatic sawing machine which is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminum materials by means of double head sawing units equipped with Ø 550 mm of saw blades. Two-hand safety operation Equipped with CNC control system for precise angular adjustment Tilting range inwards 45° and outwards 22.5° Hydro-pneumatic saw feed Cutting accuracy +/- 0.1 mm 2 x pneumatic profile supports Windows based industrial PC and 15’’ LCD touch screen color monitor Facility to transfer the cutting list at ‘mdb’+'xls' format via USB and network Remote connection via internet and providing technical support Barcode printer & image print Automatic slicing feature Profile height measuring system (DC 550 SKH) The angle setting of the heads is ensured with servo control system The position setting of the moving head is en sured with servo control system STANDARD ACCESSORIES Equipped with saw blades 2 X Ø 550 mm

Request for a quote

PROSAW LIMITED

United Kingdom

Karmetal OSA 300x380 PLC Technical Details: • PLC control panel • Heavy duty construction • Hydraulic vice • Mechanical top clamps • Inverter controlled blade speed 25 to 90m/min • Hydro mechanical blade tension • Fast approach • Adjustable hydraulic regulation of the bow descent rate • Inverter driven blade speed • Swarf conveyor • 1.4 metre roller conveyor

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

With our saws and profile processing centers, we are able to precisely cut sheet metal and profiles on request. Elumatec DG244 double miter saw for lengths of up to 6000 mm, high-quality cutting of profiles made of aluminium, PVC and light metal alloys. Cutting profiles made of aluminium, PVC and non-ferrous metals with our SBZ-151 5-axis profile machining center from Elumatec.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROSAW LIMITED

United Kingdom

Bomar Ergonomic 275.230DG Standard Details: Heavy duty one-piece cast bow Precision control hydraulic downfeed Substantial vices, quick set lever operation Bow rotates 45-90-60° Easy to read mitre scale Carbide blade guide pads and rollers Heavy duty blade tensioning unit Heavy duty, 3 phase motor Re-circulating coolant pump Adjustable guide arm Heavy duty gear train Blade speed: 35 & 70 m/min 500mm length stop included

Request for a quote

YILMAZ MACHINE

Turkey

SK 450 is designed for the strait cutting operations of the large size of profiles made of PVC and aluminum by means of Ø450 mm of saw blade at 90°. It is ideal for the serial and precise slicing operations. Suitable for high-volume slicing of aluminum profiles for window manu facturing and industrial applications High precision servo motors and inter nationally recognized components Saving of time by means of servo con trolled workpiece infeed speed and saw blade stroke Horizontal and vertical clamping of the workpiece during the sawing operation Automatic table retraction feature that moves the cut material a small amount after cutting and before the blade came back down to prevent the re-cut & scratches High cutting accuracy by means of the robust mechanical structure Programmable spray saw blade lubrication system via control panel Large memory capacity for the cutting programs The machine shut down automatically after reaching the requested quantity

Request for a quote

ADAÇAM MACHINE AND BAND SAW FACTORY

Turkey

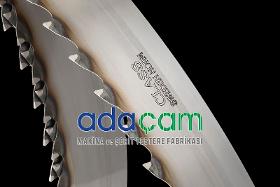

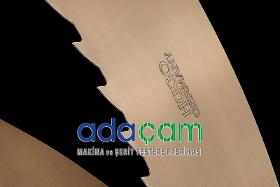

A BAND SAW COVERED BY STELLIT WHICH PROVIDES EXCELLENT SURFACE OPTIMUM REGULARITY AND CONTROLLING CUTTING

ADAÇAM MACHINE AND BAND SAW FACTORY

Turkey

A BAND SAW MADE FROM A HIGH QUALITY OF GERMANIAN STEEL C75 S

PILANA METAL S.R.O.

Czech Rep.

Bimetal band saw blade with extra wear resistance Application: cutting steels with tensile strength up to 1700 MPa high alloy steel and stainless steel titanium alloys and nickel hard machined materials Characteristics.

Request for a quote

INSTRUMENT I KOMPLEKTUYUSCHIE (LLC)

Russia

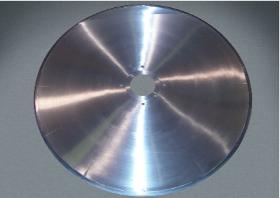

This type of disc knives is especially popular on the equipment of the Italian company Gamma Meccanica SpA. main size is D800/d100, suitable both for cutting plates and for trimming edges. The main advantage of this disc is that no abrasive dust is formed while using it.

Request for a quote

DISPA MACHINE

Turkey

• Semi-automatic double miter for cutting profiles and solid material in steel and non-ferrous material and an excellent price-performance ratio • Manually swiveling saw frame with hydraulic clamping for optimal • Hydraulic clamping of the horizontal vise • Automatic saw frame raising on the cut end • Double speed motor 1.0/1.3 KW Gearbox • Sensitive cutting pressure regulation function of the material properties • Hydraulic-mechanical belt tension • Tape guide with hard metal pads sheets and rolls • Thermal overload protection and no-volt release • Automatic shut-off after cut end • Automatic belt break protection Driven

Request for a quote

ERKFEN MACHINE

Turkey

WOODEN PALLET RECYCLING MACHINE Wood pallet recycling machine performs the separation process in order to re-evaluate the used new pallets and to be revised for use in the market when they become idle. The general principle in this separation process is to cut the nail/staple materials that connect the parts. It is an important requirement that forest products, which are the consumable raw materials of the pallet industry used in loading and transportation, are used in the most efficient way by using them in a longer term. USE IT IN GOOD DAYS…

HENAN RICHI MACHINERY

United States

Capacity: 0.3-4.5T/H (Single Machine), 0.3-90 T/H (Full System) Application: Biomass Pellet Plant, Wood Pellet Factory, Fuel Pellet Plant, Lumber Factory, Furniture Factory, Pine Cat Litter Factory, Etc. The raw materials of RICHI wood chip press machine come from a wide range of sources, including chips, sawdust, shavings, bark, sanding powder, waste wood log, and branches produced in wood processing and wood-based panel production. Various types of straw produced after crop harvest and other types combustible biomass can also be used as raw material, without adding any adhesive, and wood pellet fuel can be produced through equipment processing.

Request for a quoteResults for

Sawing machines for wood - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Sawing machine tools (14)

- Blades for saws and cutting machines (6)

- Cutting - steels and metals (2)

- Construction - portable power tools (1)

- Industrial tools (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Milling - woodworking machinery (1)

- Motor mechanics - hand tools, non power (1)

- Panels, chipboard (1)

- Power saws, portable (1)

- Wood veneer - machinery and equipment (1)