- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- solder resist

Results for

Solder resist - Import export

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

Despite its very small size, the IST AG FemtoCap humidity sensor has excellent sensor characteristics that are required in areas such as automotive and white good applications. In combination with external electronics, it offers an excellent cost to performance ratio. The FemtoCap is an optimal cost efficient sensor solution and is capable of measuring 0 % RH to 100 % RH (maximal dew point +85 °C) with a capacitance of 180 pF ±50 pF (at 30 % RH and +23 °C) and operates within a temperature range of -50 °C to +150 °C. Further advantages of the P14 FemtoCap capacitive RH sensor include: — High chemical resistance — Very low drift — Wide temperature range — Excellent price-performance ratio — Resistance to condensation — Solderable and bondable (fully automated assembly) — Fast recovery time — Customer-specific sensor available upon request

Request for a quote

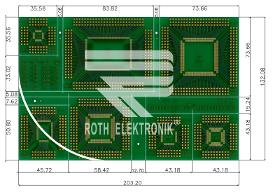

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 1.50 mm Double-sided 35 µm Cu Plated through holes (PTH) Surface chem. Ni/Au with solder stop mask Pitch 0.40 mm (15.7mil) and 0.50 mm (19.7 mil.) Adaption board for 23 different SMD-QFP s Hole diameter 1.00 mm Prescratched rated break point for the separation of individual modules from the board Gerber data for manufacture of the solder resist masks and the soldering paste imprint will be provided free of charge on request Size 132 x 203 mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Application: Mainly applied to the electronic soldering iron Voltage: 110VAC Heating Resistance: 310Ω±10% Dimension: L60*φ3.8mm Electrode: Welding 2 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Usage: Mainly applied to model 933 electronic soldering iron Voltage: 220VAC Heating Resistance: 140Ω±10% Dimension: L60*φ3.8mm Electrode: Welding 4 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification: Application: Used for 936 soldering station Voltage: 24VAC Heating Resistance: 3.0±0.3Ω (23℃±2℃) Dimension: L60*φ3.8mm Electrode: Welding 4 nickel wires on the surface

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 436 is a corrosion and heat resistant ferritic Chromium Steel. It can be polished to appear similar to Chromium plate. The material is magnetic in both annealed and cold rolled tempers. This grade of ferritic stainless steel has shown a greater resistance to ridging or roping defects as compared to type 430 stainless steel. The alloy can be readily blanked and formed. The material can be resistance welded, brazed, and soldered. SS 436 is resistant to atmospheric corrosion and fresh water, but it not resistant to most salts and seawater. It is resistant to scaling by oxidation up to about 1400°F. Available Sizes: SS 436 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 15.0” (381 mm). The material conforms to ASTM A240 and UNS S43600.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 430 is a corrosion and heat resistant ferritic Chromium Steel. It can be polished to appear similar to Chromium plate. The material is magnetic in both annealed and cold rolled tempers. The alloy can be readily blanked and formed. The material can be resistance welded, brazed, and soldered. SS 430 is resistant to atmospheric corrosion and fresh water, but it not resistant to most salts and sea water. It is resistant to scaling by oxidation up to about 1400°F. Available Sizes: SS 430 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM A240, FED QQS 766, and UNS S43000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Phosphor Bronze A is a Copper base spring material with a good combination of strength, formability, and corrosion resistance. The material is suitable for use in certain contact springs and diaphragms. The alloy has good formability up to moderate strength. It can be soldered, silver brazed, and resistance welded. Available Sizes: Phosphor Bronze A is available from Hamilton Precision Metals as strip products in thicknesses from 0.001” to 0.020” (0.0254 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM B 103 and UNS C51000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM ® 270 Nickel is the highest purity Nickel. The controlled low impurity level provides uniform and repeatable mechanical, electrical, and magnetic properties. The material has excellent corrosion resistance with high thermal and electrical conductivities. A high thermal coefficient of electrical resistance makes it suitable for strain gauges, temperature sensors, and electronic components. The alloy can be formed by all conventional cold forming methods, and can be joined by resistance welding, brazing and soldering. The corrosion resistance is generally very good in most mediums, although, it is subject to intergranular embrittlement by sulfur compounds above 315°C Available Sizes: HPM ® 270 Nickel is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.020” (0.0127 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). It is available as foil as thin

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM 233® Nickel is a commercially pure wrought Nickel with low carbon. The material has excellent corrosion resistance with high thermal and electrical conductivities. A high thermal coefficient of electrical resistance makes it suitable for temperature sensors, and electronic components. The alloy can be formed by all conventional cold-forming methods and can be joined by welding, brazing and soldering. The corrosion resistance is generally very good in most mediums, although it is subject to intergranular embrittlement by sulfur compounds above 315°C. Available Sizes: HPM 233® Nickel is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.020” (0.0127 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). It is available as foil as thin as 0.000100” (0.00254 mm) in 4.0” (101.6 mm) maximum width. The material conforms to ASTM B162, ASTM F3, and UNS N02233.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® 201 Nickel is a commercially pure wrought Nickel. With low carbon, the material has excellent corrosion resistance with high thermal and electrical conductivities. Making it perfect for use in flexible metal foil heaters. The alloy can be formed by all conventional cold-forming methods and can be joined by welding, brazing and soldering. The corrosion resistance is generally very good in most mediums, although it is subject to intergranular embrittlement by sulfur compounds above 315°C. Available Sizes: HPM® 201 Nickel is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.020” (0.0127 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). It is available as foil as thin as 0.000100” (0.00254 mm) to 4.0” (101.6 mm) maximum width. The material conforms to ASTM B162, and UNS N02201.

Request for a quote

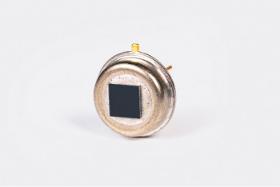

MICRO-HYBRID ELECTRONIC GMBH

Germany

The MTS1HIGHTEMP is a high-sensitivity, single-channel thermopile detector for precise, non-contact temperature measurement. Tanks to the housing with a soldered filter the detector is resistant to humidity, aggressive gases and other environmental influences. The high detectivity of up to 12.2*10^8 cm√Hz/W and the high sensitivity of up to 501 V/W are achieved by back gassing with krypton and the special chip design. Influences by humidity in the measuring environment are eliminated by a filter used in the transmission range from 8 to 14 µm. These properties allow the use in applications with high requirements, such as temperature monitoring of thermally indexed process parameters in the metal industry or testing of maintenance-relevant properties in the solar semiconductor industry. The detector can be used at ambient temperatures between -20 and 180 °C. An integrated thermistor for intrinsic temperature monitoring can compensate external temperature influences.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TITANIUM The new generation of wave soldering systems – lead free soldering without corrosion. TITANIUM is the innovative soldering solution developed by STRECKFUSS SYSTEMS. It uses titanium, an agent which is extremely lead free solder resistant. For this reason, titanium works perfectly in lead free soldering processes. An oxide film immediately covers all material damages and thus prevents corrosion. In contrast to wave soldering systems with stainless steel components, titanium is not subject to corrosion even when lead free solder is used. By means of a simple and safe solder bath exchange, TITANIUM makes it possible to switch flexibly from a standard soldering process to lead free production. This ensures maximum flexibility at minimum costs and easy handling. TITANIUM is a complete system and includes: Spray fluxer with extraction hood Double wave 3- D wave (for the prevention of solder bridges) Infrared preheating Microprocessor controls Soldering frame transportation system

Request for a quoteResults for

Solder resist - Import exportNumber of results

14 ProductsCountries

Company type