- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding machine repairs

Results for

Welding machine repairs - Import export

ALPHA LASER GMBH

Germany

The ALM laser system is particularly suitable for welding large molds and tools, housings and machine components - wherever mobility and maneuverability are required. With the ALM you have exactly the mobility you need for welding. No matter whether in your own workshop or on site at the customer. The laser is ready for use within a few minutes. The arm can be quickly adjusted to the area to be welded and fixed in the desired working position using electro-hydraulic brakes. The operator then has the option of welding manually using a joystick or semi-automatically. One or more axes are automatically moved at a preset speed and with the joystick curves can be driven or small corrections made.

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

ALPHA LASER GMBH

Germany

The desktop laser welding machine delivers with 50 watts good beam power and is characterized by its uniform, powerful, yet soft welding behaviour. The manual welding laser VL 50 has a very spacious working chamber and allows to weld precious metals such as silver and gold due to its powerful laser behaviour. Longer concentrated work is easily possible thanks to the ergonomically designed housing with the well thought-out arrangement of keyboard, display and joystick. The desktop laser VL 50 is a valued tool in the manufacture and repair of dentures and jewelry, in welding on precision parts, medical technology components and sensors, but also when applying materials to small molds.

Request for a quote

ALPHA LASER GMBH

Germany

You won’t get it more flexible. The mobile welding laser AL-ARM was developed to quickly and flexibly repair offset seams, pores and penetrations in the car body. The fiber laser system can be positioned quickly and has a long range. The 3D visualization with integrated laser safety glasses enables the user to observe his welding task as well as the surroundings. The welding process is shown enlarged and the process-relevant data is also visible in the image. The handpiece, which is used for welding, is equipped with an automated wire feed and an integrated shielding gas nozzle. It weighs just 1.5 kg and is easy to position. There is no set-up time for welding.

Request for a quote

ALPHA LASER GMBH

Germany

The ALFlak systems offer you many options in the field of mobile laser and repair welding. With an extended range and increased travel range, welding positions in deep, complex shapes can be processed easily thanks to the long laser arm - even in deep, bulky shapes. Deposition welding with wire or powder is possible with this laser machine. Likewise, automated welding tasks. The laser device is equipped with a fiber source that guarantees high efficiency and a special beam quality. Both pulsed and CW mode can be used. The integrated performance monitoring ensures reproducible welds. This system is available with laser powers of 300/450/600 and 900 watts.

Request for a quote

ALPHA LASER GMBH

Germany

The ALW is a comfortable, ergonomic, and compact seated workstation that offers plenty of legroom, and which can be adjusted to the height of the operator via the height-adjustable foot plate. The observation lens offers a variable viewing angle from 10° – 50°, thus ensuring comfortable working. The closed, laser-proof housing makes the ALW a laser-protected workplace that can be used in a normal production environment without additional safety precautions. The laser system is easy to operate. In addition to configuring via the display, the laser parameters can be adjusted via the patented multifunction footswitch or adapted accordingly during welding. The large doors of the ALW can be opened wide. This facilitates easy loading.

Request for a quote

EWM AG

Germany

TIG inverter welding machine with high frequency start. Thanks to the modular structure, the machine can be retrofitted with an additional water block without using any tool. With the two available control variants (Smart 2.0 or Comfort 2.0), a variety of functions are available: — TIG Liftarc welding without HF — MMA pulsing — TIG pulsing (sec/kHz) up to maximum 15 kHz — TIG AC welding — TIG AC pulsing (sec/special) — Non-latched/latched operation — Adjustable up-slope and down-slope time — Adjustable gas pre- and post-flow time — MMA welding — Adjustable hot start current and hot start time — Adjustable Arcforce — Antistick function Available as DC and AC/DC variant with optional torch connection for standard start/stop welding torch or up/down torch.

Request for a quote

EWM AG

Germany

— Inverter welding machine, DC — Very light-weight, only 4,7 kg – housing made of aluminium and impact-resistant plastic — Portable, shoulder strap — MMA and TIG lift arc welding — Cellulose electrodes: 100% safe for vertical-down welding — Welding of stick electrodes up to 4 mm — Pulsed MMA welding: — Especially suitable for root welding — Outstanding gap bridging with no sagging of the root side — Fine-flaked weld surface with a TIG look for final passes — Less finishing work thanks to less spatter — Ideal for difficult electrodes — Less distortion thanks to controlled heat input — Pulsed TIG welding with up to 2 kHz — Connection capability for remote control — IP23 spray water protected — Arcforce, hot start, antistick — Energy efficient due to standby mode — 3.5 m mains lead with 16 A earthed plug — Overvoltage protection: No damage to machine caused if inadvertently connected to 400-V mains voltage

Request for a quote

EWM AG

Germany

— Degaussing of pipes and metal sheets — Automatic degaussing before welding — Dependable degaussing for better welding results through stable welding process without magnetic deflection, minimisation of finishing work — activgauss (10–250 A) – degaussing during welding: — Avoids moving up of magnetic field during the welding process in case of very long and strongly magnetised components — Portable and robust — Quick connection at the pipe by means of three load cables — Use at -25 °C to +40 °C with mains voltage tolerances of +/- 20% Advantages of degaussing: — No deflection of the arc by residual magnetism in the workpiece — Prevention of lack of fusion due to insufficient sidewall fusion — Minimisation of finishing work — Cost-efficient and high-quality results — Set: Degauss 600 degaussing machine, two 5-metre, 35 mm² load cables, one 20-metre, 35 mm² load cable, RT DGS1 remote control and 5-m connection cable

Request for a quote

EWM AG

Germany

Maximum operating convenience, long service life and all pulse, standard and innovative welding processes optimised and included in the machine at no extra charge. The members of the Titan XQ family are taking a quantum leap in welding technology. Here, perfect weld seams are already pre-programmed for low- and highalloy steels and aluminium in all material thicknesses and all positions. Thanks to the many options and accessories for the Titan XQ puls series, you can put together your machine in the way that best suits you, your needs and your applications. An exceptionally long duty cycle of 100% at up to 350 A, for example, makes for effective working. Perfect welding becomes sustainable – 24 hours a day, 7 days a week.

Request for a quote

EWM AG

Germany

— GMAW standard and pulsed welding — Synergic characteristics for steel, CrNi and aluminium — MMA welding and TIG liftarc welding — Perfect for welding self-shielding flux cored wires — Infinitely adjustable arc dynamics (choke effect) — Synergic or manual welding operation — Interval welding — Adjustable gas pre- and post-flow time — Portable, compact — Saves power through highly efficient performance — Robust casing suitable for construction site use — 4-roll drive for 0.8 mm and 1.0 mm steel wires — Easy, tool-free change of welding polarity — IP23 spray water protected — Wire spool diameter up to 200 mm/D200 — 3.5 m mains supply lead with 16 A shock-proof plug — Mains connection 230 V/16 A — High mains voltage tolerance +15%/-40% and therefore fully generator-compatible — Free WPQR package for certification up to and including EXC2 in accordance with EN 1090 and for welding of unalloyed steels up to and including S355

Request for a quote

ADMET SP. Z O. O.

Poland

We offer laser cutting of: - Structural steel - up. to 15mm thick - Stainless steel - up to 8 mm - Aluminum - up to 8 mm

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Achieving a cutting tolerance of +-0.25mm, lasers are firmly established as the accurate cutting technology. Capable of achieving fine contours and intricate cuts in seconds, laser cutting is leading the way in manufacturing efficiency gains.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Our laser tube cutting service includes all major tube and section profiles – including large tube laser cutting – with specialist profile capabilities accommodated with ease. Continuous investment ensures we can always offer our customers the broadest capabilities, so they remain at the forefront.

Request for a quote

YILDIZ POLIETILEN LTD. CO.

Turkey

We produce electrofusion machines that can weld diameters from 20mm to 1600mm.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Welding construction as required No matter whether pipes, small parts or large components - the welding construction department of Siempelkamp Maschinenfabrik GmbH is able to fulll your wishes thanks to its high-performance machinery. Our welding specialists are able to produce your components using MIG, MAG, UP, TIG, Emanual and electro-slag processes. Numerous certicates attest to the highest quality of our welding work. Key features procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Advantages procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Application of the most ecient welding process for your component Highest quality standards through certied welding work economic production of tubes by our forming and necking machine

Request for a quote

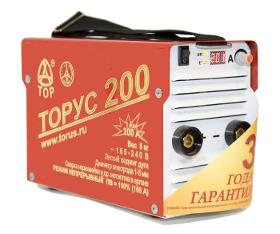

COMPANY TOR

Russia

ТОРУС-200 is a modern welding inverter device based on a digital high-frequency mains voltage transducer. The device is designed for electric arc welding of low-carbon, alloy and stainless steels, it can operate in TIG and MMA modes. Obtaining high-quality welding joints does not require high qualifications from the employee, which is important for novice welders. In short-circuit mode, the device almost does not consume current, which allows it to be powered from petrol power units with a capacity of 4 kW (6 kVA) and a household network with slumps up to 165 V. ТОРУС-200, like other inverter welding machines of the ТОРУС line, allows you to get welding with stable parameters. It is characterized by: small weight – 5 kg, high performance factor and the ability to work with electrodes with a thickness from 1.6 to 5 millimeters. In addition, the ТОРУС-200 welding inverter is designed for continuous operation not only indoors, but also outdoors.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

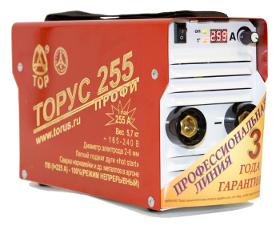

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

KLN ULTRASCHALL AG

Germany

The KLN QSW 400 L is a modular laser welding machine. The advantage of the modular structure is that the central laser welding machine can remain unchanged in the various welding tasks and only the housing and its frame structure must be adapted to the actual welding task. Thus, a well-tried laser welding unit can always be used. Moreover, adaptions to other welding tasks can be easily integrated, e. g. with rotary table, tool carrier, conveyeor or sliding table. Laser: Water-cooled diode laser with 300 W optical output power Wave length 980 nm ±10 nm Pilot beam at 650 nm ±15 nm (<1 mW) Optical fibre suitable for wave length 780-1030 nm Focal distance of collimation 58 mm Focal distance f-theta objective 635 mm Operating distance 728 mm Operating field (scan field) 415 mm x 415 mm

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

EKO circular welding systems are designed for circular pieces’ integration with various welding methods in different positions. It appeals to a wide usage area in which all of the welding techs single and multipass welding tig, mig/mag and submerged welds can be used. It is used in environmental and linear welding of materials like circular formed, boiler, thermosiphon, hydraulic cylinder, conveyor roller, conveyor wheel, solar power boilers etc. It increases output and gain with the savings of materials and time. Upon request, production is made on different diameter, height and features

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

It’s designed upon you weld cylindrical, conical and rectangle shaped bended frameworks and in shape of flat slab metal sheet and plaque linearly. Frameworks that are between 200-3000 mm diameters can be welded on different types of machines easily. Its production can be made from the length of 0.5 meter to 4 meters. Upon customer demand the length can be increased. As to application method, TIG, MIG and submerged welds can be adapted. Materials’ like boiler, thermosiphon, solar power boilers, cooling tanks, natural gas funnels, lpg tubes etc., height welds are made on this machine.

Request for a quote

PI-METÁL

Hungary

Our latest additions to the line are the Swiss Bystronic Fibre Laser Cutting Machine 3 kw) and Bodor Precision Laser Machines 150 W, CO 2 We provide quality, high precision laser cutting and engraving service on a very competitive price This cutting method is very cost and time effective Products are highly customizable, unique shapes and various materials can be cut, such as plastic, wood, metal, etc.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

The Frame Welding Machine is made of welded parts of different sizes and is designed to obtain the desired special H profiles. The machine body and the welding heads are fixed and the workpiece provide to be welded on both sides of the part to be welded by moving by means of driven conveyors. The hydraulic cylinders in the system provide the positioning of the H profile placing and fixing during welding.The system has adjustable backrests and accessories for the roofing of the conveyor group.The system has a hydraulic piston loading unit. The system might turn beam 90 degree with maximum weight and maximum dimensions by means of chain or mechanical structure.

Request for a quote

SNOWBIKE LLC

Russia

Fiber optic welding machine L-WELD is designed to weld metal plates and pipes. Fiber laser creates a high-frequency beam, which is focused in one spot. This concentrated laser source provides thin, deep welding and is of high speed.

Request for a quote

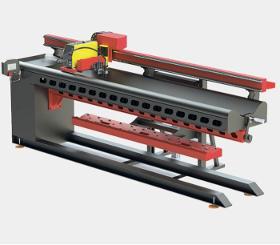

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Length Welding Machine is designed for length welding of cylindrical, conical and rectangular bent parts and flat plate sheet metal and plates. Parts between 100-3000 mm diameter can be welded on different machine types. The length welding machine, which offers the ability to make welds internally and externally, is produced from 1 meter to 4 meters long. In some special cases, the length may increase even more. Currently, workpieces with a minimum wall thickness of 0.60 mm can be welded. In submerged arc applications, the wall thickness is up to 20-25 mm. Boilers, water heaters, solar energy boilers, cooling tanks, natural gas chimneys, LPG tubes etc. Length welds of materials are made on this machine. Submerged arc, gas metal, tig etc. Welding systems work synchronously with our machine.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Being able to walk on a suspended type tank Single-sided tank welding Single operator control 1000 – 3000 mm plate welding Tank welding machine is an automatic tank welding machine designed for welding cylindrical structures that can weld with submerged arc welding in the side position (3 o’clock). The welding unit is fixed on a cabinet. On the upper floor of this cabin, where all safety conditions have been provided for the operator, there are motor and gear systems that move the system on the hardware sheet. Tank Welding Machine enables horizontal circumferential welding of large storage tanks with Submerged Arc welding machine. • The minimum diameter it can weld is 4.5 meters. • The lowest sheet thickness that can be welded is 6 mm. The outer cover is produced to protect the user from the external factors of nature. Our Tank Welding Machine is designed to weld either internally or externally.

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

YILMAZ MACHINE

Turkey

Machine is ideal for welding process of PVC plastic profiles at four corners. Fully automatic four corner welding of PVC window profiles at an angle of 90° Welding of a complete window frame or sash in one cycle All profile related welding parameters are individually programmable User-friendly operating system compatible to all optimization programs Parameters are set easily by means of 8’’ LCD color touch screen Automatic line can be made by combining with Cooling Unit (SA 250),Corner Cleaning Machine (CNC 608-610) and Rotating Robot (SA 260) Automatically setting of standard (2 mm) or seamless (0.2 mm) welding options Long time of Teflon using period by means of the roller system Automatically discharging of the frames after welding operation Colored and white profiles selection modes Saving of time by means of practical mold change system Operator safety barrier Adjusting the heat between 0-300°C via electronic thermostat Minimum welding measurement : 400 x400 mm

Request for a quoteResults for

Welding machine repairs - Import exportNumber of results

29 ProductsCountries

Company type