- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixing plant

Results for

Mixing plant - Import export

ELKON GMBH

Germany

Being produced in ELKON’s latest tech production facilities, mobile continuous mixing plants (pugmills) can be easily transported via axle and tyres installed on the main unit. Thanks to its superior mobile design, these plants are installed on a flat concrete surface without foundation requirement and can be relocated easily so that the user doesn’t have to travel long distances for material transportation. These mobile pugmill plants are mainly used for for subbase (stabilization) material with / without cement production and RCC concrete for dam or road pavement projects. Mobile continuous mixing plants, also known as WOLF in ELKON’s product range, are equipped with 5000/2500 l. ELKON continuous twinshaft mixer. All materials are mixed passing through ELKON C200 mixer continuously according to the recipe and flow speed.

Request for a quote

ELKON GMBH

Germany

Being produced in ELKON’s latest tech production facilities, stationary continuous mixing plants (pugmills) are mainly used for subbase (stabilization) material with / without cement production and RCC concrete for dam or road pavement projects. Equipped with 5000/2500 l. capacity ELKON continuous twinshaft mixer, there two models of pugmill plants, 300 tons/h and 500 tons/h capacity. In this mixing plants, thanks to aggregate bins equipped with dosing belts, it’s possible to adjust material flow rate by means of frequency inverters. Cement flow rate can also be precisely adjusted by a screw equipped with frequency inverter whilst the water flow by a proportional valve. All materials are mixed passing through ELKON C200 mixer continuously according to the recipe and flow speed.

Request for a quote

UMMANMAK

Turkey

Asphalt plants create the hot mix material by mixing different types of aggregate, bitumen and filler. The advantage of our continuous type asphalt plants is production high quality asphalt, because of very sensitive dosing with accordance to recipe accepted in your country. - Number of different aggregates : 4-5-6 - Mobility : Stationary and Mobile type - Capacity offered : 80 - 120 - 160 tph - Hot asphalt storage bunker : optional - Bitumen tanks : you can purchase from us, as well as from domestic market - Aftersale Service : can be provided from Turkey and Algeria - Operation System language : English - Russian - Turkish - French You can contact us any time. We can speak in English, Russian, Turkish, French and Arabic to make you feel comfortable.

Request for a quote

ROBINSON CO.

Turkey

Pellet sieves, take the oath pelletized powder pellet press again sends to the upper reservoir. pellet separated from the dust, Sent to the finished product silos. Depending on the space 2 or 3 cassette and 2 or 3 It is produced as output. Manufacturing is done in two separate models; vibrating screen and rotary screen. the centrifugal force will occur due to vibration and shaking vibration body vibration minimizing the special chassis system for dust separation, characterized in pellet diameter kullanılmaktadır.h. Dust sealing özelliği.kolay be changed 2 or 3 There ply sieve tray system. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

ROBINSON CO.

Turkey

The pellet crusher is a crusher specially designed to break 03-5mm granules into small pieces. With this design, the quality of pellet feed and pellet feed is improved. It is mainly used for poultry and fattening pellets and aquaculture pellets. The pellet crusher has two rollers, the working distance of which can be adjusted (manually or by motor). Thanks to the specially designed abilene rollers, all kinds of grains are processed with high capacity and quality. These rollers can always be used correctly to ensure high efficiency. The roller mechanism is fed regularly by the power supply unit. The pellet is evenly distributed over the entire surface of the roller. Thanks to a regular feeding with this mechanism, a homogeneous structured feeding with a low power and a lower dust content is obtained without overloading the machine. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

KASAG SWISS AG

Switzerland

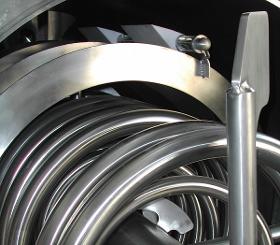

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The heat resistant wiper has been specially developed for hot goods and high ambient temperatures, as this wiper is absolutely heat resistant up to 270 degrees. Suitable for drying drums (e.g. in asphalt mixing plants and lime plants).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH Brush strip wipers are made of highly wear resistant PP and are ideal for demanding applications in the field of bulk material, recycling and processing technology. The brush strips can be exchanged easily and simply when they are worn out. Inexpensive alternative for cleaning light conveyor belts in the lower belt without electric drive easy construction continuous brush strip easy adjustment by moving the spindle Areas of application sand, gravel, clay, brickworks, asphalt mixing plants, gypsum, cement, glass industry and much more

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK curved scraper is for use on light to heavy conveyor belt systems. The curved solid carbide bar of Curved standard stripper has particularly in the center of the conveyor belt a high wiping effect and relieves the pressure on the outer edges. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK HM inner belt scraper is for use on light to heavy conveyor belt systems. High tech hard metal enables a particularly high time of exposure. The HM inner belt scraper prevents the material from settling in the inner belt between the belt and the drum and so damaging the drum. Belt speeds of up to 2 m/s with the mini model. Belt speeds from 2 m/s with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK master cleaner scraper is for use on light to heavy conveyor belt systems. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning. Due to the flexible mounting arrangements and the gentle but thorough cleaning, the FTK Förderband Technik Kilian belt conveyor scrapers lead

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK primary scrapers for pollution abatement in conveyor belt systems The primary scraper is used for light to heavy conveyor belt systems high tech hard metal for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU hard metal segments also specially suitable for reversing conveyors belt speeds up to 5 m/s specially for extremely adherent materials or in difficult or narrow space conditions significantly improved cleaning performance limiting damage to the belt longer life expectancy and therefore significant cost savings due to special segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure) Areas of use sand plants, gravel plants, clay plants, brick plants, asphalt mixing plants and in the gypsum, cement and glass industries etc Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This transducer can be used anywhere thanks to its small size. Designed to work without a measuring chamber (uses a flush front diaphragm instead), this transducer is ideal for any measurements where the material to be measured may leave problematic residues. The range of suitable applications is even greater thanks to a choice of screw-on or weld-on adapters. Areas of use: Bottling plants, food industry Mixing facilities for the chemicals industry Pharmaceuticals Cosmetics industry Bioengineering These miniature pressure transducers are made entirely of titanium and therefore have outstanding resistance to corrosion. These convert the pressure-induced deflection of the diaphragm into a change in electrical resistance, which can be amplified, measured and processed by external electronic circuitry.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Settling and floating layers are avoided by horizontal and vertical mixing. Before plant construction, coordination takes place with the future plant operator to determine the optimum stirring technology based on the respective substrates. Operational safety is ensured by the closed reaction chamber, the external drive for the agitator and the externally mounted electric drives. Variable dimensions and substrate flexible stirring technology also allow the use of difficult substrates. The wall heating system, externally mounted on the fermenter wall, ensures optimum fermentation conditions and a high gas yield. FAST ASSEMBLY – LESS COST Low installation costs are possible by using the Lipp dual seam system and on site production. If the foundation slab is provided along with assistance during assembly, costs fall still further.

Request for a quote

TRBA

Belgium

Our in-house asphalt mixing plant ‘Les Enrobés du Centre’ offers us maximum autonomy and flexibility. This high-tech plant, which also allows for the recycling of hot-mix asphalt, ensures the best quality/price ratio for all your projects. Our team of laboratory technicians is at your disposal to develop compositions that meet your expectations and can take charge of the production process from A to Z

Request for a quote

GEDA GMBH

Germany

GEDA industrial elevators guarantee the smooth, efficient and safe transportation of people and materials precisely where they are required. Even in the toughest of conditions, GEDA products score highly with customers due to their unique quality and modern car design. The versatile deployment sites of GEDA industrial elevators cover cement works, asphalt mixing plants, chemical plants through cooling towers and silos to offshore plants and explosion-protected areas. Industrial elevators create huge time and cost savings due to efficient workflows in maintenance and service work. The GEDA Standard elevator range covers load capacities from 400 to 3,200 kg. The modular design also provides the customer with the choice of different car dimensions and hoisting speeds of up to 60 m/min. Whatever demands an elevator must meet every GEDA industrial elevator, whether a transport platform or personnel and material hoist or pure material hoist, can be perfectly adapted to on-site conditions.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The latest generation of multifunctional YSTRAL PiloTec process equipment offers you the opportunity to use established production processes on a laboratory scale. Thanks to Conti-TDS technology, powder can be inducted, wetted and dispersed under vacuum, dust-free and in a single operation. Easy-to-use swappable tools enable operation using the innovative Multi-Z or Z-Inline process with high-precision multi-stage shear ring systems. Established procedures and a specific energy input independent of the batch size guarantee excellent and consistent results. These can be easily transferred to production scale - a safe scale-up to ystral plant construction. The modular design enables extension to the PiloTec-Plant process plant with ystral mixing technology, systems for handling powders and liquids, measuring technology and sensors, lifting stands as well as other modular components.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CBD HEXAGROUP

Czech Rep.

To enjoy a moment of rest and relaxation, this herbal tea from ASABIO laboratories is the 100% natural drink perfectly suited to allow you to find calm and well-being, thanks to the benefits of nature and CBD. The Cannabidiol present in the herbal tea - CBD Serenity comes from organic hemp grown in Europe, respecting nature, without having to use pesticides or fertilizers. Thanks to its unique method of spraying, the manufacture of our herbal teas are specially designed to bring you the necessary balance in your daily life. Each ingredient is delicately chosen to conquer your palate. Our CBD herbal tea - Serenity will allow you to find calm & well-being thanks to its gourmet recipe mixing CBD with different aromatic plants selected by us: Lemongrass Lavender Sage Coriander Hemp Indeed, recognized for its multiple benefits, CBD from organic European hemp, contains all the recognized active ingredients of this plant with ancestral uses.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine which mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed beds. The machine is commonly used on small fields, gardens and vineyards. It is a tillage machine that crumbles the soil so the seeds will find an easy way to grow. The machine mixes the plant wastes into soil homogeneously. Plant wastes, which are mixed with soil, make the soil more organic and fertile. A skid hydraulic system with a sensor automatically shifts the machine when the machine encounters a tree or a hard material. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540 Gearbox provides 170rpm Rotor Speed -7 mm thick; C type high quality blades. -Transmission set with robust gears -2 slides -Adjustable & Flexible back cover -Hydraulic offset -Automatic skid sensor device -36/42/48 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine which mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed beds. The machine is commonly used on small fields, gardens and vineyards. It is a tillage machine that crumbles the soil so the seeds will find an easy way to grow. The machine mixes the plant wastes into soil homogeneously. Plant wastes, which are mixed with soil, make the soil more organic and fertile. A skid hydraulic system provides the user to shift the machine from the tractor’s control unit when the machine encounters a tree or a hard material. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540 Gearbox provides 170rpm Rotor Speed -7 mm thick; C type high quality blades. -Transmission set with robust gears -2 slides -Adjustable & Flexible back cover -Hydraulic offset -36/42/48 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine which mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed beds. The machine is commonly used on small fields, gardens and vineyards. It is a tillage machine that crumbles the soil so the seeds will find an easy way to grow. The machine mixes the plant wastes into soil homogeneously. Plant wastes, which are mixed with soil, make the soil more organic and fertile. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540 Gearbox provides 170rpm Rotor Speed (1 Speed) -540rpm Gearbox provides min157 max222rpm Rotor speed(4 Speed) -7mm thick; C type high quality blades. -Transmission set with robust gears -2 slides -Adjustable & Flexible back cover -36/42/48/54/60 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

STONEBURIER is a tillage machine which mixes the soil with the help of horizontally rotating hoes. This rotary tiller is used for preparing seed beds on rocky/stony fields and to burry the stones 20 cm below the field surface. The roller ensures a flatter soil surface while working. It is a tillage machine that crumbles the soil, so the seeds will find an easy way to grow. Also it mixes the plant wastes into the soil homogeneously. Since the rotor turns backward, it crumbles the soil on the maximum level. Helps cleaning the stones from the field and prepares the soil for sensitive seeds. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540/750/1000 rpm Gearbox Speed provides min:208 max3:25 Rotor Speed -12mm thick High Quality Blades. -Packer roller with Sludge Separator -Hydraulic Roller Adjustment Kit -Transmission Set with Robust Gears -54/66/72/78 Blades; 6 blades per flange

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine that mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed bed. The rotary tiller is a tillage machine which fully crumbles the soil. Since it turnovers the soil; it causes mixing the plant wastes into soil homogeneously. Special blade angles enable tilling with faster speed even on the hard clods. Rippers in front of the machine ensure easier tillage even in harder soils. The roller ensures a flatter soil surface while working. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540/750/1000 rpm Gearbox provides (2150/2400) min151 max343 (2650/2900/3150) min150 max325 Rotor Speed -8 mm thick high quality blades+ -Cage Roller -Roller Adjustment Kit -Transmission Set with Robust Gears -2/4 Rippers -Removable CE Safety Guards -48/54/60/66/72 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine that mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed bed. The rotary tiller is a tillage machine which fully crumbles the soil. Since it turnovers the soil; it causes mixing the plant wastes into soil homogeneously. Special blade angles enable tilling with faster speed even on the hard clods. Rippers in front of the machine ensure easier tillage even in harder soils. The roller ensures a flatter soil surface while working. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540/750/1000 rpm Gearbox provides min150 max325 Rotor Speed -8 mm thick high quality blades -Cage Roller -Roller Adjustment Kit -Transmission Set with Robust Gears -6 Rippers -Removable CE Safety Guards -78/84/90 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine that mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed bed. The rotary tiller is a tillage machine which fully crumbles the soil. Since it turnovers the soil; it causes mixing the plant wastes into soil homogeneously. Special blade angles enable tilling with faster speed even on the hard clods. Rippers in front of the machine ensure easier tillage even in harder soils. The roller ensures a flatter soil surface while working. -Universal 3point CAT III or CAT IV linkage -1 3/8’’ Z21 Spline PTO Protective Shaft -1000 rpm gearbox speed provides 400 rotor speed -10 mm thick high quality blades -Cage roller -Hydraulic roller adjustment kit -Transmission set with robust gears -3 front rigid shanks -Removable CE safety guards -120/132 Blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer i4MIXACO has been an innovation leader in the mixing industry for years. With the innovative container mixer i4 we are going one step further into the future. Outstanding mixing flexibility, high quality and reduced cleaning effort to a minimum are its outstanding features. Equipped with the new MIXACO Control Center (MCC) we set a new milestone for highly efficient mixing plants. All advantages at a glance * Flat mixing head * Optimized suction * Dust protected machine components * injection through mixer shaft * different container sizes on one mixer * Reduction of cleaning times * Lifting device with container positioning * High flexibility * New tools for more efficient mixing * Lower energy consumption * No base plate

Request for a quote

BEYAZLI GROUP

Turkey

Concrete Batching Plant - Ready Mix Concrete Plant - Concrete Machinery - Concrete Mixer - Concrete Factory |More Economic | Advanced Technology | More Durable | Fast Delivery| Campaign Price: 170.370 EURO (free installation and free staff training) Contact: seher +90 5326382935 (Whatsapp) Warranty: minimum 24 months Capacity: 100 m³ / Hour ready-mix concrete /8 HOURS Transportation : 5 HQ 40' Containers Concrete Batch Plant Ready Mixing Concrete Plant Concrete Mix Machinery Concrete Transportation | More Economic | Advanced Technology | More Durable | Fast Delivery The ready-mix concrete plant or concrete batching plant is designed with a fully automatic operating system. Designed to work 24 hours. This concrete batching plant system is made to produce ready-mix concrete from the mixture of Aggregate, Cement, Water and Concrete additives with specific ratio. The system of concrete batching plant starts operation with the dosage. Video: https://www.youtube.

Request for a quote

BEYAZLI GROUP

Turkey

Concrete Mix Plant - Hollow Block Making Machine - Paving Block Making Machine - Curbstone Making Machine Ready mix concrete plant - Concrete block machine - Paving block machine - Interlock bricks machine - Cinder block making machine - Hollow block machine - concrete block making machine - paving block making machine - interlock brick making machine Campaign Code : C-001 Campaign Price : 52.367 EURO (free installation and free staff training) Contact: Seher +90 5326382935 (Whatsapp Now) Warranty: minimum 24 months Capacity: (8 HOURS) 5.000 Pieces 20 Cm Of Hollow Blocks - 15 m3 / Hour Ready Mix Concrete Transportation : (WITHOUT THE PALLETS ) Max. 1 HQ 40' Container With Single Mortar Hopper - Semi Automatic System - Manual Pallet Carrying System - Fully Automatic Mortar System (Without Hopper And Cement Silos) - Daily Capacity 5.000 Pieces 20 Cm Of Hollow Blocks - 15 m3 / Hour Ready Mix Concrete - Max.

Request for a quote

RATEC GMBH

Germany

The KBV crane concrete distributor is THE transport system for concrete from the mixing plant to the production area. Precise unloading not only saves concrete, but also improves the quality of your finished parts.

Request for a quoteResults for

Mixing plant - Import exportNumber of results

32 ProductsCountries

Category

- Agricultural machines and accessories (7)

- Conveyor belts (5)

- Concrete mixers (2)

- Concrete, ready-mixed (2)

- Flour milling - machinery and equipment (2)

- Brick-making - machinery and equipment (1)

- Concrete forms (1)

- Concrete preparing - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Construction cranes (1)

- Herbs for medicines and cosmetics (1)

- Hoists and elevators, construction (1)

- Mechanical engineering - custom work (1)

- Metal brushes (1)

- Mixers and grinders for the food processing industry (1)

- Peat and compost (1)

- Plastics - machines and material for industry (1)

- Sensors (1)

- Steel sheets and strips (1)

- Tanks, metal (1)