- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nozzles - ferrous metal

Results for

Nozzles - ferrous metal - Import export

KAMAT GMBH & CO. KG

Germany

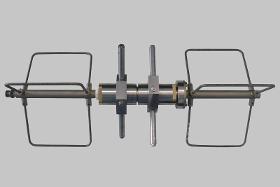

The nozzle consists of two counter-rotating nozzle housings into which the nozzle tubes are inserted with a connection for screw-in round jet nozzles. A special packing sealing system inside the nozzle housings ensures protection during operation and prevents the ingress of contaminants. In front of and behind the nozzle housings are spacers (basket system) to prevent the nozzle tubes from hitting the well wall. In addition, for best cleaning results, the temperature of the medium should be between 3 and 30°C.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Optimum surface cleaning with KAMAT high-pressure rotating nozzles In order to ensure a surface treatment with excellent results and within a reasonable time, we have developed special externally driven rotating nozzles suitable for our high pressure pumps: Depending on the customer's requirements, our nozzles can be driven pneumatically, electrically or hydraulically. With traditional, self-powered rotating nozzles, the water jet hits an angle before it exits the nozzle, causing the nozzle to rotate. Driving the rotating nozzle causes the water jet to lose energy and is therefore much less efficient. Our externally driven rotary nozzles concentrate the hydraulic energy entirely on the machining process. KAMAT rotating nozzles provide coherent jets that can be moved precisely and quickly over large areas. In the case of externally driven rotation, the hydraulic energy is used entirely on the surface being sprayed, giving excellent and efficient results on surfaces.

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

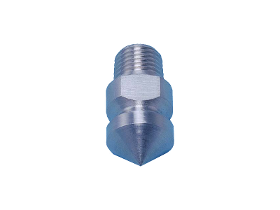

0.7mm 45° & 100° Fogging Angle 70bar (1015psi) 240gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.7mm 45° & 100° Fogging Angle 70bar (1015psi) 240gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.7mm 45° & 100° Fogging Angle 70bar (1015psi) 240gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.6mm 45° & 100° Fogging Angle 70bar (1015psi) 210gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.6mm 45° & 100° Fogging Angle 70bar (1015psi) 210gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.6mm 45° & 100° Fogging Angle 70bar (1015psi) 210gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.5mm 45° & 100° Fogging Angle 70bar (1015psi) 190gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.5mm 45° & 100° Fogging Angle 70bar (1015psi) 190gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.4mm 45° & 100° Fogging Angle 70bar (1015psi) 150gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.4mm 45° & 100° Fogging Angle 70bar (1015psi) 150gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.4mm 45° & 100° Fogging Angle 70bar (1015psi) 150gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.3mm 45° & 100° Fogging Angle 70bar (1015psi) 105gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.3mm 45° & 100° Fogging Angle 70bar (1015psi) 105gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.3mm 45° & 100° Fogging Angle 70bar (1015psi) 105gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.2mm 45° & 100° Fogging Angle 70bar (1015psi) 75gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TARHAN AUTOMATION AND MACHINE

Turkey

0.2mm 45° & 100° Fogging Angle 70bar (1015psi) 75gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

0.5mm 45° & 100° Fogging Angle 70bar (1015psi) 190gr/min Drip Safety System (Anti-Dirp) Stainless 303 (1.4305)

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Precision Machined Components manufactured by CNC turning Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China CNC Turning Factory, Custom hose nozzles from stainless steel, carbon steel with zinc plated, chromed, PVD coating, aluminum alloy, brass.

Request for a quote

PLANSEE SE

Austria

Nozzle tips for hot runner nozzles made of titanium-zirconium-molybdenum offer particularly high thermal conductivity of 140 W/mK coupled with excellent temperature and corrosion resistance. Glass fiber-reinforced plastics are exceptionally strong during processing but also highly abrasive. An optimum combination of thermal conductivity and material hardness is required. The TZM nozzle tips of Plansee are exceptionally resistant to aggression: the SHN surface hardening process. Using SHN surface hardening, we can strengthen peripheral areas and entire TZM components through the addition of a permanent, adherent diffusion layer. As a result, our customers benefit from the use of a tough, heat-resistant material with a wear-resistant surface. Surface hardening takes place during the gas phase. Coatings that we produce using the SHN process adhere better than conventional PVD or CVD layers. They perfectly replicate the surface contour of the TZM product.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Stable spray pattern under low pressures owing to the involute vortex chamber design. Made of highly wear-resistant SiC (silicon nitride bonded silicon carbide). Lightweight as made in all SiC (less than half of metal nozzle). Applications Absorption tower of flue gas desulfurization equipment Spraying slurry

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round impact area and uniform distribution. Spray capacity ranges from small to medium. X-shaped whirler provides large free passage diameter for minimal clogging. Applications Cleaning: Gas, incinerator fumes, machinery, eliminators, screen, tanks, parts, crushed stones, earth and sand, PCB, others Cooling: Gas, machineries, tanks, steels Spraying: Waste water treatment, aeration, foam breaking, fire extinguishing, dust suppression, sea water desalination, etching, chemical treatment

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round impact area and uniform distribution. Quick-detachable design helps to greatly reduce maintenance time. Whirler inside a nozzle is removable. Easy mounting/dismounting with a knurled tab. No falling off of tip or packing when removing the nozzle part. [INJJX series (plastic)] Made of high chemical and heat resistant PP (polypropylene). Nozzle tips are color-coded by spray capacity for easy identification. Applications [INJJX series (plastic)] Cleaning Etching Stripping For the applications where precise spray alignment and/or periodic maintenance is required

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round impact area and uniform distribution. Features smallest spray capacity among full cone spray nozzles. Unique design developed from new engineering concept to produce fine atomization by impinging two inflows inside vortex chamber. Ceramic orifice and closer provide excellent wear-resistance. Applications Spraying: Oils, lubricants, glues, etchants Cleaning: Galvanizing, gas Cooling: Machinery, gas

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Self-cleaning nozzle header. Inner brushes for nozzle cleaning are built-in. By rotating inner brushes, nozzle orifices are cleaned thoroughly, and foreign objects inside the pipe are flushed out through the drain. Available in the manual brush-cleaning type (the inner brushes are rotated by turning handwheel) and air-driven automatic type (which allows remote control of spray and cleaning modes). *1) Spray capacity per one nozzle (not per header). Applications [Steelmaking] In Continuous Galvanizing Line (CGL), Electrolytic Galvanizing Line (EGL), Continuous Pickling Line (CPL), and Continuous Annealing Line (CAL)

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Taking in surrounding liquid, EJX series solution agitation nozzle spouts out 3-4 times more volume than the amount supplied. Simple structure and compact design suitable for multiple-nozzle arrangement. Applications Solution agitation, preventing deposition, uniformizing concentration and pH Cleaning in liquids Submerged etching Plating

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Cleaning inside pipes and tubes, moving itself by means of spraying solid stream jets in different directions as driving force. High impact jets effectively remove scale and dirt inside pipes. Applications Cleaning: Pipes, drains, water and wastewater pipes, tubes of heat exchangers and cooling machines Others: Removing scale and rust

Request for a quoteResults for

Nozzles - ferrous metal - Import exportNumber of results

107 ProductsCountries

Company type

Category

- Nozzles - ferrous metal (56)

- Nozzles - non-ferrous metal (34)

- Bars - non-ferrous metal (8)

- Expansion joints - ferrous metal (5)

- Bars - ferrous metal (4)

- Pipe and tube fittings - ferrous metal (4)

- Pipe and tube fittings - non-ferrous metal (4)

- Expansion joints - non-ferrous metal (3)

- Profiled sheets - ferrous metal (2)

- Treatment of industrial waste water (2)

- Aluminium wires and cables (1)

- Cars, used (1)

- Cladding - ferrous metal (1)

- Gas and oil pipelines - installations (1)

- Industrial piping (1)

- Lubricants, industrial (1)

- Pipes and tubes - ferrous metal (1)

- Pipes and tubes - non-ferrous metal (1)

- Pipes and tubes, stainless steel (1)

- Rails - non-ferrous metal (1)