- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- orifice plates

Results for

Orifice plates - Import export

DELTAFLUID

France

Orifice plates or diaphragms are the most commonly used primary elements for differential pressure flow measurement. They allow measurement over a wide range of flow rates and for a wide range of pipe diameters. There are several types: the sharp-edge orifice plate, the best known, the other concentric plates with conical inlet and quarter circle plate for the measurement of low flows or viscous fluids and the eccentric plate or segmental plate for the measuring dirty or impure fluids. Finally, the multi-hole / conditioning orifice plate allows a measure of quality while providing a minimum footprint. Inserted within a circular pipe, they create an obstacle, increase the speed of the fluid and generate a pressure difference between upstream and downstream of the restriction. This differential pressure measurement is proprotional to the flow rate value.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Orifice plate is installed on pipe line to ensure evolution of fluid cross flow section (by 1 orifice) in order to create calibrated differential pressure loss. The measurement of if by 1 or x pressure taps pair(s) allow to define fluid flow rate. Process norm: NF EN ISO 5167-2, ASME MFC-14M, ASME MFC-3M, ASME PTC 19.5 Construction code: NF EN 13480, RCC-M, ASME, CODETI SPM capability: DN15 to DN1000

Request for a quote

DELTAFLUID

France

Recommended for low flow rates and / or viscous fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended orifice plate for dirty, charged or two-phase fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended for dirty, charged or diphasic fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended for viscous fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Economical solution thanks to the reduction of upstream and downstream straight lengthsStandard: Element designed on the basis of ISO 5167-1 & ISO 5167-2 or ASME FC-3M. Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application

Request for a quote

DELTAFLUID

France

Orifices: dimensioned according to the fluid, the pressure drop or the flow to be achieved going through the restriction. Plate thickness: calculated taking into account the pressure drop generated by the plate and the diameter of the pipework in order to avoid a deformation of the plate. For more details, see our Frequently Asked Questions. Noise: the number of orifices is determined according to the level of noise not to be exceeded. The maximum noise level depends on the operating conditions: limited to 85 dB(A) by the regulatory body for an average daily exposure in continuous operation. Intermittent or emergency operation - acceptable upper values (see corresponding regulations). If the noise level is still too high, it is possible to switch to a multi-stage restriction orifice. Cavitation: the cavitation level is checked for each plate and the orifices are calculated to avoid cavitation. For more information on cavitation, see our Frequently Asked Questions.

Request for a quote

DELTAFLUID

France

Complete measuring element with special flanges - Suitable for pipe diameters ≤ 40 mmInstallation of the integrated sharp-edge orifice plate: between special flanges (direct mounting of the manifold and the differential pressure transmitter) Solder (BW) or flanged connection Material: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Differential pressure flowmeter with upstream pressure tap located at a distance of D from the upstream face of the orifice plate and downstream pressure tap located at a distance of 0.5D from the upstream face of the orifice plate.

Request for a quote

DELTAFLUID

France

According to ISO 5167, flowmeters with orifice plates and nozzles (long radius) can benefit from D - D/2 mounting. This corresponds to a positioning of the upstream tap at a distance of 1D (D, internal diameter of the pipework) from the upstream of the orifice plate and the downstream tap at a distance of 1/2D from the downstream of the plate. This type of assembly has the advantage of not requiring orifice flanges (more expensive than standard flanges): you simply prepare bosses on the piping upstream and downstream of the measurement to position the pressure taps. It is widely used for large pipe diameters.

Request for a quote

DELTAFLUID

France

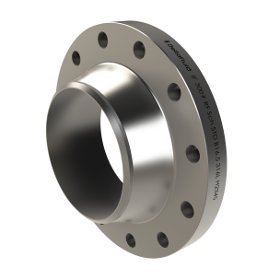

The 1''/1'' flowmeter is also called a flowmeter with flange pressure taps. The high pressure upstream measurement is 1 inch from the upstream edge of the plate and, symmetrically, the low pressure measurement is 1 inch from the downstream edge of the plate. This is often a pre-assembled complete set with orifice plate mounted between orifice flanges. Orifice flanges are standardized and manufactured to ASME B16.36. The orifice plate is manufactured in accordance with ISO 5167 or ASME MFC-3M.

Request for a quote

DELTAFLUID

France

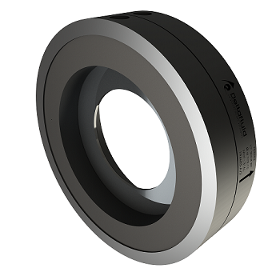

The annular chamber (carrier rings) is proposed for orifice plates, for venturis and for nozzles. It has several advantages: it favors the circulation of the fluid over the complete circumference of the pipework and offers a more stable and precise averaged pressure; in the case of the orifice plate, it also allows to change only the plate in case of maintenance or change of process compared to a monoblock where the complete system must be changed. This type of mounting is particularly recommended for pipe diameters smaller than DN50.

Request for a quote

DELTAFLUID

France

The flanges on the measuring elements and the piping allow easy assembly and disassembly unlike the welded assembly. Different types of flanges are available to meet all standards, all requirements in all areas of activity. Orifice flanges : They are used for flow measurement with orifice plates. They allow, thanks to the integrated pressure taps, to recover high and low pressure (Δp).

Request for a quote

DELTAFLUID

France

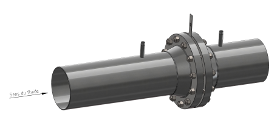

Complete and flexible measuring element to facilitate on-site installationMounting of the primary element between flanges: ISO PN 2.5 to PN 420, ASME 150 # to 2500 #, others on consultation. Solder (BW) or flanged connection Material: Standard: carbon steel, stainless steel, others according to your application.THE FLOWMETER INCLUDES: the desired orifice (orifice plate, nozzle) the flanges to fix the orifice upstream and downstream straight lengths in accordance with the chosen standard ASSEMBLY AND ASSEMBLY DATA: The design, manufacture and assembly are carried out in our workshops in compliance with the standards (upstream and downstream pipe roughness, centering of the primary element, circularity of the piping, upstream and downstream straight lengths) in order to achieve optimal measurement accuracy. CHARACTERISTICS : orifice plate - see corresponding technical data sheet nozzle - see corresponding technical data sheet upstream, downtrseam straight lengths

Request for a quote

DELTAFLUID

France

the desired orifice (orifice plate, nozzle) the flanges to fix the orifice the pressure taps (at the flange or in the corners, depending on the primary element chosen) and the impulse tubes integrated or remote 3 or 5 way manifold the preset differential pressure transmitter the built-in temperature sensor (for temperature compensation) in option MOUNTING AND ASSEMBLY DATA: Optimized centering of the measuring element Honing of upstream and downstream pipes to meet roughness criteria Temperature and pressure compensation for gases to achieve very accurate flow measurement Remote mounting of the instrumentation according to the applications CHARACTERISTICS : For orifice plates: see corresponding technical data sheet For nozzles: see corresponding technical data sheet Straight lengths upstream, downstream, roughness and circularity of the tubes, centering measuring element: see details on the FAQ tab on this page ACCESSORIES : Temperature sensor: Sensor mounted on downstream

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KROHNE MESSTECHNIK GMBH

Germany

The OPTIBAR DP 7060 is a differential pressure transmitter with integrated absolute pressure measurement. It offers a high degree of modularity for various flow, hydrostatic level or process pressure applications. For DP flow measurements it can be perfectly combined with the KROHNE primary elements (e.g. orifice plates or pitot tubes). Featuring a quick response time of just 125 ms, the DP transmitter offers high accuracy and measurement stability under all process conditions. KROHNE is the only manufacturer of process instrumentation to carry out a total 3D linearization of its differential pressure transmitter. For a robust and accurate differential pressure measurement, even under changing process conditions, each OPTIBAR DP 7060 differential pressure transmitter is linearized in all three dimensions during calibration: differential pressure, ambient temperature and static pressure are taken into account in combination.

Request for a quote

TURKOGLU

Turkey

Fire Sprinklers * PENDENT TYPE SPRINKLERS / UPRIGHT TYPE SPRINKLERS / SIDEWALL TYPE SPRINKLERS / SQUARE COVER PLATE ** Materials: Brass / Orifice: K80(5,6), K115(8,0) / Response : Standard and Ouick / Activation Temp.: 57ºC , 68ºC, 79ºC, 93ºC, 141ºC / Connection Dia.: 1/2'', Working Pressure: 175 PSI (12,1 Bar), Connection Type: Thread (NPT) *** Application Areas: Residences / Hotels / Hospitals / Business Centers / Hostel / Shopping Centers / Parking Areas / Garages / Factories / Storages etc.

Request for a quoteResults for

Orifice plates - Import exportNumber of results

21 ProductsCountries

Company type