- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal sheets

Results for

Metal sheets - Import export

ELEKTRON SP. Z O.O.

Poland

“Bending” is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in plastic materials, most commonly sheet metal. Commonly used equipment includes box and cup brakes, press brakes, and other specialised machine presses. Typical products that are produced in this way are boxes, such as electrical enclosures and rectangular ducts. Bending sheet steel The combination of modern presses, advanced matrix, stamps and the experience of our employees provides excellent results in the form of professionally performed artistic processing of various sheets. We bend sheets quickly and extremely precisely, and thanks to the fact that the process is fully repeatable and automatic, we can undertake even very large orders. The maximum pressure of our machines is as much as 200 tons, thanks to which we can undertake artistic processing of materials with a thickness of 6 mm over a length of 3 meters.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our specialized team enables us to carry out virtually any task related to the rolling of metal sheets up to 3000 mm in length and up to 25 mm in thickness. For complex shapes, we use micro-joints at key locations, and they will be removed after the process is complete. By bending the ends of parts, we eliminate the need for runouts, which translates into significant material savings. We roll rolls, ovals and cones, but we are also ready to meet the special requests of our customers. We have modern machinery, which guarantees precise execution of each order. We always meet the agreed deadlines, working efficiently and effectively. We offer customers a comprehensive service, which also includes sheet metal cutting service.

Request for a quote

ESTIMET SP Z O.O.

Poland

We provide sheet metal bending services using three precision Trumpf press brakes (TruBend_3100, TruBend_5085; TruBend_5320) with a maximum pressure of 320 tons and a maximum bending length of 4000 mm. Our well-equipped inventory of bending tools enables us to manufacture even the most complex parts, and dedicated software supporting machine operation allows us to simulate the bending process. All this guarantees the execution of orders with extreme precision and accuracy. In addition, in our machine park we have two CNC bending machines for bending pipes and profiles. We operate on both mandrel and mandrelless benders, while specializing in bending pipes and profiles. In our plant we deal with bending of, among other things: - structural steel - galvanized steel - stainless steel - aluminum

Request for a quote

CMPLAST

Poland

We produce guides of plastic with high resistance to abrasion. Our offer includes Guides the roller chains Guides the link chains Guides the belts Guides type of PZJ type of PZT ( TAB) type of PZTK (TAB K) type of PPTK (TAB K) type of PPJ type of PPT ( TAB)

Request for a quote

ESTIMET SP Z O.O.

Poland

We are offering CNC laser cutting from alluminium. On the picture: alluminum - 15 mm. Our CNC controlled lasers with a power of up to 6 kW work 24 hours a day. We carry out services on our own or on customers’s material. We cut the whole range of various types of materials. Services are performed on cutting-edge machines with a working area of 4000 x 2000 mm and a cutting thickness of 25 mm. Laser cutting is becoming more popular as one on main methods of steel cutting. This is due to high precision, outstanding quality and amazing speed of cutting. Laser cutting technology easily cuts steel and other materials with a precision that is out of reach of other technologies. ESTIMET offers laser cutting services for companies from many different industries across Europe. We carry out orders involving series of many thousands of elements; we also produce single elements we the needs of prototypes. Our factory has been created specifically for the needs of sheet metal processing services.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our services include water sheet metal cutting. The parts we cut comply with the EN 1090 standard, and therefore with the CE mark. We use the waterjet cutting method for various types of parts whose dimensions do not exceed 2000 x 4000 m and whose thickness is up to 200 mm. We cut with a stream of water with an admixture of abrasive at a pressure of 60,000 PSI, without introducing heat into the material, so we can cut in addition to steel materials: - stone - marble - plastic - rubber - glass The WaterJet method, or waterjet sheet metal cutting, involves the use of a jet of water at very high pressure - often supplemented by the addition of an abrasive. The jet is directed at the surface to be processed, which makes it possible to cut a shape in it with the desired dimensions. Modern WaterJet technology is an attractive alternative to plasma or laser cutting.

Request for a quote

ESTIMET SP Z O.O.

Poland

One of the areas of ESTIMET's offer is laser cutting, used for precision processing of sheet metal, pipes and profiles. In ESTIMET's machine park we have two fiber lasers of 6 kW and 8 kW. Thanks to these devices, we can precisely cut elements with maximum dimensions of 2000 x 4000 mm. Our laser cutting services comply with the EN 1090 standard, as confirmed by the CE mark. We are ready to take on even the most demanding orders, offering to cut sheet metal made of a variety of materials, such as carbon steel, stainless steel, aluminum, copper or bronze. We also have a gas burning machine, dedicated to metal sheets up to 150 mm thick. In addition, we have specialized machines for cutting pipes, profiles and sections with maximum dimensions of 450 x 450 mm. We can cut tubes and profiles in straight sections as well as at an angle. The range: steel: 0,5 - 25 mm INOX: 0,5 - 30 mm aluminum: 0,5 - 25 mm brass: 0.5 - 10 mm copper: 0.5 - 10 mm galvanized: 0.5 - 4 mm

Request for a quote

ESTIMET SP Z O.O.

Poland

Metal plate CNC controlled gas cutting up to 6000 mm x 2000 mm, thickness of 150 mm We have over 30 years of experience in metal plategas cutting . Today, CNC controlled gas cutting is a very effective and economical method of cutting metal plate. Thanks to several cutting heads, we are able to guarantee a large quantity of finished products in a short time. Despite major progress in the development of other cutting methods (laser cutting, water jet cutting or plasma cutting), gas cutting continues to enjoy great popularity. It is a relatively slow method, but with the right technological approach it guarantees high efficiency of production at a very low cost of finished elements. Gas cutting has no competition in terms of cutting sheets of more than 60 mm. The only technology that can be used instead is water jet cutting, but gas cutting is by far cheaper.

Request for a quote

ESTIMET SP Z O.O.

Poland

Often used as an alternative to gas cutting, plasma cutting is a reliable method of cutting sheets of blackplate, stainless steel and aluminum up to a thickness of 40 mm. Our machine allows sheets with dimensions of 6000 mm x 2000 mm to be cut. Plasma cutting is one of the most popular steel sheet cutting methods. It is especially appreciated in the case of cutting thick sheets of aluminum or stainless steel. The large working area makes this method unbeatable by technologies such as laser cutting or water jet cutting. ESTIMET offers plasma cutting services for companies from many different industries across Europe. We carry out orders involving series of many thousands of elements, we also produce single elements we the needs of prototypes. Our factory has been created specifically for the needs of sheet metal processing services. Thanks to automation, as well as our committed staff, production is carried out 24 hours a day.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide sheet metal bending services. Our sheet bending is carried out with the help of edge presses with very high accuracy, long-series elements can be implemented through an automated device that supports the work of qualified operators. Material possibilities: • we have three press brakes that enable sheet bending at a length of 3000 mm. • The maximum bending length is 3000 mm • The maximum thickness of bending over a length of 1000mm – 5mm and 8mm • Pressure – 125 and 135 tons • With Laser head for cutting material at an angle – 3D Please send your inquiry to the following e-mail address: biuro@web-elektron.pl

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide laser cutting services for stainless steel, black steel, and aluminum sheets. We cut details both from our own material and from the material supplied by our customers. Maximum thickness of cut sheets: • Black steel – 12, 25 mm • Stainless steel – 6,15 mm • Aluminum – 6,10 mm • Brass – 4 mm • Copper – 3 mm • Maximum working area 3000 x 1500 mm Please send your inquiry to the following e-mail address: laser@web-elektron.pl

Request for a quote

FORM CREATIONS

Poland

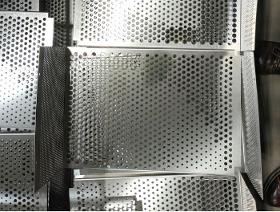

Classic Battery and Accessories Display This functional metal display for batteries and small accessories is an ideal solution for stores, wholesalers, and other retail outlets. The rack is made of perforated sheet metal and a solid metal construction. The perforation of the sheet metal allows for precise adjustment of the hook layout to the size of the products. This allows you to create a clear and attractive display that will easily grab the attention of customers. The hooks on the display can be customized to meet the individual needs of the customer. Single, double, reach-out, and hooks of any length are available. The display has detachable legs/base, which makes it easy to store and transport. It can be easily folded.

Request for a quote

VOSSE SP. Z O.O.

Poland

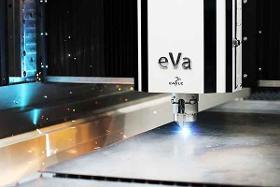

An extensive and versatile machine park is one of the fundamental development goals of the Vosse company. Another big investment in its implementation is the Eagle laser. Eagle eVision 1530 laser cutter with 6000W power 1. The size of the processed sheet 1500x3000 mm 2. Max. Weight of the processed material 900 kg 3. Positioning speed - X-axis 150m / min 4. Positioning speed - Y-axis 150m / min 5. Positioning speed - Z-axis 150m / min 6. Max. Cutting speed 150 m / min 7. Acceleration for X and Y axes 3 m / s2 8. Cutting accuracy (for 1 mm sheet) + -0.1 mm CNC control - Beckhoff TwinCAT CNC Positioning accuracy + - 0.05 mm Maximum thickness of the sheet metal blank Structural steel 25mm 25mm stainless steel Aluminum 20mm Copper 12mm Brass 15mm In addition, we also have the option of cutting on an Eagle laser the size of a 4x2m work table.

Request for a quote

VOSSE SP. Z O.O.

Poland

Light steel construction of hall.

Request for a quote

FORM CREATIONS

Poland

Adjustable shelving display for medicines and supplements is an ideal solution for pharmacies, gas stations, shops and gyms. Solid metal construction, powder coating and simple design make the shelf not only stable but also functional and attractive. Metal shelves are adjustable in height, so you can easily change the spacing between them to accommodate different sizes of products. At the top of the shelf, there is a panel with interchangeable graphics, where you can place the pharmacy logo, manufacturer or product information. The shelf is delivered fully assembled and ready to use, or flat packed in a carton for self-assembly.

Request for a quote

FORM CREATIONS

Poland

A gravitational can dispenser is a stylish and practical way to display your food products in your establishment. Made of high-quality materials, including wire and sheet metal, it is durable and resistant to damage. It takes up very little space on the counter. Its interesting, eye-catching shape allows for the free, gravitational fall of cans, and there is a place for graphics in the upper part, which can be used to promote your products. The dispenser is ready to use immediately after being taken out of the packaging. It does not require assembly or installation of additional elements. Simply fill it with cans and place it in the desired location. The dispenser is ideal for use in stores, pubs, restaurants, and gas stations. It is universal and can be used to display any type of canned beverage, both standard and slim.

Request for a quote

ADMET SP. Z O. O.

Poland

We offer sheet metal bending for all kinds of materials. Maximum width: 3000 mm Maximum thickness: 6mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TARET

Poland

We bend metal sheets on numerically controlled (CNC) bending machines from AMADA, LVD, PROMECAN, DURMA. In addition to bending sheets in a straight line, we also perform profiling on cylinders and bending pipes and profiles. We have 9 CNC press brakes, on which we can bend elements up to a length of 4 meters. Our largest press has 4 meters of working length and 320 tons of pressure. In the near future, our machine park will be enriched with a robotic station for bending sheets with an Amada press with a length of 4 meters and a pressure of 220 tons.

Request for a quote

MARXAM PROJECT

Poland

CNC bending of sheet metal technology is the most popular method of plastic processing, allowing to obtain details of both simple and complex shapes. The use of modern press brakes allows for the maximum possible repeatability in cnc bending of the produced elements for any number of items. The modern CNC tube bending services and the automatic compensation of the deflection arrow give maximum accuracy and repeatability in 7 axes and allow you to maintain the required angles along the entire length of the bending line. An extensive tool park allows us to adapt to any customer’s technological requirements. We offer sheet metal bending services, such as tube bending, metal curving, metal sheet folding, aluminum sheet bending, bending steel and many more.

Request for a quote

MARXAM PROJECT

Poland

Laser cut companies have become quite prominent in metalworking industries. Choosing Marxam Project, you are choosing a reliable partner with decades of experience. Sheet metal laser cutting is a technology that allows you to quickly and cheaply obtain an element of any complex shape from various types of flat sheets. The undoubted advantages of laser cutting are: - cutting laser offers freedom of shapes, limited only by the properties of a material; - cutting metal with repeatability of details at the level of 100%; - for given types of materials and their thickness, the laser cut surface is of a quality that allows the elimination of the finishing process; - the best possible use of the surface of the material – thanks to the use of appropriate computer programs, with our laser cutting services, we obtain a large percentage of sheet metal use, and we can properly optimize the production process; - it allows to reduce the effect of heat on the deformation of the cut material

Request for a quoteResults for

Metal sheets - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Cutting - steels and metals (7)

- Bending - steels and metals (5)

- Industrial sheet metal work (3)

- Laser - cutting and welding machines (2)

- Profiled sheets - ferrous metal (1)

- Punching machine tools (1)

- Metal construction, lightweight (1)

- Compactors and crushers (1)

- Display units for shops (1)

- POS - fairs and exhibitions (1)

- POS - stores and supermarkets (1)

- Pharmacy fittings (1)