- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- structural work

Results for

Structural work - Import export

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

https://www.europontex.com/wesell.html

Request for a quote

COMPANY TOR

Russia

The inverter machine VIKING 500A PRO is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of VIKING 500A PRO devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 500А (100% at 420 A). The welding inverter machine can be used at low temperatures and reduced supply voltage. Adjustable functions of hot start and arc reheat imply the ability to adjust the operation of the device with minimal spattering and allow you to perform work in any spatial position of the electrode and welded surfaces.

Request for a quote

COMPANY TOR

Russia

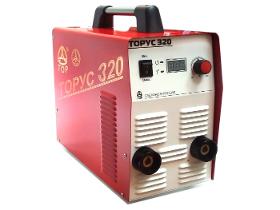

The Russian-manufactured inverter machine ТОРУС-320 is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The metal housing is equipped with large ventilation holes in order to prevent overheating of internal components. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of ТОРУС-320 devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 320A (100% at 300A). The welding inverter machine can be used at low temperatures and reduced supply voltage.

Request for a quote

DE SMET ENGINEERS & CONTRACTORS

Belgium

Thanks to its own sugar know-how, DSEC specialized in sugar plants EPC construction. The company acquired its expertise through the realization of many projects, ranging from audits of existing installations up to the turnkey construction of new industrial complexes. As for its other activities, DSEC is able to execute sugar related projects under the form of full EPC contracts, being familiar with all aspects of the project's implementation. DSEC not only masters specific sugar techniques and technologies but also all related process auxiliaries, civil works, steel structures, installation works, start-up and commissioning activities, including training of the client's personnel. DSEC’s project design and construction management gives paramount importance to the respect of health and safety and environment norms as well as to technical efficiency and ease of operation. The monitoring of project cost, time schedule and performances is the essence of any EPCM or EPC commitment. DSEC has developed proprietary technological and thermodynamic programs that very accurately simulate the operation of plants, from overall Heat & Mass Balances down to unitary process operations. In terms of drawings, DSEC uses a powerful 3D drawing and construction management tool (SmartPlan®) that dramatically improves material purchasing activity and site installation efficiency through a high level of prefabrication works. The importance of cogeneration and energy saving concepts has deeply changed the design of sugar plants construction and refineries over the last thirty years. DSEC is particularly proud of the results obtained in plants that have been built or upgraded in accordance with its studies and recommendations. DSEC’s independence from equipment suppliers and technology providers allows selecting the best possible technical solutions with a view of optimizing performances, energy recovery, maintenance and cost to the benefit of any project. In addition to state-of-the-art projects, DSEC’s engineering skills combined with agro process know-how have been selected by major players for developing large scale industrial units from laboratory developments and pilot plants. The projected increase in world sugar demand of 100 million tons over the next 15 years makes De Smet Engineers & Contractor’s knowhow in sugar plants EPC construction extremely valuable for the market.

Request for a quote

LAIPTU KARALYSTE, UAB

Lithuania

Concrete staircase, manufactured by us, is the staircase, made on concrete structure. The staircase on concrete is the most stable, very strong structure. In-between steps and wooden stairsteps are attached to concrete structure by using the special glue. What is more, wall edgings and edgings from outside, under the stairsteps are often installed, in order to cover the constructional defects (cracks). We do not cast any concrete structures – we only install the wooden parts of a staircase: stairsteps, in-between steps half-stairsteps, railings. As we do not cast any concrete structures, we often have to correct the discrepancies between the height and width of stairsteps, left by other builders. Unlike metal structure, which is installed within 1 day, preparation and casting works of concrete structure take some days. Then, this structure must dry for at least 3-4 months, in order the installed wooden stairsteps would not absorb the excess water, left in concrete. Otherwise,...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Structural work - Import exportNumber of results

5 ProductsCountries

Company type