- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotary transfer machines

Results for

Rotary transfer machines - Import export

IMOBERDORF AG

Switzerland

imo-space is Imoberdorf's biggest rotary transfer system in terms of productivity and functional possibilities. Designed on 6 to 20 machining stations with up to 45 or more spindles, the imo-space has enormous production potential. The imo-space provides you with a ready-to-use machining solution, tailored to your specific requirements and with an enormous range of applications. The parts feed is carried out from bar stock, by means of load handling, robot or using Pick & Place. At the same time, the reproducibility of ± 0.003 millimetres makes the imo-space one of the most precise rotary transfer machines in the world. The imo-space meets the highest demands for functionality and productivity. With this large platform, the possible applications are pushed to the extreme. The 3-axis E-88-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically

Request for a quote

IMOBERDORF AG

Switzerland

These days, more than ever, cars are technical masterpieces. To satisfy performance and safety requirements, all components right down to the smallest must be manufactured with extreme precision and in top quality. Imoberdorf rotary transfer machines let you produce car parts such as fork-type joints, injection components, gearbox parts and membranes for the park/distance sensor technology in high quantities and with maximum precision. Quality means safety.

Request for a quote

IMOBERDORF AG

Switzerland

Watch movements are among the most complex, most precise and most elaborate mechanical objects that can be produced. Since the development of the first rotary transfer machine for watch components in 1953, Imoberdorf has always pursued the goal of constructing systems that set new benchmarks with regard to productivity, flexibility and precision - and that are compact in construction and design at the same time. This enables boards, crowns and other watch parts to be manufactured with high precision, flexibility and in large quantities. Your quality standard is our trademark.

Request for a quote

ERLO GROUP

Turkey

Transfer machines allow to perform different machining processes of parts or components within the same solution. Our solutions can be designed according to customer demands enabling processes such as drilling, turning, milling, tapping, countersinking, internal and external grooving and reaming among many for more than one product on a single CNC machine.

Request for a quote

HOCHRAINER GMBH

Germany

Different systems can achieve the objective depending on product requirements: Machine tools for type VSMH rotary transfer machining (hydraulic) Machine tool for type VSMK rotary transfer machining (cam-controlled) Type NBM finishing machines for stamped, moulded, and cold extruded parts Our years of experience in complete machining of serial parts passes to the next generation in constructive and innovative cooperation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IMOBERDORF AG

Switzerland

On an area of only 9 square metres at a height of 2.30 metres, the imo-compact unites to form a complete, highly-productive rotary transfer system: The imo-compact controls 4 to 8 machining stations with up to 14 spindles per CNC. The parts feed is carried out optionally from bar stock, by means of load handling, robot or manually. The reproducibility of ± 0.003 millimetres makes the imo-compact one of the most precise rotary transfer machines in the world. The imo-compact unites all the elements of a rotary transfer machine. Even the smallest platform offers optimum accessibility. The 3-axis E-97-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-smart and the imo-space The imo-rot corresponds to the 4th axis: the C-axis

Request for a quote

IMOBERDORF AG

Switzerland

The imo-smart is a highly-flexible, versatile rotary transfer system. 4 to 16 machining stations with up to 22 or more spindles ensure fastest setup times. The imo-smart provides you with a ready-to-use machining solution, tailored to your specific requirements and with a wide range of applications. The parts feed is carried out from bar stock, by means of load handling, robot or manually. With a reproducibility of ± 0.003 millimetres, the imo-smart is one of the most precise rotary transfer machines in the world. The imo-smart is designed to be a highly flexible and versatile solution. The excellent accessibility allows adjustments to be made in record time. The 3-axis E-80-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-compact and the imo-space

Request for a quote

ABF LT

Lithuania

We are able to offer aluminium die casting services in Lithuania using automated die casting machines from 350 to 850 tons. Supported by CNC milling and rotary transfer machining, we can provide semi finished product for your company's' project.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With the new generation of our combination machines, we have continued to develop the new diversity for forming pipes. Geometries that effectively replace high-cost and expensive turned parts can be formed directly at the pipe end in the endforming machine – for a final component of a single workpiece that is ready for use without elaborate soldering or welding. Implementation of the combination can be specified by you or based directly on the forming geometry. This is usually done using up to 6 axial forming stages and at least one rotary unit. Trimming, as well as axial and rotary forming, may require 2 rotary forming stations. Simple trimming or deburring after forming at the pipe end are no demanding challenges. Therefore, all our axial forming machines and combination machines are equipped with one or several single-drive axes. They have a servo-electrical drive and can be used in each of the holders for the forming stages, making the system is very flexible and compact.

Request for a quote

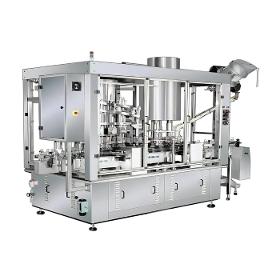

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

IMOBERDORF AG

Switzerland

Due to their flexible construction and virtually unlimited machining variants, Imoberdorf rotary transfer systems are suitable for the manufacture of the most diverse small and miniature parts. Please contact us − we are glad to help you identify the opportunities that will be opened up for you with an Imoberdorf rotary transfer system.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

This model is well suited for efficient, economical processing of circular workpieces via surface and step grinding operations. There is no lost time through deceleration, acceleration and reversal as with conventional reciprocation grinding. The grinding wheel remains in contact with the workpiece throughout the grinding process. Single workpieces can be located centrically on the table while multiple workpieces can be located concetrically to optimize table space utilization. A tilting table option allows grinding of chamfers or blade edges (i.e. circular blades), where the table can be tilted +/- 5 degrees. The high-precision rotary table is belt driven. This machine is offered with the xpressCube SPS controls package. A software option is available for step grinding operations. Benefit Overview — Compact and robust machine design — High productivity through continuous contact between wheel and workpiece — High long-term precision — Precision rotary table — Easy to operate

Request for a quoteResults for

Rotary transfer machines - Import exportNumber of results

13 ProductsCompany type