- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- saw frames

Results for

Saw frames - Import export

STANDART ALUMINIUM

Turkey

Our dynamic mechanical processing team with deep measurement precision and surface quality, precision single head, double head angled cutting saws, undercut saws, punch machines, solar frame machines, eccentric presses, hole drilling drills, tapping machines, CNC benches, perfect quality and offers superior service

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

To address the most stringent demands in terms of cutting output, high precision, automation and process reliability BEHRINGER HBM series high-performance automatic bandsawing machines offer an impressive package of benefits, guaranteed not only by their vibration-damping structure made of grey cast iron components and the saw frame with its centric flow of forces. The sensitive BEHRINGER feed control also helps protect the saw blade, ensuring even greater economy through a long tool service life. By using a servo feed system, a high cutting performance is achieved when sawing tool and stainless steels and materials such as Hastelloy or Inconel with difficult machining properties. A highly efficient chip brush system cleans the saw blade on both sides from any adhering sawing chips.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic mitre bandsaws from BEHRINGER are saws to really get things moving. Particularly when it comes to classical series production such as cutting to fixed lengths and mitre sawing in automatic mode. And also when cutting layers and packages they make a good impression. By their excellent cutting performance and short nonproductive times, your productivity can be increased significantly. Using an NC controlled feed gripper in conjunction with an NC controlled saw frame mitre box, fully automatic mitre cuts can be performed on both sides. The PC control system provided as standard makes for extremely simple menu-prompted operation of the saw and peripheral devices. The BEHRINGER mitre bandsaws contain many useful features already in the basic price: - Convenient PC control - Fast NC-controlled mitre system - Vertical clamping unit - NC-controlled feeding gripper with 3.000 mm feeding length in single stroke - Spray mist cooling system

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

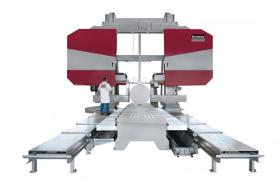

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The SLB bandsawing machines from BEHRINGER: A trustworthy partner for workshop and plants. Suitable for cutting tubes, profiles and solid materials made of metal and comparable plastics. Competitive pricing, precision made components, and impressive power. See for yourself. - Mitre cuts are possible from + 30° to – 45° - Scale for setting the exact angle — Clamping of the saw frame with a quickly-tension lever — Downfeed control by a hydraulic flow control valve - Automatic height-setting of the saw frame above the material — Frequency controlled sawblade drive (optional) — Exact cutting

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MASCOTT ARS LTD

Belarus

There is an angular disk frame-saw of MAA in-process. A sawing process is automated and produced by means of next equipment: •loading rack with transporter •angular disk machine-tool •conveyor for sawdust removal •operator's cabin •hydraulic flow of logs Advantages: •High productivity (15-25 m3, when shift work is 12 hours ) • imported components (Sati (Italy), Hidrocel (Turkey)) • Modular line design assumes possible modernization in the future; • High quality of the received material; • Using a hydraulic system, which allows you to: - Reduce the weight and dimensions of the equipment - The time for starting and accelerating the motor is a fraction of a second, which is unattainable for large electric motors (several kilowatts). - Frequent on-off, stop and reverse movements are not dangerous for the motor. -The law of movement of the shaft of the hydraulic motor can be easily changed by using the means of regulating the hydraulic drive.

Request for a quote

DISPA MACHINE

Turkey

• Semi-automatic double miter for cutting profiles and solid material in steel and non-ferrous material and an excellent price-performance ratio • Manually swiveling saw frame with hydraulic clamping for optimal • Hydraulic clamping of the horizontal vise • Automatic saw frame raising on the cut end • Double speed motor 1.0/1.3 KW Gearbox • Sensitive cutting pressure regulation function of the material properties • Hydraulic-mechanical belt tension • Tape guide with hard metal pads sheets and rolls • Thermal overload protection and no-volt release • Automatic shut-off after cut end • Automatic belt break protection Driven

Request for a quoteResults for

Saw frames - Import exportNumber of results

8 ProductsCountries

Company type