- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bulk material

Results for

Bulk material - Import export

TOMECH SOLUTIONS

Romania

Hoppers and transfer chutes are essential components of material handling systems, facilitating the smooth movement and transition of bulk materials within industrial processes. We specialize in hopper and chute design services, offering tailored solutions to optimize material flow, minimize downtime, and improve overall system performance. Our expertise encompasses the design, analysis, and optimization of hoppers and transfer chutes to meet the specific requirements of our clients and enhance the efficiency of their material handling operations.

Request for a quote

TOMECH SOLUTIONS

Romania

Bulk handling equipment encompasses a diverse range of machinery and systems designed to efficiently transport, store, and handle large quantities of bulk materials such as ores, minerals, grains, chemicals, and aggregates. These equipment play a vital role in industries such as mining, agriculture, construction, and manufacturing, facilitating the movement of materials along various stages of the supply chain. We specialize in the design, engineering, and integration of bulk handling equipment, offering customized solutions to optimize material handling efficiency, minimize downtime, and enhance overall operational performance for our clients across various industries.

Request for a quote

TOMECH SOLUTIONS

Romania

Screens play a crucial role in material handling and sorting processes by separating particles based on size, shape, and composition. They are commonly used in industries such as mining, construction, recycling, and agriculture to classify and sort bulk materials efficiently. Screens consist of a surface with apertures or perforations of varying sizes, through which material passes. As the material moves across the screen surface, particles smaller than the aperture size fall through, while larger particles are retained. Screens can be vibratory or stationary, depending on the application and required throughput. We specialize in screen design services, offering customized solutions to optimize screening efficiency, throughput, and product quality. Our expertise encompasses the design, selection of screen media, and configuration of screening equipment to meet the specific needs of our clients and enhance the performance of their material handling and sorting operations.

Request for a quote

TOMECH SOLUTIONS

Romania

Feeders are devices used to regulate and control the flow of bulk materials from a storage container or hopper to downstream processes or equipment. They play a vital role in ensuring a steady and controlled supply of material, enhancing the efficiency and productivity of material handling systems. Vibrating feeders are a type of feeder that utilizes vibrations to move materials along a trough or tube. Vibrating feeders are commonly used in industries such as mining, aggregate processing, and pharmaceuticals due to their ability to handle a wide range of materials and feed rates while minimizing spillage and dust emissions. We specialize in feeder design services, offering tailored solutions to optimize material flow, feed rate, and system performance. Our expertise encompasses the design, selection of feeder type, and integration of feeding equipment into material handling systems to meet the specific requirements of our clients and enhance their operational efficiency.

Request for a quote

TOMECH SOLUTIONS

Romania

We proudly offer specialized 3D CAD engineering services across diverse domains to meet the unique needs of our clients. In the realm of bulk material handling, we excel in creating precise and customized 3D models for conveyors, stackers, and reclaimers, optimizing material flow and system integration. Our expertise extends to recycling, where we design and model equipment such as conveyors, shredders, crushers, balers, and waste-to-energy plants, ensuring efficient and sustainable processes. Additionally, our capabilities extend to custom 3D works, allowing us to transform creative concepts into reality through digital modeling. Whether it involves unique product designs, artistic installations, or specialized components. Our commitment lies in delivering precise and efficient designs that cater to the specific requirements of each sector, ensuring that our clients receive tailored solutions that meet industry standards and regulatory compliance.

Request for a quote

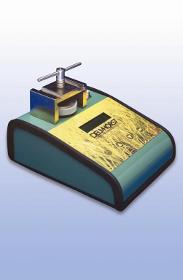

DELMHORST EUROPE

Netherlands

Moisture meter Name: Moisture meter for Grain, G-7 Material: Grains, Seeds, Hay, Pasta Mc: 9-30% Calibrations: Barley, Coffee, Corn, Flax, Hay, Oats, Pasta, Rapeseed, Rough rice, Rye, Sorghum, Soybeans, Wheat Overview The G-7 moisture analyzer is a rugged resistance-type meter, great for testing the moisture content of grain at harvest time and while in storage. The integral double-disc electrode cup holds only 3-4 grams, allowing for more uniform sampling and providing accurate and repeatable readings. You can even attach optional accessories to check moisture in bulk material and hay. The G-7 also provides useful statistics on stored readings. Your Benefits: Built-in calibrations for barley, coffee, corn, flax, hay, oats, pasta, rapeseed, rough rice, rye, sorghum, soybeans, and wheat Built-in temperature correction over the range of 0-70° C (32-160° F) Programmable offset to match elevator Stores up to 150 accumulated readings in user-defined batches by grain Displays the aver

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Mixing Bulk material processing with convincing results With our mixing systems homogeneous mixtures and coatings are produced from various bulk material. This is enabled by our cutting-edge mixing machinery which includes drum mixers, container mixers, Nauta Mixers, high-speed mixers, Rhönrad mixers, swivel screw mixers and other special mixing systems. Modern machinery guarantees quality The mixing machinery at Ebbecke is supplemented by a fully automatic gravimetric load cell weighing plant, as well as by a chopper, nozzle fittings and equipping possibilities for various containers. Technically, Ebbecke Verfahrenstechnik AG is thus equipped for every task imaginable in the area of contract mixing, even for contract mixing of particularly shear-sensitive bulk material. The quality of our mixing machinery proves itself in the technical details: Product-contacting parts consistently made of stainless steel in accordance with the current hygiene standards. Furthermore, all mixing sys

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Contaminated bulk material is cleaned One of the most annoying and expensive problems with bulk material processing is the contamination by foreign substances. These contaminants not only reduce the quality of the final product, they also cause damage to the machines and failures. Especially high-strength small metal parts such as screws, nuts, washers, or cotter pins cause serious damage to the processing machinery. For this reason, the production costs with contract processing are often uncontrollable. Ebbecke has the production under control To solve this costly nuisance, the engineers of Ebbecke Verfahrenstechnik AG have developed their own system with which goods that have been contaminated by metal particles can be cleaned. This is done using the inductively-working metal detector that detects even the finest metal abrasions and reliably separates them from the goods. Through a trouble-free production process delays, non-compliance of supply contracts and consequent compensatio

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Testing plants in the area of bulk material processing Innovations made by Ebbecke Verfahrenstechnik To create a product exactly according to the ideas of the customer, standardized procedures are sometimes not enough. That’s why customers come from all over Europe to Ebbecke Verfahrenstechnik AG in Central Hesse – because our engineers are prepared to develop entirely new process engineering methods. With the new and further development of procedures and machines we are at the same time opening up alternative business areas for our customers. Testing and development without financial risk With all technical developments, our engineers keep the efficiency of the processes in sight. Because one thing is clear: An innovation can only prevail on the market if the development and subsequent purchase price remain within defined economic boundaries. This is where Ebbecke Verfahrenstechnik AG has been impressing for years with its pilot plants as centers of in-house development work. Toget

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Screening The right screening procedure for any size and virtually any bulk material Ebbecke Verfahrenstechnik AG has the right plants and a know-how developed over decades for the best screening results with virtually any bulk material. For this reason, customers come to us for contract screening from the cosmetics, pharmaceutical, food, chemical and animal feed industries. Cutting-edge technology As a contract screening company active for many years we know what the priorities are for our customers. For these needs, we have self-developed our contract screening plants from Planoscreen and Planodry types. With these advanced contract screening plants not only can we screen contaminate-free , we can at the same time dry the screened product under a nitrogen atmosphere or a pressure cascade. In addition to the machines and process engineering plants that we have developed we also screen on systems from other manufacturers. For this completely different screening procedures are used d

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Dry micronization The optimal solution for fine grinding of bulk material We offer you a wide range of different types of plants for contract grinding in our fine grinding centers. Among them are special grinding plants, such as a special mill for natural products, an efficient circulating gas plant and a cryogenic grinding system for temperature-sensitive products. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Grain size exactly as you request it! Our fine grinding plants enable the dissolution of agglomerates as well as the breaking up of solid grain structures up to the finest grinding in a reproducible product quality. Customers of Ebbecke Verfahrenstechnik AG appreciate the flexibility of the available grinding systems that can be customized to suit the specific requirements of the grinding process. Nothing is left to chance because cutti

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Fine Mill The solution for fine grinding Ebbecke Verfahrenstechnik AG is your specialist for demanding tasks in the area of ??contract grinding. The fine grinding plants used enable the dissolution of agglomerates as well as the breaking up of solid grain structures including even the very finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Accordingly, they comply with all the strict specifications and hygiene standards of the of food, pharmaceuticals and cosmetics industries. Technical data Target fineness: 1.0-5,000 µm Plant types: Classifier mills, air jet grinding plants, spiral jet grinding plants, pin mills, cross beater mills, hammer mills, Fitzmill, screen mills, disc mills, graters, crushers, cryogenic grinding, nitrogen overlaid plants Product-contacting parts: Stainless steel Delivery in: Bags, bales, Big Bags, octa

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Co-packing customized to your requirements Our plants are ready for you – flexible and efficient! Co-Packing by Ebbecke Verfahrenstechnik Whether Big Bag, octabins, drums, fiber drums, bags, cardboard boxes, buckets, cans or special containers – we work exclusively and without exception with all containers that are used in the bulk material area. At Ebbecke Verfahrenstechnik AG this standard also applies for the size of the container. We process deliveries in silo vehicles, bulk containers and large containers just as efficiently as we fill small containers or containers with a low final weight. As contract compactors, we have been valued partner of the industry for many years. Filling – and much more With our modern machinery we are able to process virtually any bulk and free-flowing materials – whether viscous, pasty, floury, fine or coarse-grained. As reliable contract processors with a wide range of services we don't just fill, but we are ready for our customers as a fully-fle

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quote

CUCINA FINANCE LIMITED

United Kingdom

Cucina Finance (UK) Limited provides personal loans/business loans/trade finance/import & export loans/project loans to companies of all sizes ranging from individuals, companies and trader's globally. No jargon, no hidden fees Simple approval process Fast business loans funded in just 2-3 business days Low Interest rate of 2% Prior bankruptcies accepted Zero credit checks required CIS & KYC required for all loan applicant irrespective of location/country Loan Duration from 1 year - 20 years maximum Grace period of 12 - 24 months for large business loans/working capital Loan Funding/Financing is not limited to any geographical location or country whatsoever For further details, Kindly contact us via email, telephone, Skype. Intermediaries/Consultants/Brokers are welcome to bring their clients and are 100% protected. CUCINA FINANCE (UK) LIMITED https://cucinafinance.com Email: finance@cucinafinance.com Tel no: +44 (123) 388-5014 Whatsapp: +44 7425-381661

ROKAUTA, UAB

Lithuania

Bulk cargo transportation in dumpsters, oversized cargo transportation We currently offer over 10 heavy duty dumpsters for bulk cargo: + asphalt concrete; + gravel; + sand; + other bulk materials.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanShock® impact bars germanShock® IP impact bars replace conventional buffer rollers at in-feed and absorb the impact energy of dropping bulk material, thus reducing damage to the belt. Combination with our germanLine® skirting rubber provides effective side sealing at in-feed. ... more

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

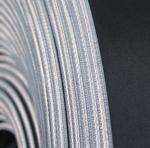

GERMANBELT SYSTEMS GMBH

Germany

Cleats with heights from 20 mm to up to 280 mm Corrugated Sidewall Conveyor Belts for Inclined Transport of Bulk Materials We produce cleats in 4 different designs: T, C or TC cleats as well as multi-part cleats. Our germanWell® cleats for corrugated sidewall conveyor belts are available in standard quality and in oil or grease resistant quality and with or without biased fabric. Please see our product brochure for more details on weights, dimensions and qualities.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanWell® Corrugated Sidewall Conveyor Belts for Inclined Transport of Bulk Materials We use self-produced sidewalls with profile heights from 40 mm to up to 300 mm. In combination with our cleats, which we also manufacture ourselves, we can design and produce the optimal corrugated sidewall belt whatever the individual case. Our germanWell® corrugated sidewalls for sidewall conveyor belts are available in standard quality and in oil or grease resistant quality and with or without biased fabric. Please see our product brochure for more details on the germanWell® corrugated sidewall conveyor belt product range.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanWell® Corrugated Sidewall Conveyor Belts for Inclined Transport of Bulk Materials In inclined transport with germanWell® corrugated sidewall conveyor belts we use laterally stable conveyor belts - the germanCross basic belts. This lateral stability makes it possible to change horizontal to vertical direction of travel to vertical and vice versa. Laterally stable germanCross basic belts are available with 1 or 2 transversely rigid breakers and in strengths from 315 N/mm to up to 6000 N/mm. Just as sidewalls and cleats, germanCross basic belts are also available in highly abrasion-resistant and oil-resistant versions. We meet the customer requirements for corrugated sidewall conveyor belts. Get in touch with us.

Request for a quote

SEŠLAR FRANCI S.P., SEFRATRANS

Slovenia

Transportation of all types of goods by classic towing trucks and tanks for bulk loads. Our main activity is the transport of bulk goods by vehicles silos in domestic traffice, transport register (LTL) and transport complete consignments (FTL) in domestic and international traffic. Our vehicles are also equipped with their own aggregate. We have very modern fleet - EURO6 environmmentally friwndly heavy goods vehicles with tracking devices. The fleet consists of 9 Volvo and DAF vehicles that meet the latest EURO 6 standards. We use Feldbinder silo semi-trailers (35 and 37 cubic meters) for transporting bulk cargo. For cargo transport, six Tautliner 13,6 semi-trailers with sliding roof, sliding side tarpaulin, lifting roof and extendable rear pillar and one Tautliner trailer with a recess for transporting reels.

Request for a quoteResults for

Bulk material - Import exportNumber of results

22 ProductsCompany type