- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- maintenance work

Results for

Maintenance work - Import export

REILING GMBH & CO. KG

Germany

COMMERCIAL VEHICLES, VEHICLE, TIPPER & CONTAINER CONSTRUCTION, MAINTENANCE As an authorized partner of Scania, Meiller, and Palfinger, we're your go-to for all service and maintenance work, as well as the development and construction of special vehicles. With extensive experience in waste disposal and recycling, we're well-equipped to deliver top-notch results using cutting-edge technology. Benefit from our expertise and explore the diverse opportunities. SPECIAL VEHICLE CONSTRUCTION: UNIQUE REQUIREMENTS - CUSTOM SOLUTIONS Our team of highly qualified professionals designs and builds special vehicles tailored to your needs. No challenge is too big for us, thanks to continuous training and vast experience, ensuring precise solutions. Professional execution and state-of-the-art technical equipment are our standards. Contact us today for more information and offers!

Request for a quote

LEAN REŠITVE

Slovenia

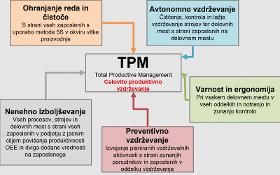

TPM method - comprehensive productive maintenance TPM method – Total productive maintenance or comprehensive productive maintenance is a method – project – mentality, which very intensively interferes with the habits and methods of work of both maintenance and production. A well-maintained fleet is the basis for high efficiency – productivity. The approach itself, the introduction of the method, depends on the correct strategy and setting up the organization TPM, which will take care of the gradual introduction of the method in the context of lean production. It is also crucial to choose the right TPM coordinator, who leads the internal project and takes care of the smooth work of all TPM teams. The responsibilities of the TPM coordinator depend on the size of the company and the intensity of the implementation itself. We can say that this is 1. method in efficient production.

Request for a quote

OPEN GRID EUROPE GMBH

Germany

Our services for mobile natural gas supply include the entire handling of the project, from receipt of your inquiry through preparation on-site, procurement and delivery of the gas to feed-in. We advise you on the optimum procedure, technical prerequisites and the necessary preparations on your part. Throughout all project phases, experienced staff are on hand to professionally manage and monitor the mobile supply, ensuring the highest degree of safety and efficiency. We can supply you with natural gas in the quality you require, e.g. For uninterrupted gas supply to your customers during maintenance work on your network For testing purposes in industrial companies considering switching to natural gas (e.g. in the steel, glass, porcelain and ceramics sectors) For testing purposes in plant sections where natural gas is not yet available For the initial fill and for purging of pipelines

Request for a quote

OPEN GRID EUROPE GMBH

Germany

The safe and efficient construction and operation of gas transmission systems calls for complex decisions; there are a number of prerequisites that must be met. This applies to many areas such as material selection, component design and sizing, well-founded assessments of the condition of pipelines and facilities based on various test procedures, the determination of the repair and maintenance work required as well as quality assurance for materials, procedures and personnel. We offer a comprehensive service portfolio in this area, based on the experience and know-how gained from the operation of our pipeline network and the technical infrastructure available for this purpose.

Request for a quote

OPEN GRID EUROPE GMBH

Germany

Maintenance and repair work on the natural gas network is generally carried out with the pipeline being gas-free, so the relevant pipe sections are isolated by installing valve assemblies and the gas in the isolated section is vented to atmosphere. By using our mobile compressors – individually or in highly efficient parallel operation – the network operator can transfer the gas from the isolated pipe section to another part of the system so it does not have to be vented to atmosphere. Connection points for the mobile compressors are available e.g. in the area of the main line valves or can generally be retrofitted. It makes economic sense to transfer the gas to another as this guarantees responsible handling of this primary energy source and makes a substantial contribution to protecting the environment. Services offered: Pipeline recompression until lowest residual pressure < 3bar Reduction of methane emissions by up to 95% Responsible handling with primary energy

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

Customer service and system maintenance – fast and future- oriented. Our goal is to create low- maintenance systems that guarantee maximum precision and maximum work capacities. Of course we also adapt our systems to satisfy our customers’ individual needs and to meet special requirements. We develop solutions to perfectly integrate our soldering systems into any given production process. At any time, STRECKFUSS SYSTEMS provides customers with spare parts, wearing parts, and alteration parts. We are a service team of experienced electrical engineers, mechanical engineers and system manufacturers. Beside the firm maintenance dates, our team is always available for short- notice duties. STRECKFUSS SYSTEMS guarantees an excellent customer service and takes on the responsibility for all system maintenance work with regard to both the new STRECKFUSS soldering systems and older models. Our customer service – an overview: commissioning briefing user training system inspection system maintenance system repair works on- call service system modification waste management

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Specification of Protec Kleen: Rubber linkages at sleeves, hood, legs and waist Cover above zipper up to chin green, outside lying overlock-stitch Cat. III Type 5 +6 Available sizes for Protec Kleen: L XL XXL Application examples: Disposal of toxic waste (landfill, asbestos-, building- and roof refurbishment Dealing with solids hazardous material (agriculture, livestock breeding Chemical industry (solids) Food industry Pharmaceutical industry Cleaning and maintenance working (canal-, tank cleaning and resin coating Police investigations

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Specifications: This breathable overall protects user in working area, where protection against powdered and pulverized substances, aerosols or mist is necessary. The ventilated back ensures comfortable working and high comfort. Besides, sensitive products and workflows at contamination are protected by the carrier. Protective clothing according to CE Category III, typ 5 + 6, anti-statics according to EN 1149-1 Application ranges: Asbestos, pharmacy, nuclear, varnish and coating, tank-, canal- and industrial cleaning, maintenance work, dealing with hazardous substance etc. Material: Microporous laminate layer Version: Integrated rubber linkages at sleeves, hood, legs and back. Heightened cover above zipper, inside lying stitches, 3-part hood Datenblatt

Request for a quote

ABFAD LTD

United Kingdom

Abfad Limited provide emergency rescue and safety cover for people working at height or within confined spaces, we provide these services to many different industries, including power generation, oil and gas and other onshore and offshore sectors. These services include: Confined Space Emergency Safety Cover for Power Station Boiler, Stacks, Turbines, etc. Tunnel Emergency Safety Cover supplying full BA services for clients personnel. Tanks, Vats, Silos, Vessels, Marine environments Safety Cover. Emergency Safety Cover for other trade personnel working at height and or any confined space working as above. Abfad’s rescue teams, are fully trained and equipped, so that should an emergency arise, they can perform the necessary assessment of the situation and conduct any rescue needed in a safe and controlled way. This ensures casualties are recovered in the fastest time possible and then administered with first aid.

Request for a quote

ABFAD LTD

United Kingdom

Abfad Ltd supply multi-discipline trade experienced rope access personnel for working at height in all industries where conventional access is impractical or simply not possible. IRATA approved rope access services such as inspection, repair/maintenance, blasting and coating, along with many other rope access services. Abfad Ltd supply rope access personnel with the ability to perform work to the required specification. Abfad’s safety supervisors are trained to the highest standards and will ensure risk assessments and method statements are provided and implemented for all work tasks. Abfad personnel work within Chemical Storage Depots, Power Stations, Refineries, Shipyards, Construction and heavy industry sites, Oil & Gas Upstream (Offshore) and Downstream (Fuel Forecourts), Wind Turbine and Renewable Energy Farms, etc. performing specialist high risk activities such as working at height and confined space storage tank protection.

Request for a quoteResults for

Maintenance work - Import exportNumber of results

11 ProductsCompany type