- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spot welding machines

Results for

Spot welding machines - Import export

ANKARA BRONZ

Turkey

ECU 99,9 % : Electrolytic is used as copper material with a conductivity of 58, electrode in erosion, high-low current panel and busbar in substations. Among our standard products: Rod, Sheet Plate, Straight pipe, Tube Coil, Box profile, Grounding rod - plate, Roofing, Copper fittings and thin wires. Also, sheet plate measurements which do not have a standard are brought to necessary measurement by forging at desired dimensions. Parts that require CU-Cr-Zr (Chromium alloy) High electricity conductivity, hardness and strength at high temperatures: Are used as point welding electrode and seam welding disc at the source of low carbon steels (Panel radiator, Gasoline warehouse, etc.) and Galvanized steel plate (Automotive and white goods), electrode holder at spot welding machines, plunger electrode at erosion machines and contact busbar at substations.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Custom Welded parts From all kind of carbon steels,stainless steels,aluminum,copper,Brass. We can produce weled parts from GTAW (Gas Tungsten Arc Weld),SMAW (Shielded Metal Arc Welding), MIG Welding (melt inert-gas welding),TIG Welding(Tungsten Inert Gas Welding) and laser welding for high quality required parts. Our Factory have may spot welding machines,butt welding machines, Argon shielded arc welding machine, Most welded metal parts use spot welding, the spot welding is the fastest way for small welding points, so say its spot welding. its can weld a net metal parts with many spots in consecutive. The welding services are widely use for welded brackets, welded wire frames, welded covers, welded studs on plates. Welcome contact us to discuss your welded metal parts.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The new CX series all-purpose large robots are equipped with a light and large arm with a hollow structure and a new universal control unit. They are large all purpose robots for a variety of applications for assembly, spot friction welding, machine loading, material handling, material removal, sealing/metering, spot welding, material handling, etc.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The new CX series all-purpose large robots are equipped with a light and large arm with a hollow structure and a new universal control unit. They are large all purpose robots for a variety of applications for assembly, spot friction welding, machine loading, material handling, material removal, sealing/metering, spot welding, material handling, etc.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The new CX series all-purpose large robots are equipped with a light and large arm with a hollow structure and a new universal control unit. They are large all purpose robots for a variety of applications for assembly, spot friction welding, machine loading, material handling, material removal, sealing/metering, spot welding, material handling, etc.

Request for a quote

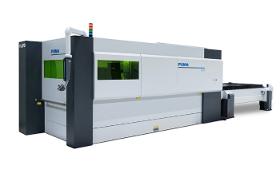

THOMSON MACHINERY BV

Netherlands

with 6kW fiber laser and MP Flex loading and unloading for sale in top condition. C0z3xdk3ol

Request for a quote

EC PLAZA

South Korea

GOGS CO., LTD. has received presidential award in 2008 for our patent technology at KINPEX. Our machine is highly specialized in heavy industry such as marine engineering, shipbuilding and etc. Our machine SHI(Samsung Heavy Industry), STX shipbuilding, Seongdong Shipbuilding & Marine Engineering, Hanjin Heavy Industries and etc. - 2-CORE control using PLC-CSI communication technology - High quality welding of 1mm thin plate at a distance (up to 100mm) - Lightening and decrease in failure rate using the All In One Cable - Multi-feeder that is possible to set operation conditions of a welding machine (Control of crater current and voltage, Power supply for auto carriage providing error messages) - Memory function of welding conditions - IoT function for smart control - Maximization of interlocking with auto welding machine (Smart welding Integration System(C-SWIS)

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

CNC laser cutting is a widely used manufacturing method in the industry. Although lasers were invented in the 20th century, their integration into light industry became prominent only after the turn of the millennium. Combining laser technology with computer precision, CNC laser cutting provides high efficiency and safety, which would be challenging to achieve with manual operation. In Istanbul, many CNC laser cutting companies are concentrated in areas like Ikitelli and Dudullu. These professional machines are essential for custom CNC work and are employed by various businesses for their extensive capabilities.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

In recent years, TIG welding has faced increasing competition from continuously refined MIG/MAG processes and their derived methods. Despite the slower welding speeds and lower melting power of TIG, it remains unmatched in achieving the highest quality results for many applications. Recent advancements in power supply technology offer promising future opportunities for TIG welding.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

CNC laser cutting is a widely used manufacturing method in the industry. Although lasers were invented in the 20th century, their integration into light industry became prominent only after the turn of the millennium. Combining laser technology with computer precision, CNC laser cutting provides high efficiency and safety, which would be challenging to achieve with manual operation. In Istanbul, many CNC laser cutting companies are concentrated in areas like Ikitelli and Dudullu. These professional machines are essential for custom CNC work and are employed by various businesses for their extensive capabilities.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

In recent years, TIG welding has faced increasing competition from continuously refined MIG/MAG processes and their derived methods. Despite the slower welding speeds and lower melting power of TIG, it remains unmatched in achieving the highest quality results for many applications. Recent advancements in power supply technology offer promising future opportunities for TIG welding.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

CNC laser cutting is a widely used manufacturing method in the industry. Although lasers were invented in the 20th century, their integration into light industry became prominent only after the turn of the millennium. Combining laser technology with computer precision, CNC laser cutting provides high efficiency and safety, which would be challenging to achieve with manual operation. In Istanbul, many CNC laser cutting companies are concentrated in areas like Ikitelli and Dudullu. These professional machines are essential for custom CNC work and are employed by various businesses for their extensive capabilities.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

In recent years, TIG welding has faced increasing competition from continuously refined MIG/MAG processes and their derived methods. Despite the slower welding speeds and lower melting power of TIG, it remains unmatched in achieving the highest quality results for many applications. Recent advancements in power supply technology offer promising future opportunities for TIG welding.

Request for a quote

VIRMER

Netherlands

Advantages of Laser welding: High welding speed (1-10 m/min). Welding without edges grooving. Minimal warp distortions. Minimal heat-affected zone. Applicable for welding of wide variety of materials. Welding process versatility. Possibility of automatization. Energy and wire saving. Comfortable labor conditions, working area maintained clean. Readme! Laser welding has a special property – it forms a high-density welding joint. Porosity and other defects that are inhere in other welding methods, are absent using this technology.

Request for a quote

VIRMER

Netherlands

Advantages of Laser welding: High welding speed (1-10 m/min). Welding without edges grooving. Minimal warp distortions. Minimal heat-affected zone. Applicable for welding of wide variety of materials. Welding process versatility. Possibility of automatization. Energy and wire saving. Comfortable labor conditions, working area maintained clean. Readme! Laser welding has a special property – it forms a high-density welding joint. Porosity and other defects that are inhere in other welding methods, are absent using this technology.

Request for a quote

SINOP SMP

Czech Rep.

Standing transformer welding sources with swinging arm Digital Control Unit Maximal sheet thickness 5 + 5 mm Steel, Stainless steel Aluminum alloys

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VAN EYCKEN - METAL CONSTRUCTION

Belgium

You can rely on us for traditional laser work. We offer our advanced flatbed laser services, powered by the powerful FinPower L6 laser. This reliable machine takes your sheet metal processing to new heights, with the capability to cut and shape sheet material up to 15 mm thick with precision. The impressive power of our L6, driven by a 4 kW CO2 laser, allows you to maximize your projects. Additionally, we offer the flexibility to engrave unique part numbers, giving you control over the identification of your pieces. In our workshop, your pieces can be further processed with machine sanding and deburring, eliminating the need for post-processing. This allows us to provide a complete solution for your projects. Discover the versatility of our laser services and the comprehensive support we offer.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Our laser tube cutting service includes all major tube and section profiles – including large tube laser cutting – with specialist profile capabilities accommodated with ease. Continuous investment ensures we can always offer our customers the broadest capabilities, so they remain at the forefront.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Achieving a cutting tolerance of +-0.25mm, lasers are firmly established as the accurate cutting technology. Capable of achieving fine contours and intricate cuts in seconds, laser cutting is leading the way in manufacturing efficiency gains.

Request for a quote

FOXLASER

Bulgaria

FoxLaser offers all types of welding of ferrous and non-ferrous metals: 7-axis robot cell for MIG/MAG welding. Positioner up to 5 tons. MIG/MAG – electric arc welding in a protective gas environment with a melting electrode. TIG – electric arc welding in a protective gas environment with a non-melting electrode and with automatic supply of additional material. TIG MICRO-WELDING with PUK-U3. MAW – manual metal (electric) arc welding. SPOT electric resistance welding. We have 3D welding tables for assembling complex sheet and tubular structures. Their dimensions are 3000/1500/200 mm and 2400/1200/200 mm. The use of special attachments and fixtures or the assembly of several tables together makes it possible to increase the size of the assembled structures.

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

LUMIMAX® LED Spot Lights are very compact and powerful. They are characterised by an extremely high light intensity. Because of various available and adjustable optics with their very homogeneous light, LED Spot Lights can illuminate very small surfaces directly and focused. Their compact design allows an optional arrangement around the testing object. The High Power LED Spots are available for either continuous operation or flash operation. TThe built in precision lens of the Spot5W enables a very focussed, selective and high-intensity illumination, even at working distances larger than one meter.

Request for a quote

YILDIZ POLIETILEN LTD. CO.

Turkey

We produce electrofusion machines that can weld diameters from 20mm to 1600mm.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Welding construction as required No matter whether pipes, small parts or large components - the welding construction department of Siempelkamp Maschinenfabrik GmbH is able to fulll your wishes thanks to its high-performance machinery. Our welding specialists are able to produce your components using MIG, MAG, UP, TIG, Emanual and electro-slag processes. Numerous certicates attest to the highest quality of our welding work. Key features procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Advantages procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Application of the most ecient welding process for your component Highest quality standards through certied welding work economic production of tubes by our forming and necking machine

Request for a quote

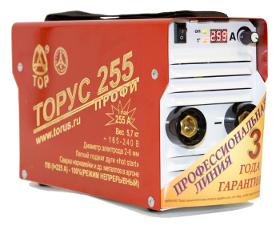

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

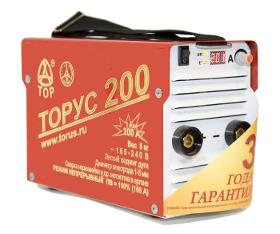

COMPANY TOR

Russia

ТОРУС-200 is a modern welding inverter device based on a digital high-frequency mains voltage transducer. The device is designed for electric arc welding of low-carbon, alloy and stainless steels, it can operate in TIG and MMA modes. Obtaining high-quality welding joints does not require high qualifications from the employee, which is important for novice welders. In short-circuit mode, the device almost does not consume current, which allows it to be powered from petrol power units with a capacity of 4 kW (6 kVA) and a household network with slumps up to 165 V. ТОРУС-200, like other inverter welding machines of the ТОРУС line, allows you to get welding with stable parameters. It is characterized by: small weight – 5 kg, high performance factor and the ability to work with electrodes with a thickness from 1.6 to 5 millimeters. In addition, the ТОРУС-200 welding inverter is designed for continuous operation not only indoors, but also outdoors.

Request for a quote

SNOWBIKE LLC

Russia

Fiber optic welding machine L-WELD is designed to weld metal plates and pipes. Fiber laser creates a high-frequency beam, which is focused in one spot. This concentrated laser source provides thin, deep welding and is of high speed.

Request for a quote

KLN ULTRASCHALL AG

Germany

The KLN QSW 400 L is a modular laser welding machine. The advantage of the modular structure is that the central laser welding machine can remain unchanged in the various welding tasks and only the housing and its frame structure must be adapted to the actual welding task. Thus, a well-tried laser welding unit can always be used. Moreover, adaptions to other welding tasks can be easily integrated, e. g. with rotary table, tool carrier, conveyeor or sliding table. Laser: Water-cooled diode laser with 300 W optical output power Wave length 980 nm ±10 nm Pilot beam at 650 nm ±15 nm (<1 mW) Optical fibre suitable for wave length 780-1030 nm Focal distance of collimation 58 mm Focal distance f-theta objective 635 mm Operating distance 728 mm Operating field (scan field) 415 mm x 415 mm

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

The Frame Welding Machine is made of welded parts of different sizes and is designed to obtain the desired special H profiles. The machine body and the welding heads are fixed and the workpiece provide to be welded on both sides of the part to be welded by moving by means of driven conveyors. The hydraulic cylinders in the system provide the positioning of the H profile placing and fixing during welding.The system has adjustable backrests and accessories for the roofing of the conveyor group.The system has a hydraulic piston loading unit. The system might turn beam 90 degree with maximum weight and maximum dimensions by means of chain or mechanical structure.

Request for a quoteResults for

Spot welding machines - Import exportNumber of results

38 ProductsCountries

Category

- Laser - cutting and welding machines (24)

- Autogenous welding machines (6)

- Welding, soldering and brazing - equipment and supplies (3)

- Automation - systems and equipment (2)

- Welding work - steels and metal (2)

- Copper and copper alloys (1)

- Electron beam welding - equipment (1)

- Foundries - copper, bronze and brass (1)

- Industrial robots (1)

- Lighting, street, industrial and commercial (1)

- Milling - steels and metals (1)

- Welding robots (1)

- Welding, electric - equipment and supplies (1)