- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam condensers

Results for

Steam condensers - Import export

KASAG SWISS AG

Switzerland

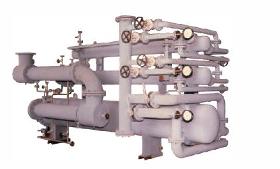

You state your requirements and send us the material properties. KASAG then configures the thermal and hydraulic calculations for the desired heat exchanger. The realization is implemented according to the available drawings or on the basis of a comprehensive engineering. KASAG offers all processes necessary for that, such as the orbital-welding process for manufacturing heat exchangers. With KASAG, you can be sustainably flexible.

Request for a quote

DELTAFLUID

France

For steam applications, condensate pots are essential. They are used to condense the fluid upstream of the differential pressure transmitter. Installed at the same height, they allow accurate measurement by maintaining a constant condensate height in the impulse lines above the differential pressure transmitter. The condensation pot can also be used to protect the transmitter in the case of a flow measurement of a corrosive / aggressive fluid. In this case we speak of separation pots. For more information, see the Frequently Asked Questions tab on this page.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

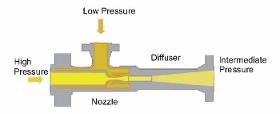

Three Stage Ejector is similar in construction as of Single Stage Ejector, but having intermediate condensers. Three Stage Ejector comprises of Booster Ejector, Booster condenser and a Two Stage Ejector. And Two Stage Ejector consists of a high vacuum ejector, a inter condenser and a low vacuum ejector. This system will give higher vacuum and can handles larger quantity of condensable vapors. Gas or Gas vapor mixture is discharged from the first stage into the condenser where the operating steam is condensed and gases are cooled. The cooled gases are then entrained by the second stage and discharged into the second inter condenser. Here, the steam used in the second stage is condensed. The gases are finally entrained by the third stage and discharged to atmosphere.

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The Steam Surface condenser is a critical component of both the traditional coal fired power plant and the new generation cogeneration and combined cycle power plants. Main duties of any Surface Condenser are to convert the exhaust steam from its gaseous to its liquid state at certain under atmospheric pressure, and also, to release non condensable presented in the steam cycle, together with vacuum unit. Jet Flow designs and economically sized condenser suitable for smaller turbine ratings under 100 MW. The circular configuration is compact for easy shipping and maintains the level of quality afforded all of our condenser designs. All of Jet Flow’s Surface Condensers are designed and built to the Heat Exchange Institute latest Standards. We also strive to meet all of our client’s project specific requirements.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS gland steam condensers: - Can be used in regenerative and conventional applications - A complete system including blowers - Materials are adapted to the relevant application - Acceptance currently according to PED 2014/68/EU and the ASME Code; additional certifications to follow

Request for a quote

APROVIS

Germany

* High-temperature heat exchangers * Gland steam condensers

Request for a quote

ZEPTER INTERNATIONAL

Switzerland

LID: it is heavier than most classic lids, fits perfectly on the edge of the container and seals it hermetically with a water ring, which enables a closed circular cooking cycle and the food retains its nutritional properties. The Zepter cover can be stored on the patented Zepter handles, to save space on the workbench. Presentation HEALTHY FOOD COOKING SYSTEM: Zepter has developed a food preparation process in which the water vapor released from the food rises to the lid, which is always cooler than other parts of the container. In contact with it, the steam condenses and drops of liquid fall on the food in the container. The process is repeated until the food is perfectly cooked. The Zepter closed circular cycle guarantees the preparation of healthy food, without adding water or fat, always at low temperatures.

Request for a quote

AZA GLOBAL IMPEX B.V

Netherlands

Experience the taste of authentic North African dishes with our tagines. This unique cooking pot consists of a wide, shallow base and a conical lid, through which the steam condenses and returns to the dish. The result is a juicy and tasty meal full of delicious aromas.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Secure use of condensate in steam boiler systems — Decreases in energy and water consumption due to reduced quantities of make-up water — Minimisation of flash steam losses, desalting and blowdown quantities; reduced consumption of chemicals — Reduced corrosion potential in the steam condensate system when using high-pressure condensate systems

Request for a quote

DELTAFLUID

France

Many piping and instrumentation accessories are necessary to implement the flow measurement of a fluid in a pipe: the shutters to isolate the existing pipe in case of intervention, the flanges to fix the primary elements and to connect to the existing process, flow straighteners or flow conditioners to stabilize the flow before the measurement but also condensation pots for steam measurement and finally manifold, pressure transmitter always mandatory for differential pressure flow measurement.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners is the one-stop-shop for steam turbine maintenance. We have all the expertise needed for complete overhauls, repairs, reconditioning, upgrades, revamps and relocations of steam turbines, regardless of type or make. Our rotorshop performs all aspects of rotor-, diaphragm & blade carrier repairs, ranging from NDT inspections to high speed balancing. We service all types of axial and radial steam turbines (multistage and single stage steam turbines): Impulse turbines Reaction turbines Condensing steam turbines Non – condensing steam turbines Steam Turbine Brands Served: ABB – AEG KANIS – ALLEN – ALSTOHM – ALSTOM – ANSALDO – ASEA STAL – BBC – BLOHM & VOSS – COPPUS DEMAG – DELAVAL – DEAN HILL – DOOSAN SKODA – DRESSER RAND – KOBE – FINCANTIERI – FUJI – GENERAL ELECTRIC (GE) – GHH – NUOVO PIGNONE – KKK – MAN TURBO – PETER BROTHERHOOD – RATEAU – SULZER – STAL-LAVAL TURBIN – TRIVENI – ELLIOTT – SIEMENS – THERMODYN – TUTHILL – WORTHINGTON – … Steam Turbine Maintena

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Four Stage Ejector with Condenser Four Stage Ejector is having construction and working similar to Single Stage, Two Stage & Three Stage Ejector. When ejector is to be installed at low ambient temperature area, primary booster should be steam jacketed to prevent building up of ice on the diffuser internal bore. Sometimes both primary and secondary boosters are completely jacked to avoid deposition of product inside the ejector. The Four Stage Ejector consists of following components Primary Booster Ejector Secondary Booster Ejector Booster Condenser Vacuum Ejector Inter Condenser Low Vacuum Ejector

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

When it comes to the performance of a turbine surface condenser in the operational field of a steam turbine cycle, you need utmost reliability and efficiency. Here’s where Jet Flow’s know how is invaluable. We createcustomise package solutions for each particular customer’s needs. Our General Scope of Supply Condenser Circular Condenser having own Flow, Axial flow or side inlet steam entry. Turbine to Condenser steam duct, including necessary expansion joints. Steam Jet Ejector Vacuum System. Flash tank, drain header and Instrument stand pipe. Dump Tube. Condensate Pump system Pumps are in vertical or horizontal arrangement; either API 610, ISO 5199 or standard manufacturer pump design. Control system Including level control valves pressure and temperature indicators, transmitters and controllers. Interconnecting piping with filter, fittings and valves.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Five Stage and Six stage Steam Jet Ejectors with Condenser Five stage and six stage ejectors are designed for absolute pressure in Micron Range. The arrangement of these ejectors is similar to the four stage ejector with additional one or tow non condensing stages. Special Precautions while measuring Low Absolute Pressures : Do not use spring type vacuum Gauges Ensure that the guage tubes are clean and free form contamination Ensure that the guage liquid is clean and free from contamination

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The needs of the power generation industry include year in and year out reliability, optimum performance for maximum efficiency, and absolute on time delivery to meet plant outage schedules. All of the Jet Flow Boiler Feed Water Heaters are designed in accordance with HEI standards, TEMA and ASME codes. Jet Flow uses state of the art computer programs to perform the thermal hydraulic and mechanical design of each Feed Water Heater we fabricate. Jet Flow designs and manufactures both Low Pressure (LP) and High Pressure (HP) feed water heaters which may be installed either vertically or horizontally, depending on the plant design requirements. Each Jet Flow Feed Water Heater will contain from one to three separate heat transfer areas of zones including the Condensing, Desuperheating and Subcooling zones. Our heaters can be provided with multiple zones within the shell side Condensing Zone Included in all heaters,steam is condensed in this zone and non condensable gases are removed.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The efficiency of a Steam turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for makeup admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Pressure vessel is used (according to site function) for fluid storage, steam condensation, level measurement… Construction code: NF EN 13480, RCC-M, ASME, CODAP SPM capability: DN50 to DN400 Raw material: Stainless steel (304L, 316L…) Carbon steel (P265GH, 16Mo3, 13CrMo4-5…)

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Keep Your Steam Clean, Safe And Energy-Efficient Steam is an essential resource is many industrial processes. As a result most facilities have a vast network of piping, valves, flanges and steam traps. Within these systems there exists constant flow and turbulence. As pure steam travels from your boilers to their point of use, some cooling is inevitable. The result is accumulated condensate and gases. Steam traps purge this waste and keep your system pure. A fully-functional steam trap opens, closes or modulates automatically. It discharges condensate once formed, unless the heat from the condensate can be used. It is energy-efficient and does not waste quality steam. It removes impurities from the live steam, and maintains purity and efficiency throughout the system. Steam Trap Failure Causes Losses to Product Quality, Safety and Energy Loss Steam traps are necessary for the overall efficiency of heat energy transfer.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quote

BIMAKS KIMYA VE GIDA DIS TIC. LTD. STI.

Turkey

GENERAL DESCRIPTION MAKS 1300 is an aqueous blend of the neutralizing amines. PRINCIPAL USES MAKS 1300 is a neutralizing corrosion inhibitor designed for use in steam and complex condensate systems. MAKS 1300 can be used at steam pressures up to 160 bars and temperatures up to 4790C. REMARK: MAKS 1300 is in compliance with FDA regulations pertaining to boiler water additives. Maximum dosage in plants subject to FDA regulation does not to exceed 45 ppm in the steam. MAKS 1300 must not be used where the steam produced will contact milk or milk products. PRODUCT BENEFITS Neutralizes acid-forming gases like CO2 Provides corrosion protection in initial, middle and extended areas of condensate systems Reduces condensate system maintenance cost Minimizes boiler tube failures caused by corrosion product in returned condensate

Request for a quote

SUZHOU X CHEMICAL CO.,LIMITED

United States

"Condensate Polishing is normally applied to the treatment of condensed steam from turbines operating in the power industry. It is a specialty application where ion exchange resins are used for removal of corrosion transport products as well as removal of trace ionic impurities. This requires the use of resins that have excellent filtration characteristics as well as ion exchange capacity, and that can withstand the high temperatures and flow rates encountered in condensate systems. Polishing resins must also have low levels of both organic and ionic impurities such that they do not leach any objectionable contaminants into the treated water Suzhou X Chemical offers a variety of coarse grade and uniform particle size resins specifically for condensate polishing, including highly crosslinked resins with excellent thermal stability. These resins are available in a variety of ionic forms such as ammonia and amine forms for cation resin and hydroxide form for anion resin, suitable for imme

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Durability and corrosive resistance are key criteria when it comes to precision thin wall tubing for industrial condensers. The tube mill at Superior Tube more than meets that requirement, and we supply products to a range of leading engineering companies. In the energy sector, our high quality stainless steel and nickel alloy condenser tubes are used for the cooling, heating or re-heating of fluids or gases within steam turbines that generate electricity. Condenser tubing products can be purchased from Superior Tube as seamless, welded or welded drawn tubes in a multitude of sizes ranging from 0.010” OD to 1.500” OD with wall thickness as light as .003” Please note that we have a minimum order value of £10,000.

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quoteResults for

Steam condensers - Import exportNumber of results

39 ProductsCountries

Category

- Steam turbines (10)

- Gas and oil - exploitation (8)

- Oiling - machines and systems (4)

- Heat exchangers (2)

- Wood veneer - machinery and equipment (2)

- Boilers, industrial (1)

- Boilerwork (1)

- Condensers (1)

- Monitoring and control equipment (1)

- Ornamental pottery (1)

- Pipe and tube fittings - non-ferrous metal (1)

- Presses, hydraulic (1)

- Seamless pipes and tubes - ferrous metal (1)

- Tableware (1)

- Turbine-driven power stations, installations and equipment (1)

- Water purifying products (1)

- Water treatment products (1)