- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting%20machines

Results for

Cutting%20machines - Import export

UNITED PROARC CORPORATION

Taiwan R.O.C.

The Ocut series provides unmatched performance, reliability, and flexibility in thermal cutting production environment. 1.Cutting diameter from 50~900mm 2.Working length 6000mm or 12,000mm 3.Support straight or bevel plasma cutting. 4.Rotation with self centering pipe fixture. 5.Height adjustable rotator. Save/Load each job's rotator height. 6.High torque drive system. 7.Dustproof high precision linear guide ways. 8.Self-aligned plasma torch collision holder. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine 1. Advanced CNC controller - high performance control system 2. High accuracy - ±0.1mm 3. Precision linear way with copper cover for durable lifetime 4. Rigid structure, strong and precision grinding I-rail. 5. Gas control system for Oxyfuel cutting 6. Cutting thickness max. 300mm 7. Durable sealed cable chain for X&Y axes with better protection 8. Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1. IHT automatic flame cutting torch 2. Plasma / oxyfuel bevel cutting 3. Tube cutting 4. Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 5. Nesting Software 6. Center drill device 7. LED lamp 8. Anti-spatter spray device *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High performance cutting machine with excellent cutting quality. 1. High positioning accuracy - ±0.1mm 2. Bridge structure - High strength, long life 3. Precision track units 4. High torque drive system 5. Vertical drive mounting bracket offer the best motion performance 6. CCD Camera 7. Laser protection glass windows to protects from laser beam exposure 8. Add-on options Available to Enhance Efficiency and Performance. 9. Cuts and Marks Various Metal Types.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

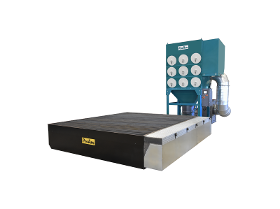

Metal fume and dust come from CNC plasma cutting is always harmful to our healthy, how to efficiently collect these pollution is always a headache to customer. ProArc special design dust collector (filter system) will help customer solve these issue and provide a healthy working environment in a cost saving way with following features: 1. In house installation 2. Fire resistant nanofiber filters 3. Build-in spark trapper 4. Smart control 5. Auto clean 6. PLC with HMI system, easy for operation. 7. Long life filter & 99.95% filtration efficiency 8. Quick relief cover for filter replacement. 9. Compact design, save floor space. 10. Inverter fan for low energy consumption. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Metal fume and dust come from CNC plasma cutting is always harmful to our healthy, how to efficiently collect these pollution is always a headache to customer. 1.We offer "One-Shop service" for CNC cutting machine / Fume collection table / H-beam foundation / Dust collector for customer. 2.ProArc special design high efficiency fume collection cutting table and fume collection duct will help customer solve these issue and provide a healthy working environment in cost saving way. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

We provide the machine configure with Smart focus 300 and 400. This configuration provides the very high performance of cutting quality and long life of consumables.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Athlete is the advanced table type cutting system designed for speed and precision, best suited for high definition plasma cutting operation. 1.All-in-one compact design 2.Outstanding cutting quality and accuracy. 3.High efficiency sequential zone fume collection table ready for use. 4.Easy installation and minimum setup time. 5.Maximum working width with minimum space requirements. 6.Cutting effective 1530x3000mm / 1800x3000mm 7.Available for both plasma and oxygen torch *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Compact CNC cutting machine built for 100% duty cycle cutting operation. 1. Rugged and sturdy 2. Cutting effective 1200x1200mm / 1200x2400mm / 1500 x 3000mm 3. Available for both plasma and oxygen torch 4. Cutting table is suitable for both water and fume (two way use table) 5. Suitable for job shop looking to add their first piece of automated machinery 6. Easy for installation. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc Magicut is a cost effective cutting solution in its class. 1. Rigid structure, strong and precision grinding T-rail 2. Gas control system for Oxyfuel cutting up to 4 oxygen torches. 3. Durable sealed cable chain for X & Y Axes with better protection 4. Operator platform - Flip down chair design suitable for production and maximize operation space *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine designed to be a reliable, cost effective machine in streamline appearance for high performance cutting requirements. 1.Advanced CNC controller - high performance control system 2.High accuracy - ±0.1mm 3.High bevel speed 4.Precision linear way - with copper cover for durable lifetime 5.Rigid structure, strong and precision grinding I-rail. 6.Automatic torch height control 7.Durable sealed cable chain for X & Y axes with better protection 8.Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1.Oxyfuel cutting torch 2.Tube cutting 3.Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 4.Nesting Software 5.Center drill device 6.LED lamp 7.Anti-spatter spray device *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine 1. Advanced CNC controller - high performance control system 2. High accuracy - ±0.1mm 3. Precision linear way with copper cover for durable lifetime 4. Rigid structure, strong and precision grinding I-rail. 5. Gas control system for Oxyfuel cutting 6. Cutting thickness max. 300mm 7. Durable sealed cable chain for X&Y axes with better protection 8. Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1. Hypertherm / Kjellberg plasma power source 2. Bevel cutting 3. Oxyfuel cutting torch 4. Tube cutting 5. Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 6.Nesting Software 7.Center drill device 8.LED lamp 9.Anti-spatter spray device *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

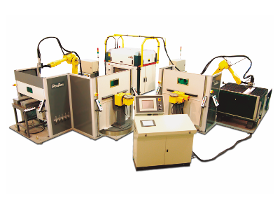

Intelligent manufacturing Full automation Custom design For TIG, MIG, Plasma or other welding process

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc have a significant developing in welding automation system for electronics Industry. We help our customer who are the famous battery manufacture in the world to develop the laser sealed welding for laptop battery. Industry 4.0 Intelligent manufacturing Full automation production Sealed laser welding With CCD Camera check welding quality in real time Custom design for electronics industry

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc help our customer in impeller pump manufacturing industry to develop the laser welding production procedure. Better sealed laser welding quality to let the impeller pump performs high efficiency and increase productivity. Industry 4.0 Intelligent manufacturing Full automation production Custom design for automotive industry

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc helps our customer to develop the laser welding automation system in Golf clubs manufacturing industry. Integrated with Fanuc robot system and Rofin laser, we provide a total solution for our customer both in laser welding and laser cutting. Industry 4.0 Intelligent manufacturing Full automation production Custom design for automotive industry

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Tailor Welded Blanks (TWB) in different material and different thickness plate joint is normally achieved by laser welding and is generally used in automobile industry especially for ultra high strength steel welding. It helps to reduce the material consumption and total weight but keeping same technical performances. Industry 4.0 Intelligent manufacturing Full automation production

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

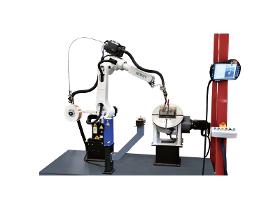

ProArc and HIWIN bring robot application to a intelligent and remarkable milestone in welding industry through the new weld robot system. System comes with full package including Cut wire Work station w/Multi Task Modular cells To define robot in the COORD export system Pass [Position Register] function to make function infinity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom L lever part is made by material stainless steel, investment casting / lost-wax casting in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: investment casting parts, lost-wax casting parts Product size: 115*100*90 mm, as customer’s required Material: aluminum Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: investment casting, lost-wax casting Surface treatment: Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: pipe connector, as customer’s required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom brass tube part is made by material brass, die-casting, machining, and zine-plating in Taiwan which base on customer’s requirement and meet the ISO certification. Product type: die-casting parts Product size: 95*85*52 mm, as customer’s required Material: brass Material available: zinc, brass, copper, aluminum, as customer’s required, zinc Tolerance: normally UNI-ISO 2768, as customer’s required Processing: die-casting, machining, zinc-plating Surface treatment: zinc-plating Packing: as customer’s required Measurement:2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

JING DUANN MACHINERY INDUSTRIAL CO., LTD

Taiwan R.O.C.

Application: (Automatic clamping, feeding, positioning and cutting tooling movement) Solid and precise structure with perfect lubrication system to achieve longer service life in large volume production and extended working time. It is suitable for steel round bar cutting work.

Request for a quote

GIP TECHNOLOGY CORPORATION

Taiwan R.O.C.

GIP Technology 532nm Fiber Laser unit for Industrial applications, are designed to provide a combination of high power of 5W, high stability, and ideal beam quality. The fiber lasers are widely used for fiber sensor, medical, nonlinear optics research, and measurement applications.

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

"Work piece diameter(mm) Ø6 ~ Ø50 Pitch(mm) 0.8P ~ 6.0P, M:0.3 ~ M:1.5 Length of thread rolling(mm) 98MAX Spindle speed 15, 20, 30, 45, 60, 70 r.p.m Thread rolling die(mm) Diameter Ø200MAX Bore Ø70 Length 35,70,100 Keyway 14 X 7 Distance of the rolling spindles(mm) 155 ~ 255 Output (pieces/min) 4 ~ 15 Main power motor 10 HP 6P (7.5 kw) Hydraulic motor 5 HP (3.7 kw) Max rolling pressure 40 TONS Net weight 4050 kgs Gross weight 4450 kgs Overall dimension 1900 x 2300 x 2300 mm Shipping measurement 1800 x 2300 x 2250 mm"

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Work piece diameter(mm) Ø18 ~ Ø60 Axial pitch for ISO threads(mm) 1.0P ~ 6.0P Length of thread rolling(mm) Plunge rolling(In feed):48 Thru feed rolling:no limited Spindle speed 220、350、580、720r.p.m Thread rolling die(mm) Diameter Ø120 Bore Ø40 Length 25,50 Keyway 8 X 4 Distance of the rolling spindles(mm) 105 ~ 190 Output (pieces/min) 4 ~ 25 Swivel of roll-axis ± 3° Main power motor 5HP 6P(3.7kw) Hydraulic motor 3 HP (2.2 kw) Max rolling pressure 12 TONS Net weight (Approx.) 1300 kgs Gross weight (Approx.) 1450 kgs Overall dimension (L x W x H) 1600 mm x 1500 mm x 1600 mm Shipping measurement (L x W x H) 1450 mm x 1400 mm x 1700 mm

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Thread rolling machines are used to produce screws, bolts, and tools. The blank is pressed by thread rolling dies which are attached to the thread rolling machine . The Cam type thread rolling machine is adopted the mechanical cam feed to complete the thread rolling motion, and the precise feed positioning can be ensured. Feature: UM-35 thread rolling machine is suitable to roll standard screws, bicycle pats, automobile arts,.....and various machinery parts. UM-35 thread rolling machine is equipped with the precise work shaft and work gear which keep the steady transmission, and the accuracy of thread profile. UM-35 thread rolling machine is with the precise transmission grinding type gear shape, therefore, noise-free, durable, precisely, and no extra space when transmission are able to be ensured. UM-35 thread rolling of the dove tail-type slide for assuring that jumping, vibration, and wear will not happen during rolling progress.

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Work piece diameter(mm)Ø10 ~ Ø75 Axial pitch for ISO threads(mm) 1.0P ~ 10.0P Length of thread rolling(mm) Plunge rolling(In feed):148(75A:200) Thru feed rolling:no limited Spindle speed 20 ~ 50 r.p.m variable speed Thread rolling die(mm) Diameter Ø200(75A=Ø250)MAX Bore Ø70(75A= Ø85) Length 35,70,100,150(75A=70.100.150.200) Keyway 14X7(75A=18X9) Distance of the rolling spindles(mm) 275 ~ 195(75A:300~220) Output (pieces/min) 4 ~ 20 Swivel of roll-axis ± 6° Main power motor 25 HP (18.75 kw)(75A=30HP) Hydraulic motor 7 1/2 HP (5.5 kw)(75A=10HP) Max rolling pressure 60 TONS Net weight (Approx.) 4,700 kgs Gross weight (Approx.) 5,200 kgs Overall dimension (L x W x H) 2,600 mm x 2,400 mm x 2,400 mm Shipping measurement (L x W x H) 2,520 mm x 2,240 mm x 2,230 mm

Request for a quoteResults for

Cutting%20machines - Import exportNumber of results

26 ProductsCountries

Company type