- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermal processing

Results for

Thermal processing - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

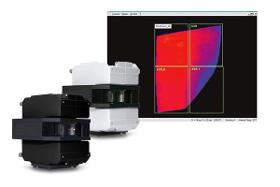

The GS Thermal Imaging System for Glass Processes from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and low emissivity glass products. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized glass applications – such as glass bending, forming, annealing and tempering – and industrial environments. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field-of-view and up to 200:1 optics, each spot on the target surface is capable

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

The search for solutions in the field of process engineering systems and methods presents us with new challenges every day. Electric heaters for the direct thermal treatment of incoming air in air conditioning systems or as preheater or afterburner for intake air in industrial equipment using intelligent processadapted control systems are gaining an increasing acceptance

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

Typical Fields of Application are in the chemical, petrochemical, railroad and shipbuilding industries, in the machine and industrial equipment construction. CSN® circulation heaters are manufactured in close coordination with our customers from a few watts to the megawatt range, a division in individual circuits is made according to customer’s requirements. Equipment for installation in hazardous areas we produce in protection class „Ex d“, „Ex de“, „Ex e“. On request, CSN® circulation heaters are supplied with optimized process controls. Please contact us to talk about the most appropriate control system. Schniewindt is certified by the Lloyd’s Register to produce equipment according to the Pressure Vessel Directive 2014/68/EU and a certificate from TÜV (Technical Monitoring Agency) certifies that we meet the prerequisites for welding procedures according to AD 2000 Merkblatt HP 0 / DIN EN 7293.

Request for a quote

MARXAM PROJECT

Poland

The technology of laser cutting pipes and profiles has two main advantages compared to traditional processing methods: - tube cutting allows for a significant reduction in the costs of preparing sections for further production; - laser tube cutting services allow the use of many new construction and technological solutions. Our 3D laser profile cutting and 3D welding systems are ideal for machining 2D and 3D components or tubes. The ability to flexibly switch between cutting, welding and laser cladding allows for maximum production efficiency, and the dynamic, optical cutting system significantly reduces processing time. An additional advantage of industrial laser cutting for serial production is the possibility of working in a rotational mode – during the operation of the machine, it is possible to unload and load new elements for processing.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner Automatic temperature and quality monitoring in continuous web processes Detect thermal problems early Faster product changes and reduced setup time Communicate with process control system via OPC Reduce scrap APPLICATIONS Plastics, metals, paper, and building industries, combustion prevention, hotspot detection, flat and float glass production, automotive, food processing and numerous other industrial applications FEATURES Onboard Ethernet TCP/IP communication Product specific configurations or “recipes” Custom measurement sectors Optional analog and digital outputs for each sector Analog outputs 3 x 4 – 20mA PC-independent alarm output Visualisation on PC Software supports English, German, French, Finnish, Dutch and Italian languages

Request for a quote

PRAXAS B.V.

Netherlands

The Lascar EL-USB-TC Thermocouple Temperature Logger is specifically designed for use with thermocouple sensors. This temperature logger stores over 32,000 temperature readings from a Type J, Type K or Type T thermocouple. The data logger is supplied, including a K-type sensor with a measurement range of 0 to 200°C. With this data logger, for more than 32,000 readings, you can very simply gain insight into thermal processes. This data logger from Lascar is a reliable and time-saving tool for measuring temperature in places where a normal temperature logger cannot reach, for example, in fruit and vegetables.

Request for a quote

NOREVO GMBH

Germany

Our low bac honey (low bacteria = germ-reduced) has been specially developed for microbiologically demanding and sensitive products. Our internally developed thermal process reduces germs by heating the honey.

Request for a quote

RAFI POLAND

Poland

Our company is specialized in the field of autograph paper (Carbonless Paper), A4 Paper, Paper Rolls and Thermal paper (Thermal paper roll), in trade, processing and in the Pack to Pack sector, with an emphasis on processing (slitting). Thermal paper rolls are available in all dimmensions with plastic or paper roller. Thermal paper is only available in jumbo reels, its substance is 55 gsm. Available in white colour.

FILTERTECHNIK JÄGER GMBH

Germany

Pleated Filter Cartridge Type: PPA Pleated PP-Membrane or nonwoven PP support nonwoven Hard cage Core + end caps made of 100 % polypropylene, meet requirements of FDA guidelines. Thermal welding processes seal all components No adhesives or extractable materials Version: DOE SOE 226 – O-Ring / Bayonet / Spear P7 SOE 222 – O-Ring / Flat P3 SOE 222 – O-Ring / Spear P8

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

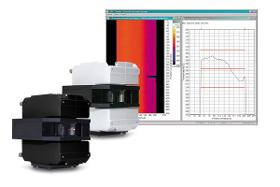

The Extrusion Coating EC Thermal Imaging System from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes.The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

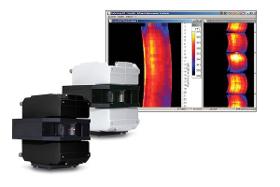

The TF Thermoforming Thermal Imaging System from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for thermoforming processes. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized applications and industrial environments. The TF Thermal Imaging System is ideal for applications reaching temperatures from 20 to 350°C (68 to 662°F). MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field-of-view and up to 200:1 optics, each spot on the target surface is capable

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

CRYOSNOW GMBH

Germany

• For automized applications • CO2 consumption is controlled by pressure and temperature • Compact design, overall length 134 mm (5.3") • Customer-specific robot adapter • Weight without robot adapter 3.9 kg (8.7 lb) • No water condensation due to high efficient thermal insulation • Process reliable and maintenance-free in permanent operation • Cleaning width 200 mm (7.8")

Request for a quote

CRYOSNOW GMBH

Germany

• Especially for automized applications • Very short, compact design, overall length including short flat nozzle 361 mm (14.2") • Installable as extension of the last axis of the robot • Overall weight including short flat nozzle 2.7 kg (6.0 lb) • No water condensation due to thermal insulation • Process reliable and wearless in permanent operation • Jetting width up to 125 mm (4.9") • For the cleaning of big surfaces in pretreatment before painting • For use with different nozzles

Request for a quote

CRYOSNOW GMBH

Germany

• Especially for automized applications • Very short, compact design, overall length including short flat nozzle 330 mm (13") • Installable as extension of the last axis of the robot • Overall weight including short flat nozzle 2 kg (4.4 lb) • No water condensation due to thermal insulation • Process reliable and wearless in permanent operation • Jetting width up to 125 mm (4.9") • For the cleaning of big surfaces in pretreatment before painting • For use with different nozzles

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Service Cleaning: Our customers count on our contract cleaning team for their daily cleaning needs -. With modern cleaning processes e.g. thermal with pyrolysis, aqueous with ultrasonic or mechanical with lapping blasting we can clean and improve your high quality tools. Whether extrusion or injection molding tools, extruder screws, hot runners, nozzles, filters, molds, screens, adhesive or coating devices - everything will be cleaned by us for you! Detailed advice and documented cleaning of samples ensure consistent results over a long period of time. Test us - In addition to comprehensive advice, we offer you the opportunity to carry out your own cleaning trials of workpieces up to a length of 3 m and / or 4 t in weight. Cleaning trials: Every customer can convince himself of our offer by a free sample cleaning. Whether cleaning, surface treatment or decoating - with us you as a customer can see the result even before the first order!

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

The Vacuum Chamber VC P700D is made of a unique, flexible chamber system based on extruded aluminium profiles. The three meter long profiles are cut to the desired length and equipped with a bolted rear wall and a door. ✓ Flexible length of max. 3 meters ✓ Very fast delivery because only door and back wall must be supplemented ✓ Low-cost ✓ Low-weight ✓ Low desorption of the aluminium, therefore also suitable for high vacuum ✓ Excellent thermal conduction ✓ Highly clean processes possible, e.g. in the semiconductor field ✓ Easy operation ✓ Easy attachment to the existing division bars Vacuum chamber specifications Internal dimensions Length: up to 3000 mm (standard: 1000 mm, 1400 mm) Inner diameter: 640 Ø Outer diameter: 700 Ø Front panel (optional): 18 U (1 U = 44.45 mm) Connections 2 x KF 16 2 x KF 40 2 x ISO K 63 Additional flanges possible in any position

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIENER ELECTRONIC GMBH & CO. KG

Germany

The Vacuum Chamber VC P400X600 is made of a unique, flexible chamber system based on extruded aluminium profiles. The three meter long profiles are cut to the desired length and equipped with a bolted rear wall and a door. ✓ Flexible length of max. 3 meters ✓ Very fast delivery because only door and back wall must be supplemented ✓ Low-cost ✓ Low-weight ✓ Low desorption of the aluminium, therefore also suitable for high vacuum ✓ Excellent thermal conduction ✓ Highly clean processes possible, e.g. in the semiconductor field ✓ Easy operation ✓ Easy attachment to the existing division bars Vacuum chamber specifications Internal dimensions Length: up to 3000 mm (standard: 625 mm) Width: 400 mm Height: 600 mm Front panel (optional): 16 U (1 U = 44.45 mm) Connections 1 x KF 16 7 x KF 40 Additional flanges possible in any position

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

The Vacuum Chamber VC P110x120 is made of a unique, flexible chamber system based on extruded aluminium profiles. The three meter long profiles are cut to the desired length and equipped with a bolted rear wall and a door. Slits are provided in the side walls of the profile for easy insertion of the product carriers. ✓ Flexible length of max. 3 meters ✓ Very fast delivery because only door and back wall must be supplemented ✓ Low-cost ✓ Low-weight ✓ Low desorption of the aluminium, therefore also suitable for high vacuum ✓ Excellent thermal conduction ✓ Highly clean processes possible, e.g. in the semiconductor field ✓ Easy operation ✓ Easy attachment to the existing division bars Vacuum chamber specifications Internal dimensions Length: up to 3000 mm (standard: 300 mm, 600 mm) Width: 110 mm Height: 120 mm Front panel (optional): 5 U (1 U = 44.45 mm) Connections 3 x KF 16 Zusätzliche Flansche in beliebiger Position möglich

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker Temperature Uniformity Survey (TUS) System from Fluke Process Instruments features the choice of data logger (TP6 or XDL12), choice of thermal barrier (TB45 or TB46), thermocouples and our intuitive Temperature Uniformity Survey (TUS) Insight™ Software package to perform accurate in-process product thermal profiling while verifying conformity to all required specifications, including the AMS2750 standard. Data Loggers The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections. Available in 10 and 20 channel configurations and two case styles Water resistant (IP67 rated) Communication via USB or Bluetooth

Request for a quote

BORSIG GMBH

Germany

Reducing energy, saving resources and safe processing have high priority in the chemical and petrochemical industry today. Our advanced liquid separation technologies are targeted to treat hydrocarbon based or solvent containing process streams and provide valuable tools for process intensification. Typically organic liquid streams are processed by conventional thermal unit operations that consume high amounts of energy, operate at high temperatures and/or require additional chemicals for efficient separation. Our membrane based solutions offer potent alternatives or additions for new processes and a valuable tool for the retrofit of existing unit operations. Our product range: - BORSIG Organic solvent nanofiltration - BORSIG Pervaporation - BORSIG Process development services

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

The Vacuum Chamber VC P150x160 is made of a unique, flexible chamber system based on extruded aluminium profiles. The three meter long profiles are cut to the desired length and equipped with a bolted rear wall and a door. Slits are provided in the side walls of the profile for easy insertion of the product carriers. ✓ Flexible length of max. 3 meters ✓ Very fast delivery because only door and back wall must be supplemented ✓ Low-cost ✓ Low-weight ✓ Low desorption of the aluminium, therefore also suitable for high vacuum ✓ Excellent thermal conduction ✓ Highly clean processes possible, e.g. in the semiconductor field ✓ Easy operation ✓ Easy attachment to the existing division bars Vacuum chamber specifications Internal dimensions Length: up to 3000 mm (standard: 325 mm, 600 mm) Width: 150 mm Height: 160 mm Front panel (optional): 6 U (1 U = 44.45 mm) Connections 4 x KF 16 1 x KF 40 Additional flanges possible in any position

Request for a quote

COLORPLASTICCHEMIE ALBERT SCHLEBERGER GMBH

Germany

The importance of additives. Behind the Color Masterbatch, additives are often regarded as “colorless” companion. However, their significance is far more substantial. Additives can have a decisive impact on product manufacturing and product life cycles. Optimise manufacturing processes. In the manufacturing process, additives are important. As required, cavities can be filled more easily, for example, in the injection molding process, parts can be removed from the molds or deposits can be avoided. The profitability of the production process can also be decisively improved: additives can minimize cycle times or reduce processing temperatures. We would like to inform you about the scope for optimising your production processes. Add more values. In addition, additives protect thermoplasts and generate additional properties. Thus antioxidants, both during the thermal forming process and in the application, enable the resistance of the polymer against destructive temperature

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

High performance cartridges and heating elements are excellently suited to direct heating of all kinds of tools. Area, ring and barrel heaters are suitable for heating boilers and moulds, tools, die plates, machine parts and a range of other purposes. They can be manufactured individually to size, voltage and output specifically for your application. High performance cartridges are suitable for tool heating in the many different fields in which a specific compatible operating temperature is required. High performance cartridges are essential in the thermal machining process field. High surface loadings facilitate a correspondingly high performance in a small installation area, at operating temperatures of up to 750°C at the heating cartridge jacket. We produce diameters between 6 mm and 45 mm to order. Different types of feed also allow high performance cartridges to be matched to the relevant installation situation.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

The Vacuum Chamber VC P572X125 is made of a unique, flexible chamber system based on extruded aluminium profiles. The three meter long profiles are cut to the desired length and equipped with a bolted rear wall and a door. ✓ Flexible length of max. 3 meters ✓ Very fast delivery because only door and back wall must be supplemented ✓ Low-cost ✓ Low-weight ✓ Low desorption of the aluminium, therefore also suitable for high vacuum ✓ Excellent thermal conduction ✓ Highly clean processes possible, e.g. in the semiconductor field ✓ Easy operation ✓ Easy attachment to the existing division bars Vacuum chamber specifications Internal dimensions Length: up to 3000 mm (standard: 300 mm, 650 mm) Width: 572 mm Height: 125 mm Connections 1 x KF 16 4 x KF 40 Additional flanges possible in any position

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

TIM thermal imaging cameras are designed for non-contact measurement of surface temperatures from -20 °C to 1900 °C. They enable efficient monitoring and control of temperature-critical processes both with low temperatures (e.g. in cooling chains) and with very high temperatures (e.g. in glass and metal processing). Their high thermal sensitivity makes these infrared cameras ideally suitable for precise and dynamic tasks. Different performance classes enable a suitable model to be selected for every application. The camera is connected via a USB interface, which also supplies the power.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Heating bands are the ideal solution for the heating of tubes an cylinders. Mica band heaters, frequently used as nozzle heaters, are made with a plastic-tight stainless steel casing. Such mica heating bands are in many dimension available from stock. The Ceramic heating band type is suitable specially for applications with high watt density and therefore for higher temperatures. Ceramic band heaters, also known as ceramic ring heaters or cylindrical ceramic sectional heaters, are attached to the contact surface by means of a clamping mechanism. A preferred field of use for ceramic band heaters is the heating of plasticising cylinders, bushings and nozzles of injection moulding machines and screw barrels of extrusion machines. For thermal optimization and process control ceramic band heaters can also be offered with insulation jackets or air cooling.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

The Vacuum Chamber VC P240X240 is made of a unique, flexible chamber system based on extruded aluminium profiles. The three meter long profiles are cut to the desired length and equipped with a bolted rear wall and a door. Slits are provided in the side walls of the profile for easy insertion of the product carriers. ✓ Flexible length of max. 3 meters ✓ Very fast delivery because only door and back wall must be supplemented ✓ Low-cost ✓ Low-weight ✓ Low desorption of the aluminium, therefore also suitable for high vacuum ✓ Excellent thermal conduction ✓ Highly clean processes possible, e.g. in the semiconductor field ✓ Easy operation ✓ Easy attachment to the existing division bars Vacuum chamber specifications Internal dimensions Length: up to 3000 mm (standard: 420 mm, 600 mm) Width: 240 mm Height: 240 mm Front panel (optional): 8 U (1 U = 44.45 mm) Connections 2 x KF 16 3 x KF 40 Additional flanges possible in any position

Request for a quote

ESTIMET SP Z O.O.

Poland

Laser welding is an advanced material joining technology that has found its way into a variety of industries. The process involves the use of a laser beam to melt and join materials, making it possible to precisely and effectively join parts with different properties. We provide professional laser welding services using a world-class FANUCI 4.0 PRO GenX handheld laser welding machine! This is a 4th generation laser welder and is characterized primarily by: - many times increased welding speed - excellent aesthetics of welds, requiring no further processing - no thermal deformation - deep penetration, guaranteeing the strength of the weld - excellent quality and precision of welds - working with a wide range of materials and thicknesses - joining of various materials

Request for a quoteResults for

Thermal processing - Import exportNumber of results

99 ProductsCountries

Category

- High-vacuum photo-cells (7)

- Infrared tubes (4)

- Temperature sensing devices (4)

- Cutting - steels and metals (3)

- Façade work contractors (3)

- Heat treatment furnaces (3)

- Industrial furnaces (3)

- Laser - cutting and welding machines (3)

- Olive oil (3)

- Boilers, industrial (2)

- Cutting - machine tools (2)

- Measurement - Equipment & Instruments (2)

- Organic food (2)

- Thermal insulation materials (2)

- Water extraction - systems and equipment (2)

- Air purification - equipment and systems (1)

- Aluminium sheets and bands (1)

- Automation - systems and equipment (1)

- Blast cleaning equipment (1)

- Casting, steel (1)