- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermosetting processing

Results for

Thermosetting processing - Import export

JOST CHEMICALS GMBH

Germany

Aqua Release 470 is a water-based, semi-permanent release agent and mold sealer in the field of thermoset processing, but especially for molds with highly porous surfaces. It can be used for castable or spreadable polyester-, epoxy-, phenolic and DCPD- resins. The operating temperature range of Aqua Release 470 is between room-temperature and +150°C.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers PAI sheets from different PAI types, Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF), where each type is best suitable for a specific application. The unique performance of polyamide-imide (PAI) is the result of being transformed from a thermoplastic to a cross-linked thermoset during an extended curing process. Our PAI is processed by experienced engineers and offeres the best possible values a PAI product can have and it is suitable for many applications, such as gears, rollers, plasma chamber hardware and wafer contact fixtures.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers PAI tubes from different PAI types, Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF), where each type is best suitable for a specific application. The unique performance of polyamide-imide (PAI) is the result of being transformed from a thermoplastic to a cross-linked thermoset during an extended curing process. Our PAI is processed by experienced engineers and offeres the best possible values a PAI product can have and it's suitable for many applications as gears, rollers, plasma chamber hardware and wafer contact fixtures.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers PAI rods from different PAI types, Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF), where each type is best suitable for a specific application. The unique performance of polyamide-imide (PAI) is the result of being transformed from a thermoplastic to a cross-linked thermoset during an extended curing process. Our PAI is processed by experienced engineers and offeres the best possible values a PAI product can have and it is suitable for many applications as gears, rollers, plasma chamber hardware and wafer contact fixtures.

Request for a quote

BIEGLO GMBH

Germany

Polyamide-imide (PAI), also known as the brand Torlon® comes in different grades and different shapes. PAI is known to be the highest performing meltable thermoplastic in terms of temperature resistance, chemical resistance and mechanical stress. BIEGLO offers PAI semi finished products, such as rods, tubes and sheets from different PAI types: Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF). Its mechanical strength at 205°C outperforms many engineering plastics at room temperature. The unique performance of Polyamide-imide (PAI) is the result of being transformed from a thermoplastic to a cross-linked thermoset during an extended curing process. Our PAI is processed by experienced engineers and offeres the best possible values a PAI product can have. It is suitable for many applications, such as gears, rollers, plasma chamber hardware and wafer contact fixtures.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JOST CHEMICALS GMBH

Germany

Treil Part 310 is a semi-permanent release agent in the field of thermoset processing, which allows multiple demoldings. It can be used for all types of resin and all kinds of processing, but especially for molds with highly porous surfaces. The operating temperature range of Treil Part 310 is between room-temperature and +475°C. Processed correctly, Treil Part 310 will leave a high gloss surface.

Request for a quote

JOST CHEMICALS GMBH

Germany

Spacewax 300 is a release agent in the field of thermoset processing. It can be used for castable or spreadable polyester-, epoxy- and DCPD- resins. The operating temperature range of Spacewax 300 is between room-temperature and +140°C. Processed correctly, Spacewax 300 will leave a high gloss surface.

Request for a quote

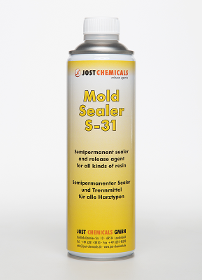

JOST CHEMICALS GMBH

Germany

Mold Sealer S-31 is a semi-permanent mold sealer in the field of thermoset processing. It can be used for all types of resin and all kinds of processing, but especially for molds with highly porous surfaces. The operating temperature range of Mold Sealer S-31 is between room-temperature and +475°C. Processed correctly, Mold Sealer S-31 will leave a high gloss surface.

Request for a quote

JOST CHEMICALS GMBH

Germany

HMC 180 is a cleaner for high tempered molds (above 60°C up to 180°C). Tenacious stains like baked-on residues, decomposed polymers and other contaminations can be removed easily. HMC 180 does not evaporate. To remove the dissolved residues a post-treatment with a quick cleaner (e.g.: fluid 010) is necessary.

Request for a quote

JOST CHEMICALS GMBH

Germany

Spacewax Sealer is a wax-based mold sealer and release agent in the field of thermoset processing. It can be used for castable or spreadable polyester-, epoxy- and DCPD- resins. The operating temperature range of Spacewax Sealer is between room-temperature and +200°C. Processed correctly, Spacewax Sealer will leave a high gloss surface.

Request for a quote

HEXPOL TPE GMBH

Germany

We have engineered a range of TPE compounds specifically designed to address the requirements for automotive mats - the Dryflex AM range. These materials combine the performance of thermoset rubbers with the processability of plastics. Applications for Dryflex AM materials include floor mats, trunk liners, coin mats, fascia mats and trim. For automotive floor mats the materials needs to have high scratch and abrasion resistance. It is also critical that the material is non-slip, even when wet. The material structure of Dryflex AM compounds produces the surface finish and high friction required. Dryflex AM materials are low odour and fogging. They require no vulcanisation and are 100% recyclable during production, making them easier to process than vulcanised EPDM with fewer steps. This means less energy is used and production is faster and more cost-efficient. Benefits of Dryflex AM TPEs Low odour Low fogging Lightweight 100% recyclable - 0% waste Easy to process with short cycle tim

Request for a quoteResults for

Thermosetting processing - Import exportNumber of results

12 ProductsCountries

Company type