- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cocoa and chocolate - machines and equipment

Results for

Cocoa and chocolate - machines and equipment - Import export

ALKE MACHINERY ENGINEERING

Turkey

Using our equipment for chocolate production you can ; To produce a wide range of chocolate types in an one production line, Chocolate production in different colors and shapes, switch quickly from one product to another, To expand the diversity of the masses with each other and with wafer, cookies and other combinations by increasing the variety of forms, making filling and confectionery,Any mass can be used: chocolate, caramel, praline masses, nougat, halva, marzipan, dried fruits, fondant, soufflé, marmalade etc. Almost completely free from manual labor.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

We produce enrobing machines of various capacities (pump or disk). The machines are adapted to work with natural chocolate or compound chocolate. Different belt widths on request. Detachable chocolate reservoir makes it easy to coat products in two different colors. (optional) Electrical panel on chocolate coating machine allows to adjust heat control, band speed control, thickness of chocolate coating and vibration Complete, bottom or top coating of the products.

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Precision depositing automatic weight adjustment (+/- 0,005) Piston drivers : Servo motor Control : PLC Touchscreen control panel Depositing speed : 8-10 moulds/min. for 2500kg blocks 4-5 moulds/min. for 5000kg blocks Capacity : 1200-1500 Kg/Hour Mould Dimensions : 400x300x50 mm Loose Mould System(without mould break) De-moulding : With Robot (product output direction and angle adjustable) Cooling Capacity : 90.000 kcal/hour Cooling Tunnel : Tower type cooling Couverture Moulding Line (KDH – 750) Precision depositing automatic weight adjustment (+/- 0,005) Piston drivers : Servo motor Control : PLC Touchscreen control panel Depositing speed : 4-5 moulds/min. for 2500kg blocks 2-3 moulds/min. for 5000kg blocks Capacity : 600-750 Kg/Hour Mould Dimensions : 400x300x50 mm Loose Mould System(without mould break) De-moulding : With Robot (product output direction and angle adjustable) Cooling Capacity : 45.

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Enrobing Machines Alper enrober is made with belt width from 400 , 600 , 800 and 1000 mm and designed for all common enrobing tasks with tempered as well as non tempered chocolate. On the machine there are following possibilities of enrobing. – Enrober can make bottom enrobing , top enrobing and combined bottom and top enrobing Combined bottom and top enrobing. – Partial enrobing by separation of chocolate curtain, it can be decided which part or parts of articles to enrobe – Designed for three shift operation – Stainless steel construction – Including one hot water system – Height adjustable blower with calibrated adjustable nozzle – Including return pump (optional) Frequency controlled : – Chocolate supply pump – Wire mesh band – Blower speed – Shaking device – Licking rollers

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

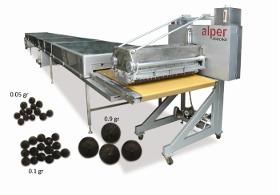

rop Line Chocolate drop size can be adjusted between 0.05 to 0.9 gr Each drop has its own piston Depositor has high precision since dosing is done by servo-motors. Depositor hopper is double jacketed and temperature controlled Depositor has agitator Easy cleaning PLC controlled Capacity: 33-600 Kg/hour

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Cooling Tunnel – Our cooling tunnel is used for cooling chocolate coated biscuits,jelly, nougat, fondant and similar products. – Belt widths 400,600, 800,1000, 1200 mm – Cooling unit is in the middle part of the tunnel. Two blowers supply the necessary air current. – Tunnel temperature is controlled by a digital thermostat. – Tunnel temperature can be down to 0°C. – Belt sped is controlled by electronic frequency drive. – Covers are insulted. – The tunnel can be cleaned by opening the top covers. – Tunnel has a automatic belt adjustment system. – Sharp edged infeed. – Tunnel has scrapers

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Tempering Machines Tempering is necessary in order to obtain a perfectly finished product. Five construction features enable perfect microcrystallization of the chocolate mass. – Long tempering sections – Large cooling surfaces – Turbulent mixing – Cooling time – Accurate temperature control ATM temepring machines meets these requirements. Final product has these characteristics: – Unique gloss – Fine grained and dense structure – Extended shelf -life – Crispy break – Short cooling time – Maximum contraction

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Wafer Cream Line

Request for a quoteResults for

Cocoa and chocolate - machines and equipment - Import exportNumber of results

11 ProductsCountries

Company type