- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- concrete products

Results for

Concrete products - Import export

TEMAS GROUP EXPORT PARTNERS

Turkey

MUSTANOGLU CONCRETE PUMP Pi 140-47-ZX Truck Mounted Concrete Pump is a highly sought-after model in the world of concrete pumping. Its popularity is particularly notable in large-scale projects due to its impressive concrete capacity of 140m³ per hour and 47m boom, allowing it to pour concrete up to 42m horizontally. The 140-47 model comes equipped with 5 booms and is designed with an S leg and R boom type. Production is customizable to suit various foot types as per your requirements. Additionally, the Pi 130-37-S is available. The 130-30ZX truck-mounted concrete pump is specifically designed for projects that demand work in tight spaces and call for rapid concrete pouring. With a concrete capacity of 130 cubic meters per hour and a 30-meter boom, it can pour concrete horizontally up to 25 meters. The 130-30 model, featuring an X-foot and Z-boom type, is fitted with 4 booms. Thanks to its small size, this concrete pump can be easily maneuvered in tight spaces and reach distant areas.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 120 m3/h mobile portable concrete batching plant is a versatile, high-capacity, on-site concrete-production facility; it can be reconfigured to cater to medium or large construction projects. These mobile plants are capable of producing 120 cubic meters of concrete per hour and will, therefore, cater to big concrete needs efficiently. The plant is flexible and easily transported to any site location, providing a prompt installation facility and concrete supply as per the demand requirements of the project. Thus, a mobile portable batching plant of 120m3/hour, its aggregate storage bins, cement silos, mixer unit, and control system create a reliable and flexible solution for construction projects that will require a high level of concrete volume. This latest type of mobile portable batching plant with a capacity of up to 120 m3/h can perform big and medium construction of infrastructural, commercial, and industrial projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A mobile concrete batching plant is a facility for concrete production that is portable and flexible in nature. The plant is designed in a way that it can be transferred with ease to and erected at various sites of construction so that concrete production can be done on site. Mobile batching plants are ideal for projects in which a frequent shift of construction sites or space constraints for a permanent stationary plant is required. This makes them flexible in terms of capacity and easily deployable to various locations for the fulfillment of various project requirements. Mobile concrete batching plants usually come in relatively small sizes, hence allow easy transportation using trailers or mobile plant units. Even for high-quality concrete mixtures, these plants are best suited for making concrete efficiently. With this, it is a very flexible solution to be used wherever a fast concrete supply is required.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A concrete production facility is a dry type where no water takes part in the mixing. In this type, water is not used for casting the mix. At this point in time, unlike the traditional concrete batching plants allowing the water to mix the materials, dry-type plants include mixing components like cement, aggregates, and admixtures without water in the mix. This type of batching plant is specially designed for the production of mixes by mixing all dry components and subsequently adding water in the final stages of the mixing cycle. Conditions under which concrete batching plants would be preferred include: nature of job, scarcity of water, restriction of water by local authority for environmental reasons, and transportation and storage difficulties in wet materials. In this sense, the installation of dry mixes along with a water metering system brings the most sustainable and efficient way of the concrete production process.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With its high capacity, the 100 m3/h capacity Dry Type Plant will be able to deliver large volumes of concrete without water in the mix in the beginning. These plants are very efficient in mixing dry ingredients like cement, aggregates, and other admixtures to produce a homogeneous and prime quality concrete mixture. This makes it the right plant to be used for large construction projects that are in dire need of a high output of concrete production. The facility provides accurate weighing and dispensing for dry materials into the batching system in a manner that ensures the correct caliber of aggregates and other components of concrete, hence consistent and reliable concrete production. Water is introduced to the mixtures only in the final mix, starting the cement hydration and yielding a well-mixed mixture suited for many and diverse varieties of construction applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 30m3/hr dry type concrete batching plant is a compact and an effective means of concrete production that does not utilize water in the main mixing process. A 30 cubic metres per hour production plant of this type is intended to deliver moderate volumes of quality concrete mixes used for small to medium scale construction projects. Unlike the traditional wet mix plants, which use water throughout the mixing cycle, a dry type plant produces concrete by mixing dry components such as cement, aggregates, and admixtures in exact proportions. Water is introduced at the very end of the mixing, so the plant takes water in small quantities and offers a sustainable and green solution for concrete production as a whole, thus suitable for areas with little water available and tasks where water is crucial.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A mobile concrete batching plant is a facility for concrete production that is portable and flexible in nature. The plant is designed in a way that it can be transferred with ease to and erected at various sites of construction so that concrete production can be done on site. Mobile batching plants are ideal for projects in which a frequent shift of construction sites or space constraints for a permanent stationary plant is required. This makes them flexible in terms of capacity and easily deployable to various locations for the fulfillment of various project requirements. Mobile concrete batching plants usually come in relatively small sizes, hence allow easy transportation using trailers or mobile plant units. Even for high-quality concrete mixtures, these plants are best suited for making concrete efficiently. With this, it is a very flexible solution to be used wherever a fast concrete supply is required.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A compact batching plant or mini batching plant is a smaller version of the conventional concrete batching plant made for projects having space and/or smaller concrete production requirements. Normally the setting is mobile with a tiny footprint, which is ideal for urban applications, renovation projects, or small construction sites where space is a major issue. The compact batching plants, ideally designed for portability, incorporate four aggregate bins, specially configured cement silos, a single shaft mixer, and a control system for suitable and accurate batching and homogenous mixing of concrete on the project site. Its compact design further allows easy transfer across sites and quick installation, thereby ensuring flexibility and convenience in concrete production for any particular construction application.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 100 tons horizontal type cement silo is a type of a structure constructed for holding a larger amount of cement in a horizontal way. These kinds of silos are used in construction work, concrete production plants, and a few other industrial applications that require storing large quantities of cement. The 100-ton capacity provides ample storage space for cement, ensuring that a constant and sufficient supply is maintained for construction. This silo has a horizontal layout, and within the small space it occupies, it serves its loading and offloading operation with a lot of ease. Considered to have such a big capacity, the Horizontal Type Cement Silo stands at 100 tons, since that is what the most silos available in the market are offering.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 25-ton Horizontal Type Cement Silo is a special storage container used for storing as much as 25 tons of loose cement positioned horizontally. Generally, it is used at construction sites, concrete batching plants, and other industrial plants where a constant supply of cement is required for continuous concrete production. The horizontal design allows for easy loading and offloading of cement. In fact, access to the stored material is easily made at ground level. Normally made of rigid material such as steel, these silos are sturdy and reliable, offering safety in storage while the cement is being protected from outside influences. The Horizontal Type Cement Silo, for example, is endowed with a capacity of 25 tonnes, amply suitable for medium and large construction works where this type of cement is in great demand.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 300-ton bolted-type cement silo is a special storage container that can contain up to 300 tons of bulk cement or anything else similar to it, in the powdered form, basically for the construction and industrial tools. These silos are very crucial elements in concrete batching plants, construction sites, manufacturing facilities, or any other place where great quantities of cement should be stored properly and easily accessible for production processes. Made of strong construction materials like steel, this 300-ton cement silo provides for safe and reliable storage of this vital construction material, ensuring the integrity and quality of the cement is maintained. A 300-ton silo holds a lot of product, providing a huge reservoir of cement on-site to keep concrete production, construction, or manufacturing running at a continuous flow.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With a more descriptive name, single shaft concrete mixers belong to the class of sturdy and powerful machines in the construction circles, used for mixing concrete ingredients. As with the name, the mixers have a single horizontal shaft, equipped with a set of mixing blades or paddles on it. The shaft rotates at high speed levels, which ensures the ingredients of cement, water, aggregates, and other additives mix properly to gain a uniform mixture of concrete. Single shaft concrete mixers have been very popular due to their rapid mixing times and ability to handle a large range of mixes in various concrete consistencies, ranging from fluid to stiff. These mixers have found wide applicability in projects where high-quality and consistent concrete is in demand; these include infrastructure development, building construction, and precast concrete production.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PAC 45m3/h Ant Site Type Plant is a concrete batching plant with a specified on-site production of concrete at 45 cubic meters per hour, with the ability to mix dry constituents like aggregate, cement, water, and admixture. The goal is to get a homogeneous concrete mixture right at the construction site. The plant is described as "Ant Site Type" to mean that it can be transferred and carried to any site, hence giving the construction crew the freedom to produce concrete at any place within the job site. Due to its high output capacity of 45 cubic meters of concrete per hour, the PAC 45m3/h Ant Site Type Plant will be highly effective for medium and larger-sized projects, where a large volume of concrete production is required on site in order to get the work done in an effective and efficient manner. PAC 45m3/h Ant Site Type Plant goes on with a continuous process of metering, mixing, and controlling the ingredients for the required output of concrete.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

PAC 30m3/h Ant Site Type Plant is a particular type of concrete batching plant, ideally designed for on-site concrete production, with a production capacity of 30 cubic meters per hour. These plants are characterized by compactness, portability, and efficiency and are, therefore, fit for small and medium-scale construction works under little space. "Ant Site Type" refers to the ability to be readily transported and laid at construction sites directly, thereby facilitating convenience of making concrete on the spot. Below are usually standard components that a PAC 30m3/h Ant Site Type Plant includes: aggregate bins which have different types of aggregates, cement silos which are for bulk cement storage, mixing unit in which the materials are blended, water dosing system having the accurate quantities of water, and a control panel used for monitoring and managing the batching. This plant offers an alternative to flexible projects requiring the production of concrete on-site

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Compact Sand Washing Plants are small, specifically designed plants developed for the effective cleaning and separation of sand particles in industrial applications. Most of the plants consist of a combination of equipment, including a sand washer, dewatering screen, hydrocyclones, and fine material washers, all integrated into one compact and mobile unit. Compact Sand Washing Plants are mainly designed to remove impurities, silt, and contaminants from sand to leave the final product clean, well-graded, and fit for use in construction, concrete production, and other industrial procedures. These plants integrate several washing and screening mechanisms in an integrated compact design, ensuring high effectiveness in washing and dewatering sand while guaranteeing better output quality at space and operationally lower footprints.

Request for a quote

ISONEM BOYA VE YALITIM TEKNOLOJILERI INS.SAN.TIC.A.S.

Turkey

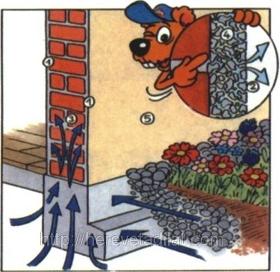

ISONEM MS 20 is a specially produced plaster to ensure the treatment of humid and salt damaged walls. The walls absorb the water involving various salts such as the carbonate, sulphate and nitrate existing in the soil during the weather conditions at the seasons through the capillary canals and gaps. Then, such waters absorbed from the soil vaporize and the rest is seen as the humid occurrence and accumulated salts on the walls, in the course of time, such salts accumulate on the wall and inside the plaster so when they re-contact with the humid, they damage walls. To solve such problem, ISONEM MS 20 Capillary Plaster is used it ensures the water to be vaporized quickly without leaving any humid mark. ISONEM MS 20 has the micro spaces enabling to store the salts as well as to prevent the expansion. Thanks to such spaces, it is prevented the salts to damage the plaster and the paint. ISONEM MS 20 has the hydrophobic structure.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UTK Series Tertiary Impact Crushers are preferred at crushing for medium and low hardness, mostly at tertiary level and can be used as secondary crushers depending on the hardness and feeding size. It produces very fine aggregate which is required for asphalt and concrete production. The rotor can rotate in both directions. The direction of rotation is bi-directional, allowing product to be received in two different gradations without setting changes. In addition, it provides longer life since there will be bi-directional wear on rotor hammers. According to the design of the facility, they can be manufactured as mobile, with fixed steel legs, with fixed concrete legs, with fixed skid chassis.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UMMANMAK

Turkey

UMMAN Concrete Recycling System aims to recycle the waste concrete formed in the concrete plant by washing the aggregate and cement so that it can be used in the concrete plant again. The Concrete Recycling Unit recycles the waste concrete, providing great benefits in terms of cost and preventing environmental pollution. ENVIRONMENTALLY FRIENDLY In our period when the protection of the environment is much more important, minimizing the environmental impact and producing harmless to the nature have become a necessity for concrete production plant. Waste concrete left to nature freezes, pollutes underground resources and harms the environment and living things by adversely affecting groundwater. The Recycling Unit is of great benefit to the environment as it recycles the waste concrete into production.

Request for a quote

UMMANMAK

Turkey

UMMAN Twin Shaft mixers, which are offered in a wide capacity range from 1 m³ concrete to 4 m³ concrete production, optionally such as 2 or more discharge caps, special design for RCC production, high pressure mixer interior washing, humidity and temperature sensor, etc. according to the project and application requirements. equipment can be installed. It offers comprehensive and wide-ranging high-performance solutions suitable for all concrete needs of its customers. Our Umix Ts twinshaft Mixers have two horizontally mounted mixer shafts and are the ideal mixer type in terms of concrete mixing time and quality. It is preferred by companies that want medium and high capacity.

Request for a quote

UMMANMAK

Turkey

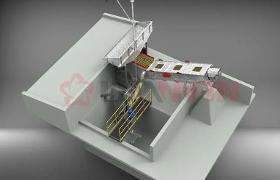

USC 120 Stationary Concrete Batching Plants, 3 m³ plant circulated with Twin Shaft Mixer USC120 Stationary Concrete Batching Plant is an ideal option for high-capacity serial concrete and ready mixed concrete production. It is a preferred model in metropolitan cities and large construction areas. We aim to reduce the infrastructure expenses by %90 by minimizing the ground (field concrete) expenses in the installation of concrete plants.

Request for a quote

AS RUBBER

Turkey

Our company specializes in rubber products and concrete pumps.Our pistons have 20% longer service life than the other products.

Request for a quote

STANDART INSUALTION MATERIALS INC.

Turkey

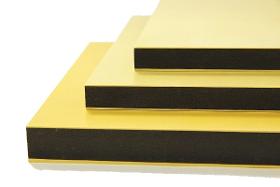

Pi Plak is most requested products for the fair-faced concrete formworks especially in floor-slab formwork where more reusing is required Being an eco-friendly and highly resistant; it resists to chemical reactions inside concrete and with its high reusing counts as being resistant to rubbing it proves its profitability more clearly. Pi Plak is among the most requested products for the fair-faced concrete form-works especially in floor-slab formwork in which more reusing is required. Pi Plak is eco-friendly and highly resistant; it has resistance to chemical reactions inside concrete and with its high reusing count it is a profitable alternative. In comparison to plywood, its not as pressure resistant but by narrowing purlin spacing fair-faced concrete can be achieved.

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1230 Concrete Pavers and Block Making Machine; It is a machine that works fully automatic. The movement of the machine is programmed the PLC microprocessor computer. By changing moulds all kinds of pavers stone , curbs, block and precast concrete elements such as grass pavers series can be produced in a serial way. 20cm block can be produced 12 units in one press with the machine,or 30 interlock stones can be produced in a press. Machine is able to produce the insulated block upon demand. Our company’s special production vibrator is used. Thus, it can produce smoothly and quickly. Pneumatic bellows cylinders are used in connection of the mold of the machine. In this way a more uniform vibration propagation in the mold is obtained. Other than the mold and the press, thin and the bold mortar sections are moved over the hard chromium-plated column mills as well.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

Our ZIM 820 machine is a mid-entry machine designed for the production of double-layer paving stones. The ZIM 820 stands out with its low energy consumption, wide choice of production and high return on investment. It can be used manually, semi-automatically and fully automatically if requested. Our machine, which can produce 8 concrete blocks or 20 concrete paverstones in one press, is designed to produce 1000 pallets per day. To facilitate this production and increase quality; It has many features such as internal shaking system in the mortar cart, driver-controlled vibration system, special balancing system on the upper mold, and a specially designed vibration table. We are using “ FULLDRIVE ” frequency controlled vibration systems in our machine. This helps the life cycle of vibration engines and also decreases the total electrical consumption of vibrators.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM T 1220 machine is designed to produce pipes. It uses forklifts to transport concrete pipes and it makes the production cycle shorter. Also it has uniqe specifications to increase production capacity, using life, products quality. This machine can produce pipes 300mm – 1200mm diameter and 1000mm – 2000mm height. The machine can be designed for producing single, double and triple pipe in a press. The vibration system of machine is controlled by frequency driver controll system. It does not need any mechanic settings. It can easily adjusted from operator pannel. The vibration system specially designed by our R&D team is used in our machines. The cooling of the vibrators are done by oil cycle system. There is a special unit for that cycling process. Oil flow is controlled by special sensors. Thanks to this technology our machines which have been working for many years without any problems, stand out with their low operating costs.

Request for a quote

PURIN POLYURETHANE

Turkey

Injection foams are liquid resins that can be injected into all gaps from capillary cracks to large cracks in concrete structures. It can be used in areas such as crack repair and building consolidation, especially in waterproofing, by converting from polyurethane liquid to solid by creating chemical reaction in seconds after injection process. Injection foams offer the possibility to apply in different forms for different purposes, from hard to very soft.

Request for a quote

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

Capacity: 100 LT/ minu. Dimensions: 110X70X80 (u.g.y) Weight Total: 70 kg Tank Capacity: 50 lt System: Air compressor foam nozzle and chassis Total power: 2 KW Energi: 220 W Control: Manuel

Request for a quote

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

POLIFIL: E.P.S Styrofoam granular mortar - concrete admixture It forms a bond between styrofoam granules and cement mortar. It creates air bubbles in the cement mortar accumulated in the gap between the granules and reduces the cement consumption. It provides good strength due to the crystallization in the inner wall of the cement mortar surrounding the air bubbles surface. Prepared with POLİFİL, Styrofoam Granulated concrete Breathable, Does not perspiration, Moisture-proof. It provides long-lasting concrete. Styrofoam Granulated Concrete Concrete Surface No dusting. Concrete, Concrete surface becomes hard and Strength. Styrofoam does not to the surface. There is no need to cover the screed surface with concrete. Ceramic, Tiles, Stone, Parquet Can be easily bonded. Styrofoam Concrete does not collapse under Heavy Load.

Request for a quote

ARTRA LIGHTWEIGHT CONCRETE TECHNOLOGIES

Turkey

GENFİL (Foam Agent) It is a high efficient, organic resin-based foam agent developed for the production of lightweight concrete and lightweight structural elements in the construction sector. The foam material is composed of antibacterial, enzyme-based, active proteins. It is organic, does not harm nature, is not harmful to human health.

Request for a quoteResults for

Concrete products - Import exportNumber of results

39 ProductsCountries

Category

- Concrete preparing - machinery and equipment (17)

- Concrete mixers (11)

- Concrete blocks (7)

- Brick-making - machinery and equipment (6)

- Concrete pumps (2)

- Tile-making - machinery and equipment (2)

- Concrete constructions (1)

- Construction - Machines & Equipment (1)

- Crushing and grinding machinery (1)

- Insulation - injection materials (1)

- Natural resins (1)

- Panels, veneered and plywood (1)

- Panels, wood (1)

- Plaster and plaster products (1)

- Substations, high-voltage (1)