- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial equipment

Results for

Industrial equipment - Import export

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

The homogenizer is used in food, cosmetic, pharmaceutical, chemical and other industries, for the production of ketchup, mayonnaise, creams, gels, pastes, ointments, household chemicals, varnish-and-paint products, pharmaceutical substances and other emulsions and suspensions, which do not divide into layers, also for emulsions of high dispersing.The installa-tion is made in the form of a vertically located reactor with a volume from 100 to 1000 liters with a conical bottom. The reactor is equipped with a heat exchange water jacket with a block of electric heating elements, as well as a frame stirrer or blade type mixer, with a speed of 56 rpm. The homogenizer is equipped with a homogenizer pump and a loading device for dry products. The heat exchanger jacket can also be used to cool the finished mixture. It is possible to supplement an installation with a fat's melting down barrel and with a dispersing device. It is possible to ensure the vacuumization of the product in the reactor.

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

Horizontal bead mill with a working chamber volume of 20 or 50 liters. Engine power - 22 or 45 kW. Vertical bead mill, with a working chamber volume of 3, 10, 20, 50, 75 and 100 liters. Engine power - from 4 to 55 kW. Submersible bead mill (basket mill) with a working chamber volume of 10 or 20 liters. Designed for vessels up to 250 and up to 500 liters. Electrical equipment is performed in general industrial or explosion proof versions.

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

Vacuum dissolver with one, two or three shafts. It is intended for vessels with a volume – from 50 to 1200 liters. It is manufactured on the basis of the above mentioned dispersers: near wall (floor) dissolver, compact dissolver or dissolver with hydraulic lifting of the tool. Power of the main engine – from 3.0 to 55 kW, speed of main working shaft – from 100 to 1500 (3000) rpm. It is carried out in both, Ex and IP version, with one main working shaft (milling cutter), with two working shafts (milling cutter and slow-moving anchor agitator with elements cleaning walls of a vessel) or with three working shafts (a milling cutter, a slow-moving stirrer and a fast moving stirrer of butterfly type).

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

Stationary dissolvers, volume from 50 to 5000 liters. The power of the main electric motor is from 1.2 up to 150 kW. The rotational speed is adjustable from 100 to 1500 rpm. or from 100 to 3000 rpm., on legs or overpass, with weight equipment,etc. Can be equipped with various tools.

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

Dissolver, compact, with one or two shafts, for premises with a low ceiling. It is supplied with an electromechanical lifting of the tool. It is intended for vessels with a volume – from 30 to 500 liters. An electric motor’s power – from 2.2 kW to 11kW, the turnovers – from 100 to 1500 (3000) rpm, 380V. It is carried out in both, Ex and IP design. A milling cutter can be installed on one shaft and a stirrer of the required type can be installed on another shaft.It is possible to produce a dissolver, providing vacuum in the working area.

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

The dissolver is hydraulic, single-column, floor-mounted. We can offer such a machine with the power of the main engine (cutter) - from 7.5; up to 75.0 kW., 380 V. for replaceable vessels of 100 to 1500 liters. Electrical equipment can be made in a general industrial or explosion-proof design. The dissolver is equipped with a hydraulic drive for lifting the traverse, on which the shaft with the tool and the lid are mounted. All parts that are in contact with the product are made of food or technical stainless steel (customer's choice). Turnovers are regulated from 50 to 1500 rpm. (possibly from 50 to 3000 rpm) using a frequency converter. For more viscous products, it is possible to manufacture a dissolver with two or three working shafts, one of which will have a milling cutter, and the other will have a low-speed stirrer, for example, an anchor type with cleaning elements, and on the third - a high-speed stirrer.

Request for a quote

PLASMA COMPANY LLC

Ukraine

Mining machinery and equipment is mainly used for mining operations. But, at present, it is widely used not only in the mining industry but also in such industries as metallurgy, mechanical engineering, energy, chemical industry, etc. If we talk about the classification of mining equipment, it is divided into mine, quarry, mineral processing, and transport equipment. A list of the equipment used in the mining and mineral processing industry is extremely large, it is boring machines, machines, and systems for underground mining; mining systems and automatics; mining machines and systems for open mining operations; jetting means mining operations; transport machines; machine mine water, ventilation and compressed air systems; machine mine hoist and others. We manufacture: Electric Pulling Winches Electric Scraper Winches Bottom Dump Muck Cars Rocker Dump Muck Cars Air Mucking Machines Electric Mucking Machines

Request for a quote

PLASMA COMPANY LLC

Ukraine

Asynchronous AC motors are the most common form of motors which are used in everyday life from pumping water up the overhead tank to power plant boiler feed pumps. These motors are very flexible to use and match the load demand almost for everything. The most widely used Induction Motors are very important for many industries due to their load bearing capacity and flexibility. These motors, unlike synchronous motors, slip when compared to the stator current field. They are generally used for various types of pumps, compressors, and acts as prime movers for many types of machinery. Plasma Company, LLC offers a variety of components for the industrial equipment and machinery. Explosion proof electric motors are available for assembly of cranes, hoists, conveyors, pumps, ventilation equipment, hydraulic power packs, and other. Our application engineers will help select equipment for your specific application.

Request for a quote

KONTAKT LLC

Ukraine

Gas pressure regulators RD-M are designed to reduce and automatically maintain the gas pressure “after itself” at the set value. Gas pressure regulators of the RD-M type are used at the facilities for main gas pipelines: Gas distribution stations, Gas purification and dehydration installations, Compressor stations, Gas fields. Distinctive features of the RD-M regulator: Hydrate formation in the “seat-valve” contact zone does not affect the regulator operation. Tightness at full closing of the valve. Smooth regulation characteristics due to the use of an oil compensator. High accuracy of maintaining the set pressure. High maintainability (possibility to repair wearing parts without removing the regulator body from the reduction line). Possibility to automate the reduction process. Upper setting limit, MPa/(bar)-1.2/(12) or 4.0/(40) depending on the setting device. Lower setting limit, MPa/(bar)-0.15/(1.5) or 1.2/(12) depending on the setting device. More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

The main directions of our activity: Gas equipment for high pressure pipelines. We produce gas pressure regulators and setting devices, gas odorizing complexes, some equipment for CNG stations, shutoff valves and other products for the gas industry. Mining equipment such as components, control units and shutoff valves for operation in industrial complexes with hydraulic systems. Hydraulic lifting equipment: hydraulic supports and hydraulic cylinders. Non-standard equipment according to our customers’ design drawings. You can order equipment of any complexity and functionality from us. More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

AGRSM-1500 “Donbass” are automatic and automated gas distribution stations of small capacity, up to 2000 nm3/hour. The equipment can be ordered for installation at the operating gas distribution stations and gas supply to small settlements. Gas distribution stations are easy to maintain and operate. AGRSM-1500 provides the following main functions: Purification of gas from liquid droplets and mechanical impurities. Reduction of high gas pressure (Pin=1.2 MPa … 7.5 MPa) to the set average pressure (Pout= 0.3 MPa … 1.2 MPa) and its maintenance with a certain accuracy at changing of input pressure or gas flow rate. Manual or automatic gas odorization in proportion to the gas flow rate. Gas consumption measurement with multi-day recording. Manual control of the AGRSM technological equipment operation modes. Sending of alarm signals to the operator or dispatcher when the operation modes are violated. Automatic control of the switching unit. More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

The automatic complex of gas odorization KCOG-4K is designed for the dosed supply of odorant, ethyl mercaptan – C2H5SH or mixture of mercaptans to the natural gas flow supplied to consumers to provide odorization for timely leakage detection. The complex KCOG-4K is used as an automatic gas odorizing unit at gas distribution stations (GDS) for enterprises and settlements, as well as for CNG filling stations. The KSOG-4K complex provides the required degree of odorization for all types of the odorant, from 5 to 32 g/1000 m. According to individual requirements, the volume of odorant can be changed depending on the customer’s needs. The set of the KSOG-4K complex is subject to mandatory agreement with the Customer before delivery and can be changed depending on the specific conditions of the facility operation. The KSOG-4K odorizing equipment of its own design by the Kontact LLC has all necessary authorization documents and Certificates. More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

The gas receiver units are special equipment for the CNG filling stations, manufactured exclusively according to the customer’s technical specifications and designed to expand the processing capabilities of the CNG filling stations. The following must be obligatorily agreed with the customer: Supporting metal construction of the cassette of cylinders. Piping design. The details of the distribution unit. Cylinders for the receiver units, as a rule, are provided by the customer, have a certificate of conformity and a registration certificate of the corresponding model. On delivery of the completed equipment to the customer, the Kontact LLC plant provides: Plant design tests. Assembly, adjustment and testing at the customer’s facility. More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

2GRP 10/0.002 gas regulation point is equipment for supplying natural gas of the required degree of purification and odorization from the main gas pipeline to an individual consumer. Main application: supply of the household natural gas to the operator’s house, which is a part of the GDS. Gas regulation point is designed in climatic modification “Y” category 3 according to GOST 15150-69. +45/-50 C. You can use 2GRP 10/0.002 gas regulating point as a farm GDS if you order an additional complete set of the counter and the system of automation and parameter control. 2GRP 10/0.002 gas regulation point of its own design by the Kontact LLC has all necessary authorization documents and Certificates. Input pressure, MPa/(bar) - 1,2/(12) to 10/(100). More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

Gas pressure regulators of the RDU-T type with a heat generator are designed for automatic regulation of gas pressure “after itself” of the set value at the facilities of high pressure gas pipelines. They are used at: Gas distribution stations. Gas purification and dehydration installations. Gas fields. Compressor stations, etc. The regulators are designed for operation at ambient temperatures from +50 C to -40 C and relative humidity up to 95% at a temperature of +35 C. Distinctive features of RDU-T regulators: The RDU-T regulators differ from the RDU regulators of the same class by the heating of the shut-off and regulating device in the zone of gas throttling using specially mounted heat generators which operate without an external energy source by taking a part of the kinetic and potential energy of the compressed main gas. The heating temperature is sufficient to prevent hydrate formation processes. More information on our website.

Request for a quote

KONTAKT LLC

Ukraine

The gas pressure regulator of the RTBK type is designed for automatic regulation of gas pressure “after itself” at the facilities of high pressure gas pipelines, such as gas distribution stations, gas treatment and dehydration plants, gas fields, compressor stations, etc. The operating medium is natural gas and other gases that are not aggressive to regulator materials. Inlet working pressure: from 12 to 100 bar Output working pressure: from 1 to 12 bar Depending on the order, the modular regulator of the RTBK type can include the following elements: General-purpose body based on which the modular type regulator is built. Active module. Monitor module. Built-in shut-off valve. Shut-off valve as a separate element connected in series with the regulator body. Noise reduction module. And other technical combinations of modules and components. More information on our website.

Request for a quote

AKTAPROM

Ukraine

We produce technical labels based upon anodized aluminum method for the greatest variety of industries and organizations. Our labels will help you to identify and promote your goods all over the market. We create product specifications upon requirements of our clients. We understand that every label logo should be unique one for our customers to get more advantages for their products distribution all over the world. Technical aluminum labels are widely used for sticking on different equipment and its separate parts, especially it concerns electrics and its different parts, so as in accordance with safety rules, oracal labels are prohibited. In case the equipment is operated under severe conditions: high temperatures, different acids, abrasives, constant UV rays etc., it is relevant to use wear-resisting labels based upon anodized aluminum Alumaproof technology.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MARIBELL TM

Ukraine

We've started production of Slush Syrups as it becomes popular every day. You can order: - Lemon - Strawberry - Peach - Mint - Cherry - Watermelon - Passion Fruit and others Packing: 1L plastic or 5L plastic, other packing by request We export worldwide. To know the price, please email: irina.syrup@gmail.com

Request for a quote

SPF SWEDA LTD

Ukraine

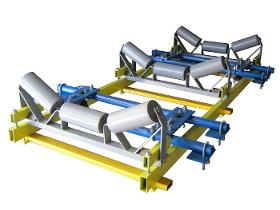

Automatic belt scales (belt weigher) SWEDA VK are designed for continuous measurement of the mass of bulk and lumpy materials transported by belt conveyors and indication on a digital display of the current conveyor performance and the value of the mass of weighed bulk and lumpy materials on a accrued total during commercial, accounting and technological operations. Features: - Accurate weighing and accounting of material in the flow (± 0,5%); - Measurement and indication of momentary сapacity; - Summation and indication of the total weight per shift, day, total; - Wide operating temperature range; - Possibility of calibration and verification without material overweight; - Modular construction, which makes it easy to transport and mount the scales directly at the enterprise; - Data output to a remote display and a computer as part of the process control system; - More than 1000 serial samples are in operation in 15 countries.

Request for a quote

SPF SWEDA LTD

Ukraine

The bag sewing line is designed to transport filled bags from the dispenser to the sewing machine and then move the sewn bags to the unloading point. Features: - High capacity of sewing (up to 600 bags/hour); - Modifications with different conveyor lengths from 2m to 5m; - Industrial sewing machine; - Adjusting the speed of the conveyor belt; - Height adjustment of the conveyor by means of supports; - Successful exploitation at more than 200 enterprises in different countries. More details about our weighing and packing equipment you can find on our site: www.sweda.com.ua/en We are in social networks: Facebook: https://www.facebook.com/SPFSwedaLtd Instagram: https://www.instagram.com/easyweighing/

Request for a quote

SPF SWEDA LTD

Ukraine

The Big-Bag packing machine SWEDA DWS-301-1000-1 is intended for batching bulk materials into super sacks (“Big-Bag”). The Big-Bag filling machine can be used for batching cereals, sugar, compound feed, mineral fertilizers, granules and other bulk materials. Features: -High capacity (15 bags per hour); -Stainless steel tract (optional); -Fan for blowing the bag eliminates spillage of the product; -Protection of the weighing platform from being hit by a loader; -Communication with the automated control system of the enterprise and the owner’s office; -There are no special requirements for operating conditions and staff; -Prompt mounting, adjusting and put into operation. More details about our weighing and packing equipment you can find on our site: www.sweda.com.ua/en We are in social networks: Facebook: https://www.facebook.com/SPFSwedaLtd Instagram: https://www.instagram.com/easyweighing/

Request for a quote

SPF SWEDA LTD

Ukraine

The Big-Bag packing machine SWEDA DWS-301-1000-1-P is intended for batching bulk materials into super sacks (“Big-Bag”). The Big-Bag filling machine can be used for batching cereals, sugar, compound feed, mineral fertilizers, granules and other bulk materials. The FIBC fiiling machine SWEDA DWS-301-1000-1-P is structurally different from the FIBC packing machine SWEDA DWS-301-1000-1 by the presence of additional units: a weighing belt conveyor (instead of a weighing platform), a storage belt conveyor and an overhead feed hopper. Features: -Increased capacity (up to 35 bags per hour); -Stainless steel tract (optional); -Fan for blowing the bag eliminates spillage of the product; -Automatic ejection of the straps and the removal of the bag from the batching area; -Communication with the automated control system of the enterprise and the owner’s office; -There are no special requirements for operating conditions and staff; -Prompt mounting, adjusting and put into operation.

Request for a quote

SPF SWEDA LTD

Ukraine

Open-mouth bag filling machine DWS-301-50-1 is intended for packing of free-flowing materials in open-mouth bags. By means of the bag packing machine SWEDA DWS-301-50-1 it is possible to pack up in sewing (open) bags (paper, polypropylene, jute) free-flowing products, including food. Long-term operating experience of bag filling machine SWEDA DWS-301 for packing of sugar, grains, seeds, cereals, granulated powders, pellets and other free-flowing substances and materials has confirmed it’s high accuracy and reliability. Features: - High capacity (up to 400 bags/hour) and batching accuracy (class 0.2); - Stainless steel tract with dust cover; - Work 24/7; - Possibility of communication with the automated control system of the enterprise and the owner’s office; - Easy to operate, without difficult settings and menus; - There are no special requirements for operating conditions and staff; - Operational mounting, adjustment and put into operation.

Request for a quote

JUKA-INVEST LTD

Ukraine

Our assortment includes the following ranges: -Display freezers with curved and flat glass sliding lids; -Display freezers of bonnet type; -Chest freezers with solid doors; -Scooping freezers for gelato; -Freezing and cooling upright cabinets with glass and solid door; -Gastronomic refrigerated showcases; -Pastry counters.

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Two-units brewhouse for 1000 litersBH-10001 pcs.22800,00 Roller malt mill 300 kg/hRM-3001 pcs.1340,00 Plate sanitary wort chiller for wort cooling HE-1000HE-10001 pcs.1680,00 CIP-station for tanks up to 1000 liters and beer kegsCIP100(2)-K1 pcs.3900,00 Beer Glycol Chiller for Fermentation Tanks Cooling CH-12CH-121 pcs.7860,00 Cost of base equipment:71880,00 € Additional equipment Hot water tank at 2000 litersHWT-20001 pcs.6100,00 Cold water tank at 2000 litersCWT-20001 pcs.6800,00 Cost of additional eqiupment:12900,00 € Cost of complete set:84780,00 € Electricity consumers: Two-units brewhouse – 64 kWt Roller malt mill – 1.5 kWt CIP-station – 6.1 kWt Beer Glycol Chiller – 4.5 kWt Hot water tank – 13 kWt

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Roller malt mill 150 kg/hRM-1501 pcs.990,00 Two-units brewhouse for 300 litersBH-3001 pcs.11100,00 CCT at 600 litersCCT-6007 pcs.3700,0025900,00 Plate sanitary wort chiller for wort cooling HE-300HE-3001 pcs.1110,00 CIP-station for tanks up to 600 liters and beer kegsCIP60(2)K1 pcs.3070,00 Beer Glycol Chiller for Fermentation Tanks Cooling CH-6CH-61 pcs.5610,00 Cost of base equipment:47780,00 € Additional equipment Hot water tank at 600 litersHWT-6001 pcs.3250,00 Cold water tank at 600 litersCWT-6001 pcs.3700,00 Cost of additional eqiupment:6950,00 € Cost of complete set:54730,00 € Electricity consumers: Roller malt mill – 1.5 kWt Two-units brewhouse – 23 kWt CIP-station – 3.8 kWt Beer Glycol Chiller – 3 kWt Hot water tank – 5 kWt

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Roller malt mill 150 kg/hRM-150 Two-units brewhouse for 300 litersBH-300 CCT at 300 litersCCT-300 Plate sanitary wort chiller for wort cooling HE-300HE-300. CIP-station for tanks up to 600 liters and beer kegsCIP60(2)K Beer Glycol Chiller for Fermentation Tanks Cooling CH-6CH-6 Cost of base equipment:41830,00 € Additional equipment Hot water tank at 600 litersHWT-600 Cold water tank at 600 litersCWT-600 Cost of additional eqiupment:6950,00 € Cost of complete set:48780,00 € Electricity consumers: Roller malt mill – 1.5 kWt Two-units brewhouse – 23 kWt CIP-station – 3.8 kWt Beer Glycol Chiller – 3 kWt Hot water tank – 5 kWt

Request for a quote

SPEKTRUM, LTD

Ukraine

Cherry pitting (destoning) machine PM-250 (200–300 kg/h) is designed to removing kernels out of fresh berries of cherry. We recommend you! Cherry pitting machine PM-250 is used in own production line for production of ecologically clean natural products under the trademark Spektrumix. Main technical data Capacity, kg/h: 200 - 300 Capacity (maximum), berries (pcs)/h: 720 Permissible dimension of berries, mm: 15 - 25 Operation speed, strokes per minute: 60 Number of drums, pcs: 2 Number of knives, pcs: 12 (6 + 6) Diameter of knives, mm: 7,8 Material of operating space: stainless steel for food industry, food grade plastic Electrical power, kW: 0,2 Supply voltage, V: 220, 1PH Dimensions (L x W x H), mm: 700 x 680 x 600 Net weight, kg: 48 Data 1. The equipment is certified — ISO-9001, СЕ, EAC, etc. 2. Warranty term for the equipment - 12 months. The actual price of the cherry pitter machine (seeds remover) from the manufacturer.

Request for a quote

ООО "СТС ТРЕЙД"

Ukraine

For the implementation of disinfection measures in preschool, school educational institutions; for preventive, current, final disinfection, sanitary and other premises, enterprises trade, in the agro-industrial complex, veterinary medicine, as well as in household, removal of unpleasant odors, for surface treatment, pipelines, tanks, tanks, pasteurization plants and other food industry equipment (dairy, meat, non-alcoholic beer, fatty, fish, semi-finished products, slaughterhouses and others), on poultry farms, livestock farms, as well as for the removal of persistent and problematic pollution in the HORECA area (in professional kitchens, hotels, restaurants, cinemas, shopping centers, swimming pools, children's health camps, recreation centers). Quickly kills bacteria, yeasts, molds, gram-positive and gram-negative microorganisms even at low concentrations funds.

Request for a quoteResults for

Industrial equipment - Import exportNumber of results

33 ProductsCountries

Company type

Category

- Food Industry - Machines & Equipment (10)

- Industrial valves, operating equipment (8)

- Chemical industry - machinery and equipment (6)

- Beverage industry - machinery and equipment (4)

- Paint mixers and grinding machines (4)

- Refrigeration plants and equipment, commercial and industrial (1)

- Cosmetics industry - machinery and equipment (1)

- Mining and quarrying - machinery and equipment (1)

- Beer (1)

- Detergents and soaps - professional (1)

- Electric motors - aC (1)

- Electric motors and parts (1)