- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding systems

Results for

Welding systems - Import export

RALF LANG MASCHINENBAU GMBH

Germany

Stainless steel system for cleanroom production with 400 W laser system Positioning the laser head using a 3-axis servo system Stainless steel lifting door with inspection window

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

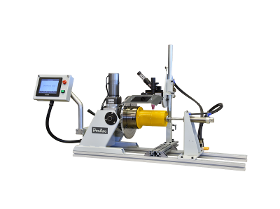

ProArc ServoArc PT-200s is ready for sell. It is a mini positioner that specially designed for automated welding. PT-200s adopts with servo motor and multi-functional CB-500 controller to provide the most stable rotation. It’s easy to build your own welding parameter library that significantly improves welding quality and increases production yield in a short time. • Excellent graphic user interface controller • Uses 20-bit servo motor to achieve 0.1° rotation accuracy • Speed of 0.01 ~ 30 rpm with constant torque & rotation stability • Tilting range from 0 ~ 120°, manual adjustment • Floor type structure for convenient loading/unloading of weldments - create welding flexibility • High frequency interference protection • Spindle through hole allows delivery of shield gas

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc PCW Precision Circumferential Welder provide all of the features necessary to position and rotate parts for circumferential welding. Advantage: 1. The extreme accuracy welding lathe with servo motor control for turntable and transverse carriage. 2. Allow unskilled people to get high welding quality and consistently production progress. 3. Designed to enable horizontal or vertical configuration for more flexible welding solution. 4. ProArc offers a user-friendly and intuitive controller interface that allows users to implement the system quickly. 5. ProArc designed AVC (option) Enable to set the parameter of AVC in the integrated controller. 6. Motorize carriage on X axis (option) Ball screw drive system with dual linear guide way. * Positioning accuracy is +- 0.01mm * Travel speed 1 ~ 10,000 mm/min 5. Maximum through hole for diameter 80mm. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

4 Major Advantage: 1. Cost effective and modular design.to increase welding productivity. 2. Set up with CB-107-1 Sequence controller : * User-friendly sequence controller. * Save 100 sets of programs * Even a non-experienced user can learn how to operate in few minutes. 3. High frequency protected 4. Suitable for different welding processes like TIG, MIG and plasma welding. 5. 2 year warranty *CE Conformity

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

Enhance your automated welding processes for inner, outer, circumferential and longitudinal welding applications with Key Plant column and boom welding manipulators. Key Plant column and boom manipulators are developed to upgrade your fabrication throughput, and augment the quality of your weld production. We supply machines for a range of manufacturing environments; from pipe fabrication shops to tanker assembly lines, Key Plant provide the best solution to suit your project requirements. Key Plant have built a portfolio of global leading column and boom welding manipulators, available to buy, rent or lease. Our range consists of Mobile Pipe, Standard, Extra-Heavy and Telescopic models. But if your project demands are non-typical, our in-house capabilities and next-level engineering expertise enable us to develop special purpose machines for those more ‘complexed’ project needs.

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Robust and Rigid Body Kuka HR Series Robot High Accuracy Index Table Custom Design Clamping Fixturing Laser Welding Head Fiber or Disk Laser Laser Safe Class 1 Enclosure Customized HMI

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Manual application of the laser beam obtained from Lamp Pumped (Nd:YAG) 300w and 600w systems without any automation and fixturing. Practical Accessible Light weight Ergonomical Safe Available with; Nd: YAG Laser. Laser operates only when the operator uses the glasses, and the graphite touches the working material Graphite tips are designable specifically for the welding piece and easy to apply Provides economic solutions as fixturing is not required With its ergonomic design, it facilitates welding application in sections difficult to reach Time assist gas control allows for a cleaner surface to be obtained Multiple fiber path, can achieve energy sharing and time sharing Energy negative feedback laser control technology to achieve consistent welding effect Arbitrary waveform control technology to precisely control welding points formed by each pulse energy.

Request for a quote

EWM AG

Germany

The Welding 4.0 quality management system ewm Xnet was specifically developed for the welding production and effectively supports all the employees involved in the welding process (welding coordinator, welder, production manager, manager, etc.). The services provided by ewm Xnet include, on the one hand, the monitoring and the documentation of all welding parameters from any number of networked welding machines. On the other hand, it creates and manages the welding documentation (WPQR, WPS, welding certificates) digitally and opens up numerous evaluation options. Additionally, the Xnet welding management system can take over the management of components including all the information associated with it, such as component identification via bar code, material consumption, welding parameters, etc. Thanks to the modular structure, the Xnet welding management system can be used in small, medium and large companies.

Request for a quote

ORBITEC GMBH

Germany

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters. The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions... Package includes: — Orbital welding system — Display transport protection — Calibration certificate — USB stick Optional: — Water Cooling Unit COOL 50 or EVO COOL — EVO Remote Control — Gas Controller Box

Request for a quote

ORBITEC GMBH

Germany

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters. The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions... Connection to Tetrix 200 or Tetrix 351. Compact and light with the external dimensions (L x W x H) 405 x 325 x 170 mm and weighing only 9.7 kg. Optional: — Water Cooling Unit COOL 50 or EVO COOL — EVO Remote Control — Gas Controller Box

Request for a quote

DOREY

France

For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK? The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers. The material is placed between the pinch rollers and the hot wedge is inserted. Contact is made between the top and bottom of the material and a melting of the coating occurs with a certain speed of the material crossing the hot wedge surface. The pinch rollers then apply pressure to the melted coating to create the lasting bond.

Request for a quote

DOREY

France

For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK? The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers. The material is placed between the pinch rollers and the hot wedge is inserted. Contact is made between the top and bottom of the material and a melting of the coating occurs with a certain speed of the material crossing the hot wedge surface. The pinch rollers then apply pressure to the melted coating to create the lasting bond.

Request for a quote

DOREY

France

For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers. The material is placed between the pinch rollers and the hot wedge is inserted. Contact is made between the top and bottom of the material and a melting of the coating occurs with a certain speed of the material crossing the hot wedge surface. The pinch rollers then apply pressure to the melted coating to create the lasting bond.

Request for a quote

DOREY

France

This special Triad has been designed around the basic finishing needs of the digital graphics market. This package, based on the 1" (25mm) hem wedge and housing, can provide several welding functions including overlap, flat hem, hem cord and pole pocket welds. The Triad Digital Graphics Package is also available with a 1.5" (38mm) wedge for a larger finish size. For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK? The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOREY

France

TYPES OF OPERATIONS TO RUN (SEE VIDEOS ENCLOSED) Double Tube Sewing System Cured in Place Pipeline System Cured in place welding machine Cured In Place Pipeline Manufacturing SINGLE or DOUBLE Layer Welding and Sewing Operations DESCRIPTION This fully automated welding or sewing system manufactures cured in place pipelines or rehabilitation tubes. The machine is capable of welding or sewing two layers of fabric simultaneously one layer of non woven felt on the inside and one layer of coated felt on the outside. The coated felt layer can be coated with PVC, polyurethane, polyethylene or polypropylene. This machine can weld or sew both layers, tack welds layers together all automatically inline simultaneously, saving time improving consistency and increasing quality. FEATURES, FUNCTIONS, & BENEFITS Multiple unwinds for off roll production Continuous operation for increased production Capable of welding or sewing both layers to meet your finishing needs

Request for a quote

ALPHA LASER GMBH

Germany

This stable work table can be used with laser sources from 300 - 900 W, which are integrated in the work table. The modular design allows the use of various optics and focal lengths, so that you can optimally carry out your tasks. The system can be operated either manually - with our instantly responding joystick - and semi-automatically or automatically with the WINLaserNC software. When welding, workpieces are moved precisely on the three axes of movement of the work table. An axis of rotation is also available. The Z axis of the table lifts workpieces up to 450 kg. The laser and motion system are conveniently operated via the control console with an intuitive touchscreen. With the AL-TW you can weld without restricting the work area. This enables the processing of large workpieces. We support you with the implementation of the laser safety measures with our laser safety concept.

Request for a quote

ALPHA LASER GMBH

Germany

The ALFlak systems offer you many options in the field of mobile laser and repair welding. With an extended range and increased travel range, welding positions in deep, complex shapes can be processed easily thanks to the long laser arm - even in deep, bulky shapes. Deposition welding with wire or powder is possible with this laser machine. Likewise, automated welding tasks. The laser device is equipped with a fiber source that guarantees high efficiency and a special beam quality. Both pulsed and CW mode can be used. The integrated performance monitoring ensures reproducible welds. This system is available with laser powers of 300/450/600 and 900 watts.

Request for a quote

ALPHA LASER GMBH

Germany

With the new ALO manual welding laser, you can either work manually or with an axis of rotation for circular welding. The working chamber is easily accessible via leather curtains, but the welding itself still takes place in the shielded laser safety area. The spacious working chamber can be loaded quickly through various openings, without opening doors: a large opening at the front ensures easy access to the welding chamber. The slots on the side enable the operator to position longer components in the machining area and to weld them in a laser-safe manner. Another passage on the bottom of the working chamber allows loading from below. The laser safe leather curtain offers certified laser protection so that the laser device can be placed in any work environment. The armrest is extremely comfortable - ensuring relaxed work. A lot of attention was also paid to good ergonomics. A high-quality extraction system with filter is integrated as standard.

Request for a quote

ALPHA LASER GMBH

Germany

The mobile laser welding machine ALFlak is particularly suitable for laser deposition and contour welding on large machine components, design components as well as on injection moulds and tools The sophisticated movement mechanism of the ALFlak enables you to work comfortably on large components - you can even immerse in deep, bulky shapes with the slim laser arm. With long weld seams, the ALFlak takes advantage of its large travel axes. A weld seam with a length of up to 500 mm is possible without settling - manually or according to a specified program. Welding can be done in manual mode, semi-automatic or fully programmed. The use of an automatic wire feeder or a rotary axis is also possible. It is the versatile possibilities for mobile welding that make it a very special welding system.

Request for a quote

ALPHA LASER GMBH

Germany

This laser system is quickly set up for the welding task. The flexible laser arm can be rotated 360 ° and offers a very high or low working position. The laser head can be rotated to the left and right and the tilt-swivel lens directs the laser beam to the point desired by the operator. The robust housing has stable aluminum handles at the corners for increased impact protection of the edges. Integrated fastening options are available here for easy lashing during transport. The gas bottle can be transported during welding with a small trailer, the 5th wheel on the laser. Generous storage areas and special brackets on the machine sides ensure that tools, welding wire and whatever else is always within reach. Operation is intuitive via a touch display. Some apps help to weld surfaces, shafts and circular welds. The 450 W fiber laser can be used for pulsed welding or for welding in CW mode.

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

SCHADE MASCHINENBAU

Germany

Our steel construction is certified according to the current standards DIN EN 1090-2 and DIN EN 3834-2. We manufacture welded parts, welded constructions and welded assemblies up to execution class 3 (EXC3). Steel construction components such as: - Assembly devices for aircraft or automobile construction - Machine frames for compressor construction - Welded frames such as track systems and transfer tables - High-precision vacuum clamping plates for high-pressure presses - Complete rudder systems We produce both: individual components and small series. Do you have any questions about our techniques, capacities or prices? Contact us, we will be happy to give you direct information.

Request for a quote

FERPLAST SNC

Italy

Ideal for safely storing gas tanks. Welding system certified UNI EN ISO 3834-2. The tank is equipped with: Hinged door with anti-intrusion closure Galvanised roof Tanks inner hooking in chequer plate steel Modular structure Ramp access in sheet metal Safety labelling

Request for a quote

FERPLAST SNC

Italy

Machine suitable for closing bags mm height. 200 mm. 320 and max weight. 5 kg. The welding system belt PTFE allows closing bags made of polyethylene, polypropylene, cellophane, coated paper, laminated aluminum, etc.. The temperature is controlled by an electronic controller and thespeed is adjustable. The distance between the sealing and the edge of the bag is 10 mm. The sealing head is adjustable in height. The machine is equipped with a marker rotary heat and interchangeable characters (20 characters max height 5 mm.), The system works with inked rollers for easy readingand comes complete with photocell to make a mark at the desired point.

Request for a quote

FERPLAST SNC

Italy

Machine suitable for the closing of bags with height, mm. to 150 mm. 270 and max weight. 3 kg. The welding system with belts PTFE allows for closing of bags made of polyethylene, polypropylene, cellophane, coated paper, laminated aluminum, etc. The temperature is adjustable from 0-250° C. and the feed speed is adjustable from 0 -12 mt. / min.The welding head is adjustable in height and the distance between the welding and the edge of the bag is 10 mm. The machine is equipped with rotary solid ink marker and interchangeable characters (up to 20 characters with a height of 5 mm.), The system works with inked rollers for easy management and is complete with a photocell to do the marking in the desired location. This model is constructed in the standard version, that is, the advancement of the product occurs from right to left.

Request for a quote

KULLEN-KOTI GMBH

Germany

Our roller brush coil designed as welded package system will also pack the tiger in your tank! Why is it reasonable and advantageous to purchase a welded package system type 231? Each face width of a roller brush needed can be divided in a corresponding number of single, compact segments, called packages, that are not only loosley coiled spirals. What we produce are light and easy-to-handle packages with a constant high density which facilitates and accelerates the equipping of a brush core or shaft carried out by yourself.The welded package system is not only easy to mount but it also makes you independent of any transportation of the core to the supplier for refilling, packing, delivery times etc. and helps you out of emergency situations.For the core constructions the following materials are available: plastic-coated steel, steel, stainless steel (1.4301; 1.4571; 2.4879). The twin tape mounting is designed as a concave backing system where the coil widths (WB) ranges between...

Request for a quoteResults for

Welding systems - Import exportNumber of results

143 ProductsCountries

Company type

Category

- Welding, soldering and brazing - equipment and supplies (24)

- Laser - cutting and welding machines (21)

- Waste sorting - machines and equipment (10)

- Welding, electric - equipment and supplies (8)

- Autogenous welding machines (7)

- Textiles - Machines & Equipment (6)

- Tanks, metal (5)

- Package sealing machinery (4)

- Welding work - steels and metal (4)

- Electron beam welding - equipment (3)

- Monitoring and control equipment (3)

- Steels and metals - welding and brazing (3)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Silicones (2)

- Welding robots (2)

- Active electronic components (1)

- Bearings - ball, needle and roller (1)

- Cleaning machines, industrial (1)

- Cutting - machine tools (1)

- Cutting - steels and metals (1)