METZEN INDUSTRIES GMBH - When it really matters.

Germany

Manufacturer/ Producer

METZEN INDUSTRIES GMBH

Germany

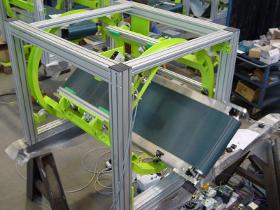

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quote

METZEN INDUSTRIES GMBH

Germany

KROGER Greifertechnik is the internationally leading lifting systems brand. We have been developing and producing superior products for over 50 years. Our grabs stand out thanks to their outstanding handling capacity, long lifespan, low-maintenance bearing technology and their sturdiness. KROGER Greifertechnik is one of the worldwide leading grab systems manufacturers. KRÖGER grabs are successfully used at maritime and inland ports for bulk handling, in warehouses and at industrial or handling sites; as well as in cranes on ships or dredgers for gravel extraction, in excavation diggers, for demolition and waste incineration, in steel mills and in the timber industry. We also repair and refurbish used KROGER and other grabs and offer a reliable spare parts service here at METZEN. We significantly increase your company’s profitability in bulk and bulky goods handling thanks to our senior engineers’, experience, knowledge and motivation, combined with our highly reliable

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Quick port handling – and therefore the reduction of the time that ships spend in port – is a priority for all port operators, regardless of the port’s size and whether it is at sea or inland. This largely depends on the reliability, robustness, and low maintenance requirements of the handling equipment used. KRÖGER’s different grab systems are ideal for the tough 24-hour working reality of ports and for almost all handling requirements. We are also extremely well equipped to design individualised grabs to meet specific requirements. Depending on the handling system, our grabs are equipped with hydraulic, electro-hydraulic or mechanical rope drives. They can therefore be used to unload small inland ships and large seagoing vessels, as well as for bulk cargo handling of any kind.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Energy production from biomass and waste is on the rise throughout Europe and the world. KROGER has been an established, reliable partner in this sector for many years. KROGER’s maintenance-free grab systems are especially advantageous in both safety and economic terms when used in waste incineration plants, refuse-derived fuel (RDF) incineration plants, combined heat and power (CHP) plants and slag handling. In these extremely difficult, hard-to-access environments, maintenance or lubrication work is costly and often risky for service technicians. KRÖGER offers rrope or motor grabs for a variety of different cranes for use in this particular industry.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Gravel extraction: KROGER grabs dredgers and rope extravators allow you to extract gravel and sand from rivers or lakes and have been used for this purpose in the toughest conditions across Europe for over 50 years. Thanks to our maintenance-free underwater motor and ropemechanical grab systems, you can extract gravel and sand in new locations whilst complying with environmental regulations and increasing your profitability. Our grabs are particularly suitable for use on difficult terrain and at extreme depths. Our latest record also bears witness to this: our experience paid off when KROGER grab became the European champion with a dredging depth of 177 meters during excavation in Lake Lucerne. Reliability matters – even when extracting gravel and sand at new depths.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Our KROGER rope grabs are used on cranes for gravel extraction, port handling and waste processing to lift high and even maximum loads. They are individually designed for 2-point or 4-point suspensions. Their clamping force equally varies, with 3 to 7-fold reeving. All KROGER grabshave low-maintenance or maintenance-free design, which benefits both the environment and your profitability.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of crane with internal or external holding ropes. Technical design Low-maintenance or maintenance-free design, which benefits both the environment and your profitability Transverse or longitudinal suspension with 3-fold, 4-fold and 5-fold rope reeving; as 2-rope and 4-rope grabs High load capacity thanks to its lightweight design Smooth grab thanks to its low centre of gravity and because the rope’s diameter matches that of the pulley Retracted pivots for easy grab under the ship’s gangway Large plastered surface to grip the residual charge Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Lower pulley block unrestrained on the crossbeam Rope pulley bearing: Plain bearing KROGER MAINTENANCE-FREE pulley block system Grab shells: Material: S355J2+N

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For bulk handling of any kind up to 2,000 kg/m3 in inland ports, especially suitable for unloading narrow shipping spaces. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of crane with internal or external holding ropes, exclusively for transverse suspension. Technical design Low-maintenance or maintenance-free design, which benefits both the environment and your profitability Transverse or longitudinal suspension with 3-fold, 4-fold and 5-fold rope reeving; as 2-rope and 4-rope grabs High load capacity thanks to its lightweight design Smooth grab thanks to its low centre of gravity and because the rope’s diameter matches that of the pulley Retracted pivots for easy grab under the ship’s gangway Large plastered surface to grip the residual charge Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Lower pulley block unrestrained on the crossbeam Rope pulley bearing: Plain bearing

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling general scrap, car bodies, steel chips, shredder scrap, paving stones and much more, in sea and inland ports. For pier engineering and riverbed maintenance. For various types of cranes and excavators with internal or external holding ropes. Technical design As 2-rope and 4-rope grabs with open, half-closed or closed grip Suitable for handling scrap, stones, waste and other difficult to grab goods depending on design Closing rope devices: Rope nozzles KRÖGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Rigidly mounted main casing to accommodate the lower rope pulleys, easily move the ropes and reduce wear on them even when the crosshead is at an angle whilst the grab is being operated Rope pulley bearing: Re-greaseable plain bearing KRÖGER MAINTENANCE-FREE pulley block system Grab connection bearing: Re-greaseable steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system Stable shell structure with shells made out of S355J2+N.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Slag handling in waste incineration plants or incineration plants of any kind. For various types of cranes with internal or external holding ropes. Technical design Low-maintenance or maintenance-free for increased profitability Transverse or longitudinal suspension with 4-fold, 5-fold and 7-fold rope reeving; as a 4-rope grab High load capacity thanks to its lightweight design Smooth grab thanks to its low centre of gravity and because the rope’s diameter matches that of the pulley Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Lower pulley block unrestrained on the crossbeam Rope pulley bearing: Re-greaseable plain bearing KROGER MAINTENANCE-FREE pulley block system Grab shells: Material: S355J2+N Cutting edge material: special, highly wear-resistant steel Grab connection bearing: Re-greaseable steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system

Request for a quoteManufacturer/ Producer

Brandstwiete 4

20457 Hamburg - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

TRAPO GMBH

Germany

4- or 6-axis jointed-arm robots of various well-known brands are acting highly flexible. The high-speed systems palletize, sort, load and commission fast and high-precision single pieces, rows, partial layers or complete layers. - Low space requirement - Flexible use for various applications - Product and industry independent: Mature gripper technologies transport a wide variety of goods - Suitable for different packages and load carriers - Set on rails, the jointed-arm robot moves to different palletizing positions - Application-oriented, flexible combination of the optimally complementary technical properties of high-speed palletisers and robots

Request for a quote

TRAPO GMBH

Germany

Our high-capacity portal palletizers act in a material-caring manner on three servo-linear axes within cubic space. We develop, design and manufacture portal robots in our in-house production facility in Gescher-Hochmoor. We are a specialist in the high-care segment -with portal robots made of high-grade steel.

Request for a quote

TRAPO GMBH

Germany

As a supplier of complete systems, TRAPO AG supplies modular High-Performance-Pick & Place-Systems that combine components such as robots, frame units, camera systems and conveyor technology. The modular system can be adapted to different framework conditions and thus covers almost any application. The TRAPO HPPS series forms the heart of the modular picker cell. The high-performance picker line combines maximum performance, individual TRAPO gripper technology and proven know-how, for example in the field of hygiene design.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Chain conveyors made to handle severe-duty, highly abrasive, metal chips, fines and swarf. Transfer and elevate the most difficult and abrasive wet or dry metal chips, fines, swarf, die scrap and other materials with this rugged, chain driven, liquid-tight conveyor. Every part of this rugged chain driven conveyor is designed for severe duty. The Heavy-duty, abrasion-resistant flight bars of the scrap conveyor feature an exclusive bolt-free connection so they stay strong under grueling conditions. The abrasion-resistant steel press-formed trough is liquid tight and comes standard with safety covers

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free