SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Manufacturer/ Producer

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Safe storage and transport: Siempelkamp is your container manufacturer for heat-generating and non-heat-generating radioactive materials Wide range of designs for all classes We produce a variety of containers for handling radioactive materials of all classifications. The choice of materials ranges from the use of different casting qualities to granulated concrete and steel. The range of services is completed by the authorization to carry out type tests. For more than 30 prototype types, the required certificates of qualification for the transport and storage of the casks have already been successfully completed in our manufacturing facilities. CASTOR ® casks bodies CASTOR ® casks are used as transport and interim storage containers for fuel elements and high-level radioactive waste.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

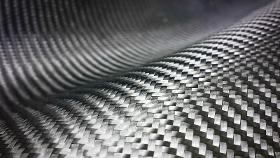

Fiber-reinforced composites are in demand in all high-end industries in which light weight and at the same time high durability under dynamic load ensure competitive advantages Efficient and reliable press technology for fibre composite plants Whether glass fibre reinforced plastic (GRP) or carbon fibre reinforced plastic (CFRP): The valuable material is mainly used in application fields where weight reduction, fuel consumption,anti-corrosion characteristics and other stress resistency feauters are in focus. The name Siempelkamp also stands for solid and precise technologies in these presses and handling systems as well as for high flexibility due to its suitability for all composite applications such as sheet molding compounds with glass or carbon fibers (SMC), prepreg compression molding with short, long or continuous fibers (PCM), resin transfer molding (RTM), and thermoplastic forming.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The SMC presses from Siempelkamp are designed in such a way that they can also be used for the RTM process. Short cycle times Since the SMC process is predominantly used in the production of high quantities, apart from precision, a short cycle time plays a important role. And since the compound material is chemically reactive, the time window for achieving an optimum surface quality is also small. The advantages of the Siempelkamp presses: they apply the force extremely quickly to the product, because they close at a very high speed decelerating just before reaching the end position. Depending on the level of automation, the tool change is done automatically – just 120 seconds later the next part can be produced! No stress The precise positioning of the ram plate ensures that the tools are precisely aligned to each other during the complete press stroke – not just on the last millimeters. Under all operating conditions the tools remain parallel.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

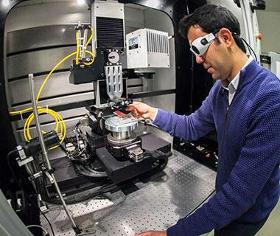

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Pioneering partnerships: Networking in our industry Siempelkamp actively contributes to the development of the industrial use of composite components with funding projects, cooperations with universities and industry partners as well as memberships in associations. Current R&D topics are for example: the manufacture of large-area structural components for the aerospace industry the integral construction approach, which combines several functions in one componen the further development of thermoplast forming for the industrial process the production of hybrid components made of ber reinforced plastic and metal for the automotive industry Through our active cooperation in associations, we are shaping the future of composite production. As a part of the competence network CFK Valley e.V., we contribute with our experience to the construction of presses for the practical application of ber composite and other lightweight construction technologies in the aircraft and automotive industry.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Sustainability is very important to us, so we buy back existing plants, upgrade and adapt them to customer needs Siempelkamp machines and plants go through a sustainable life cycle We buy back machines and entire plants that were in operation and adapt them to the individual needs of our customers. We modernize used plants and upgrade them to current industry-standards with increased performance. Siempelkamp offers you a wide range of pre-owned machines and plants When purchasing a plant that has been in operation, professional and cost-effective implementation of all measures - from dismantling to commissioning - are decisive processes for project success. We offer you second-hand plants for the production of particleboard, MDF and OSB with continuous press systems from well-known brands such as Siempelkamp, Küster, Bison, and Metso.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

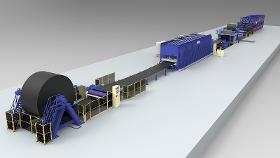

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

For the production of conveyor belts with steel-cord or fabric layers, Siempelkamp oers a multi-cylinder down-stroke press including 2-track production. Conveyor belts having a width of up to 3,200 mm and a thickness of up to 50 mm can be manufactured at a pressure of 400 N/m2. To this end, Siempelkamp's multi-cylinder presses provide a pressure distribution previously unattainable with hydraulic-mechanical press systems. In addition, the thickness tolerances of the conveyor belts could be reduced here compared to traditional press concepts. Services Conveyor belt thickness starting at 5 mm Optimal pressure distribution due to our multi-cylinder concept Material reduction by eliminating the hot platen insulation Stable press gap parallelism High safety standards Advantages Improved process safety Low material and production costs due to reduced thickness tolerances Minimal foundation requirements Ease of maintenance and long service life

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp’s steel-cord conveyor belt presses distinguish by an innovative steel-cord tensioning concept: the controlled steel-cord tension distribution system increases production safety and improves product quality. The electromotive tensioning system, which is individually controlled and installed directly in the creel with integrated measuring and control functions, allows a 100%-control over the actual steel-cord tension distribution. The exact quality reporting enables our customers to optimize the production, hence the product’s quality. The new concept replaces the xed-nger comb used in previous systems with a roller comb. The friction between comb and steel cables is thus eliminated. Consequently, the abrasive wear on the galvanized steel cables is reduced. Unlike the traditional concept, the new roller comb prevents any variations in tension distribution. Services Direct tensioning control in the creel Individually controlled steel-cord tension distribution

Request for a quoteManufacturer/ Producer

Siempelkampstr. 75

47803 Krefeld - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in mechanical shaft.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Silencers/Mufflers; diesel and gas engine exhaust noise is designed based on required target noise levels and current pressure drop. In addition to the standard silencers for stationary engines, special silencers are designed and manufactured according to customer specifications. In addition to reducing exhaust noise, extremely compact designs are made with the available space in mind.

Request for a quote

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free