STRECKFUSS SYSTEMS GMBH & CO. KG - Innovative Lötanlagen

Germany

Manufacturer/ Producer

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TITANIUM The new generation of wave soldering systems – lead free soldering without corrosion. TITANIUM is the innovative soldering solution developed by STRECKFUSS SYSTEMS. It uses titanium, an agent which is extremely lead free solder resistant. For this reason, titanium works perfectly in lead free soldering processes. An oxide film immediately covers all material damages and thus prevents corrosion. In contrast to wave soldering systems with stainless steel components, titanium is not subject to corrosion even when lead free solder is used. By means of a simple and safe solder bath exchange, TITANIUM makes it possible to switch flexibly from a standard soldering process to lead free production. This ensures maximum flexibility at minimum costs and easy handling. TITANIUM is a complete system and includes: Spray fluxer with extraction hood Double wave 3- D wave (for the prevention of solder bridges) Infrared preheating Microprocessor controls Soldering frame transportation system

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

SELECTIO Selective soldering systems for automatic single point soldering and multiple point soldering It is not always possible to use mass soldering processes such as wave soldering to perform a certain soldering task. Individual soldering steps are often necessary. To automate this process and to lower the costs while maintaining the high quality requirements, STRECKFUSS SYSTEMS has developed the selective soldering system SELECTIO. Just like our wave soldering system TITANIUM, SELECTIO too is equipped with the corrosion and tin resistant agent titanium and therefore works perfectly for lead free soldering. Product characteristics – an overview: x/y/z- axes system with precision toothed drive belt transport system and assembly carrier standard stand- alone- system (offline system): optional transportation belt connection as inline system printed circuit board transportation with assembly carrier soldering processes: single point nozzle and surface nozzle as well as dip soldering via mask technique fluxing out of vendor's flux container with multi- drop- fluxer nozzle short wave IR- quartz- radiators for preheating of printed circuit boards pyrometer for contact- free temperature check of printed circuit boards easily exchangeable soldering nozzles Microsoft© Windows user surface and process visualization: - BDE for documentation complying with DIN ISO 9000 ff - management data organization - optional real- time video surveillance

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

Component lead preparation Our customer service includes component lead forming. The product describtions are available in German only. We offer systems for the following process steps: Rivet press Solder tag insertion Lead trimming Lead forming of axial components Lead forming of radial components DIL Package Cut and Form Wire jumpers The submenu above will take you directly to the product. Feel free to print them out. We have optimized to the following pages for printing.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

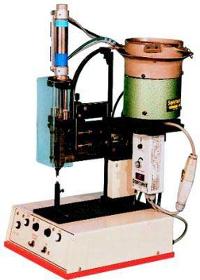

TYP D 020 Automotive Press for pressing of rivet nuts, connectors, etc. Usage To reline of these connectors Automotive Press was formerly developed. Meanwhile, this device will multiply its application when it comes to press- fit components into the PCB (eg connectors). Also for joining several PCBs or PCB components, the press can be used. Operation Through the use of different tool inserts, which can be easily replaced in the nut tool, different assembly operations can be greatly facilitated, that have often been carried out laboriously on a toggle press. Due to the size of the motor press D 020 can be permanently mounted in the workplace or on a mounting bereitgestelllt car. The operation is simple: the circuit board is inserted with the part to be pressed in the operating range of the device against the stop. Then a limit switch triggers the workflow. By a nearly closed guard is no danger to the operator.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

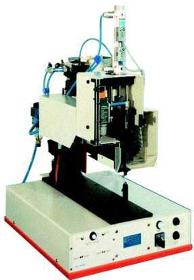

TYP A 040 Solder lug insertion device Description The solder lug insertion device Type A 040 is designed to insert pre- stored solder lugs into p. c. boards. The components are supplied automatically to the device, and will be pressed into the p. c. board by an air cylinder. Therefore, the p. c. board has to be held to the setting position manually, and a tracer finger then triggers the setting process. The inserting device will handle all usual in the trade solder lugs, which are lined up on wire or adhesive tape. Replacing the insertion head and the bin makes it possible, to process solder tags with different dimensions and forms. The re- tooling is easy, and takes only a few minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 040/B Solder lug inserting with tape feeder Description The solder lug inserting device Type A 040 B, was constructed for a mechanised insertion of solder lugs. Fixed cycles of less than one second are within easy reach. A Foot pedal controls the individual stroke sequence. The taped solder lugs are automatically fed into the machine. Therefore, no additional material and wage costs for threading the solder lugs on leads will arise. The device is able to process all kind of taped solder lugs with standard forms. After a slight alternation, solder lug strips, which deviate from standard, can also be processed. To do this, you simply have to replace the insertion head with stripe guide and the cutting tool, which is fast and easy to do. All driving elements and electrical switches belong to the main machine and therefore, they do not have to be moved. The bearing pedestal for the material bin can hold coils up to 500 mm ø. An adjustable conical ring centres the coil on the bearing pedestal. Working with this device is very easy and save. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 040/R Solder lug inserter Description The Streckfuss solder lug inserting device Type A 04 R is designed, to insert solder lugs into p. c. boards. The Solder lugs are automatically moved into the device by a vibrating conveyor. An air cylinder then presses them into the p. c. board. To do this, the p. c. board is to be held manually to the setting position. The setting process by itselve is triggered over an tracer finger. This inserting device is able to process all kind of usual in the trade solder lugs (incl. double tongues), which can be supplied by a conveyor for bulk materilas. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 041 Solder lug inserter Description The device Type A 041 is designed, to insert stored solder lugs (solder posts) into p. c. boards, spool bodys or contact banks. The solder lugs are pressed into the p. c. boards by an Foot pedal- activated air cylinder. The p. c. board is centered by a insertion pin. The device can optionally be equipped with a light point adjustement. All usual in the trade solder lugs which are lined up on wire or adhesive tape can be processed. Retooling to different solder lug forms is possible and easy to do. The p. c. board is placed in the frame and will be adjusted. After that the p. c. board has to be shifted manually into the working area. The setting postion can be placed trough a luminous spot. The insertion itself is triggered by a Foot pedal. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 042 Round pin inserter Description The Streckfuss inserting device Type A 042 offers the economical solution, for the mechanised insertion of round pins, solder posts and or - lugs into p. c. boards. With this device, nearly all customer forms of round pins, solder posts / - lugs can be processed. The loose components are filled into the sorting pot of the vibration conveyor. Trough barriers in the helical of the conveyor, the components are ordered. After positioning, the components are handed to the loading slider, which supplies the components to the inserting tool. Working with this device is save and easy: For assembling, hold the p. c. board with both hands on the edges, and place it under the inserting tool. The p. c. board now lies at the bottom of the pressure stamp, while the tooling pin hole is placed directly under the solder post / - lug shaft looming out of the inserting tool. This has the function of a locating pin. The p. c. board is lifted parallel, so the components shaft enters the tooling pin hole. The insertion process is triggered by a foot switch. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 053 Universal cutter for radial components Description The Streckfuss Device Type C 053 is designed to cut the leads of axial or radial leaded components incl. IC's to required length. Cover plate and cutting tip are drilled with each other, so all leads will be cutted simultaneously. The plates are made of high- quality tool steel hardened to 60 HRC and polished. Components

Request for a quoteManufacturer/ Producer

Kruppstraße 10

76344 Eggenstein-Leopoldshafen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

MTA ROBOTICS AG

Switzerland

The mta OEM soldering robot for integrator can be used for semi or fully automatic operations of selective point to point soldering from above. Thanks to its unique concept, the OEM robot is delivered to the system’s manufacturer with a process guarantee. The OEM robot can be equipped with any of mta’s soldering heads: soldering iron, induction, microflame; except for the mta MLH45 laser head. The 3 or 4 axes of the OEM robot are fully programmable through the mta-MotionEditor software, including soldering parameters such as: Solder quantity, wire feed speed, preheating/postheating times, automatic tip cleaning cycle intervals and other parameters for each soldered point. With its flexible and modular concept, the OEM robot can be fully and easily integrated into a production line.

Request for a quote

ANTHERMO GMBH

Germany

Numerous designs available at short notice Support-free assembly Nipple outlets (MSS SP 97) have been specially developed for support-free assembly. Nipple outlets are available with different ends. Smooth or beveled ends are used for welded connections, while the ends have an external thread for screw connections. We can deliver nipple outlets with NPT thread according to ASME B1.20.1 from our warehouse. We can deliver nipple outlets with BSP / T threads according to ISO 7-1 and BSP / P threads according to DIN ISO 228 with short delivery times. Standards and special requests We deliver nipple outlets in different wall thicknesses (STD, XS, S 160 & XXS and special wall thicknesses) as well as in all common materials. If required, we can also supply special materials. Technical specifications You can find more details, technical data and dimensions in our data sheet "Nipple outlet" in the download area.

Request for a quote

MTA ROBOTICS AG

Switzerland

The TR300 is mta’s table-top soldering robot platform. This robot is purpose-built and standardized for semi-automated applications that require point-to-point soldering. The table-top platform is a cost-effective solution to automate existing hand-soldering processes without the cost of fully-automated systems. Automating the solder process has several advantages over hand soldering. It produces highly consist joints, improved quality, higher throughput, and it requires less skill and training than hand soldering. This table-top soldering robot platform is also ideal for applications where human dexterity is required to position the parts. This is because operators can load and unload the parts in offline fixtures to minimize machine downtime. Because the TR300 is a purpose-built solution, it can support any of mta’s soldering heads without compromise. The ball-screw axis and motors provide fast repeatable motion.

Request for a quote

MTA ROBOTICS AG

Switzerland

As a complement or an alternative to wave, mini-wave and traditional selective soldering techniques, the MPS700 bottom side selective soldering machine provides maximum accessibility and meets mass production requirements of quality, reliability and cycle times. The iron head is equipped with a powerful heating element and a high precision wire feeder. The solder point positions are adjusted using a compact vision system close to the iron head. A 4-axis system guarantees quick and precise movements. The MPS700 can be equipped with mta classic soldering iron head and MSH150 soldering iron head.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free