STRECKFUSS SYSTEMS GMBH & CO. KG - Innovative Lötanlagen

Germany

Manufacturer/ Producer

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

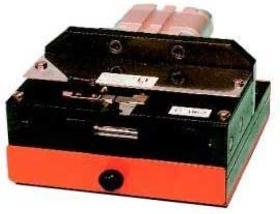

TYP C 043 Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043 is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/B Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - if necessary - marked. This axial taped components are processed in high- components. The machine type C 043 / B can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/BS Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - are marked - if necessary. This axial taped components are processed in high- components. The machine type C 043/BS can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/E Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043/E is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/ES Cutting, stamping and bending device for axial components Description To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Cutting length and pitch are fully adjustable. The stamping result for the leads depends on the used tool. Leadforming ist tool specific and can be manufactured to meet customer requirements. The difference to the types C 043 and C 043 E is the integrated Pneumatic which makes the rearrangement of the Bending- and Formingtools possible. This means, that the tools can be approached to the components. Espacially bendings with Flush- Mount- bead can be done. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 044 Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 044 is designed, to cut and form the leads of axial components for vertical mounting. A variety of form shapes are avalaible through the use of interchangeable die sets. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length and formed to required raster. The set up adjustments are quite simple and secured to provide accurate forming of every compöonent lead. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 044/S Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - if necessary - marked . This axial taped components are processed in high- components. In the device 044 C / S to be bent, the components are manually inserted into the device and processed by triggering the pneumatic foot switch. The high- axial component can be provided either at one or at both terminal wires with a bead for preventing falling out of the printed circuit board according to the manual setting operation. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 055/S Universal Cutting and Forming Device for radial components Description The Device Type C 055 S was developed espacially for the moderate cutting and forming of components with axial or radial leads (incl. ICs). Cutting and forming the leads will be done in one working cycle. Changing the die sets takes no longer than 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 062 Cutting, stamping and bending device for radial components Description The Streckfuss device Type C 062 is designed to process loose components with radial leads. Cutting and bending of the leads is done in one step including integrated strength member to eliminate axial strength uppon the component case. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 063 Cutting, stamping and bending device for radial components Description The device processes power transistors and diodes to the types of housing TO 92, TO 18, TO 126, TO 127 and TO 220 with a maximum of three radially running connections. However, other components can be processed (for example, LED). The cutting and bending of the connecting wires is carried out in one step and of course including cable strain relief in order to avoid axial forces on the component housing. When a component which is to be bent, embossed and cut, two processing stations are necessary. Components

Request for a quoteManufacturer/ Producer

Kruppstraße 10

76344 Eggenstein-Leopoldshafen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

MTA ROBOTICS AG

Switzerland

The mta OEM soldering robot for integrator can be used for semi or fully automatic operations of selective point to point soldering from above. Thanks to its unique concept, the OEM robot is delivered to the system’s manufacturer with a process guarantee. The OEM robot can be equipped with any of mta’s soldering heads: soldering iron, induction, microflame; except for the mta MLH45 laser head. The 3 or 4 axes of the OEM robot are fully programmable through the mta-MotionEditor software, including soldering parameters such as: Solder quantity, wire feed speed, preheating/postheating times, automatic tip cleaning cycle intervals and other parameters for each soldered point. With its flexible and modular concept, the OEM robot can be fully and easily integrated into a production line.

Request for a quote

MTA ROBOTICS AG

Switzerland

The TR300 is mta’s table-top soldering robot platform. This robot is purpose-built and standardized for semi-automated applications that require point-to-point soldering. The table-top platform is a cost-effective solution to automate existing hand-soldering processes without the cost of fully-automated systems. Automating the solder process has several advantages over hand soldering. It produces highly consist joints, improved quality, higher throughput, and it requires less skill and training than hand soldering. This table-top soldering robot platform is also ideal for applications where human dexterity is required to position the parts. This is because operators can load and unload the parts in offline fixtures to minimize machine downtime. Because the TR300 is a purpose-built solution, it can support any of mta’s soldering heads without compromise. The ball-screw axis and motors provide fast repeatable motion.

Request for a quote

MTA ROBOTICS AG

Switzerland

As a complement or an alternative to wave, mini-wave and traditional selective soldering techniques, the MPS700 bottom side selective soldering machine provides maximum accessibility and meets mass production requirements of quality, reliability and cycle times. The iron head is equipped with a powerful heating element and a high precision wire feeder. The solder point positions are adjusted using a compact vision system close to the iron head. A 4-axis system guarantees quick and precise movements. The MPS700 can be equipped with mta classic soldering iron head and MSH150 soldering iron head.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free