- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cam mechanisms

Results for

Cam mechanisms - Import export

-

COLOMBO FILIPPETTI S.P.A.

Italy

-

STRIP'S D.O.O.

Slovenia

-

DUNDAR ELEVATOR - KERNEK ASANSÖR (UCGEN MUHENDISLIK)

Turkey

-

YVES ALLAIN AEROSPACE CONSULTING YAAC

France

-

JMP CO.

United States

-

SONZOGNI CAMME SPA

Italy

-

CAD-CAM ENGINEERING SOLUTION SRL

Romania

-

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

-

HENKEL MODELLBAU GMBH

Germany

-

GRAVOTECH

France

Product recommendations

Netherlands

France

China

Poland

-

VOGT GMBH CERAMIC COMPONENTS

Germany

-

WETEC GMBH

Germany

-

NOVAL METAL ALUMINIUM GMBH

Germany

-

OFFICINE MECCANICHE ORNAGO

Italy

-

GRUP MOFRÁN

Spain

-

DERYA M.D.M SAN. VE TIC. A.S / GLASSYMOULD®

Turkey

-

EROC

France

-

TECHNIC GROUP ENGINEERING

Turkey

-

AM PURCHASING

Greece

-

HFM MODELL- UND FORMENBAU GMBH

Germany

-

IT-MECHANICA-KG

Serbia

-

HME AG MASCHINENBAU

Switzerland

-

SDC

France

-

ASSET INSTRUMENTS ENGINEERING LTD

United Kingdom

-

FABAL ALUMINIUM

Turkey

-

SAM ENGINEERING

Italy

-

BAFASAN MAKINE SANAYI IÇ VE DIS TICARET ANONIM SIRKETI

Turkey

-

KMP

France

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free

Find quotes for

Results for

Cam mechanisms - Import exportNumber of results

51 CompaniesCountries

Company type

Category

- Milling - steels and metals (7)

- CAD/CAM Computer Assisted Design/Computer Assisted Manufacturing - software (6)

- Precision mechanics (6)

- Steels and metals - machining (5)

- Mechanical engineering - custom work (4)

- Engineering - industrial contractors (3)

- Machine tools - metal machining (3)

- Plastics moulding (3)

- Screw cutting - steels and metals (3)

- Engineering - industrial consultants (2)

- Injection moulding of rubber and plastic (2)

- Moulds, plastic and rubber industry (2)

- Aluminium alloys (1)

- Articulated vehicles and semitrailers (1)

- Automation - systems and equipment (1)

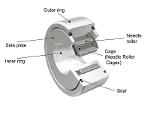

- Bearings, needle (1)

- Central purchasing office (1)

- Ceramic, components - electric (1)

- Ceramics, industrial (1)

- Cutting - machine tools (1)