- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining steels

Results for

Machining steels - Germany

Product recommendations

China

Germany

Turkey

China

-

VOM HOFE KALTSTAUCHDRAHT GMBH

Germany

-

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

-

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

-

IMM MASCHINENBAU GMBH

Germany

-

MOSCA GMBH

Germany

-

SCHWARZ SYSTEMS GMBH

Germany

-

SCHADE MASCHINENBAU

Germany

-

MSG MASCHINENSERVICE GERA GMBH

Germany

-

WALTER SCHNEIDER GMBH

Germany

-

SCS-METALL GMBH

Germany

Product recommendations

Germany

Italy

China

China

-

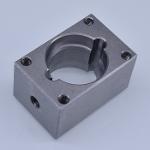

IAV DREHTEILE GMBH

Germany

-

MANTIS ULV SPRÜHGERÄTE GMBH

Germany

-

BOLZ PROCESS TECHNOLOGY GMBH

Germany

-

PETER EISENREICH GMBH

Germany

-

GEORG NIEDER E.K.

Germany

-

DEUTENBERG DRAHTTECHNIK GMBH

Germany

-

STEEL SERVICE KREFELD GMBH

Germany

-

WALTER GMBH

Germany

-

ASPROVA AG

Germany

-

B&H BESCHLAGTECHNIK OHG

Germany

-

KYFFHÄUSER MASCHINENFABRIK ARTERN GMBH

Germany

-

LAVAIR AG KLIMATECHNIK

Germany

-

GASTRO MERCADO S.L.

Germany

-

AK REGELTECHNIK GMBH

Germany

-

MBE COLOGNE ENGINEERING GMBH

Germany

-

R&P FERTIGUNGSTECHNIK GMBH

Germany

-

CHEMEGRA CHEMISCHE UND MECHANISCHE GRANULATVERARBEITUNG GMBH & CO. KG

Germany

-

HAGENKÖTTER GMBH & CO.

Germany

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free

Results for

Machining steels - GermanyNumber of results

18,150 CompaniesCountries

- Germany (18150)

- Berlin and region (354)

- Bonn, Düsseldorf and North Rhine and Westphalia (4279)

- Bremen and region (113)

- Frankfurt am Main and Hesse (1089)

- Hamburg and region (208)

- Hannover and Lower Saxony (1330)

- Kiel and Schleswig-Holstein (472)

- Leipzig and Saxony (1074)

- Magdeburg and Saxony-Anhalt (446)

- Mainz and Rheinland-Pfalz (870)

- Munich, Nuremberg and Bavaria (2712)

- Potsdam and Brandenburg (484)

- Saarbrücken and Saarland (200)

- Schwerin and Mecklenburg-Vorpommern (259)

- Stuttgart, Freiburg and Baden-Wurtemberg (3546)

- Weimar and Thuringia (714)

Company type

Category

- Steels and metals - machining (18076)

- Steels and metals - surface treatment and coating (14691)

- Industrial building construction (9745)

- Metal construction, lightweight (8687)

- Hand tools, non-power (4964)

- Portable power tools (3285)

- Machine tools - metal shaping (3125)

- Grids, gratings and wire mesh (1998)

- Steels and metals - forming and cutting (1723)

- Machine tools - metal machining (1680)

- Turning - steels and metals (1595)

- Locks, bolts and keys (1399)

- Cutting - machine tools (857)

- Ores, ferrous and non-ferrous (785)

- Heat treatment of steels and metals (659)

- Steel (539)

- Nuts and bolts (458)

- Windows (436)

- Machine tools, metal machining - parts and accessories (343)

- Metals, precious and special (307)