- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- monitoring and control equipment

Results for

Monitoring and control equipment - Import export

SDT ULTRASOUND SOLUTIONS

Belgium

A turn-key condition monitoring solution combining the versatility of ultrasound, the analytics of vibration, standard communication protocols and an embedded trending and analysis software. Vigilant Configure Vigilant to any Critical Asset Vigilant is a flexible data collection pod. Input any combo of eight ultrasound and vibration sensors and receive continuous feedback from your assets. 4 channels for Temperature, Tach and Pressure create an all-in-one solution for critical and guarded assets. Vigilant Highlights: - 8 channels (Ultrasound or Vibration) - 4 channels (Temp/Tach/Process) - Embedded data management software - Trends/Spectrum/Waveform/Waterfall - Open communications protocol - Static and Dynamic data

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

CONMONSense delivers precise, repeatable data about the health of your assets and electrical systems also in the most challenging environment. Its resonant piezo element is optimized for ultrasound driven lubrication, mechanical fault detection, and monitoring the health of valves, steam, hydraulic systems and electrical defects. Ultrasound is a true measure of the FITness of your facility. Most assets produce FRICTION, IMPACTING, and TURBULENCE as defect indicators. CONMONSense hears these phenomena at their inception and delivers an analog signal response to your connected measurement system. With an output range from 4-20mA or from 0-10V, CONMONSense mounts permanently to any asset to provide continuous condition monitoring data. Avoid unplanned downtime and put the safety of your plant and colleagues first.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Peace of mind and reassurance for the operator Tightness Testing on Underground Storage Tanks and other Air Tight Compartments The ability to test for tightness with an ultrasound detector is extremely powerful and versatile. It is the only way to ensure that underground storage tanks are air tight. But that isn’t all that ultrasonic tightness testing can be used on. There are many things that need to be air tight. Like the engine or cabin of a car, large shipping containers or the bearing housing in a paper production plant. When somethings tightness integrity deteriorates one or two things can happen. Things can leak out, or things can get in. And whenever possible, it is advantageous to avoid either of these from happening. Fuel Leaking From Underground Storage Tanks Damage the Environment and Waste Valuable Resources Overtime the tightness integrity of underground storage tanks or other air tight compartments can deteriorate.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Valves play a crucial role in the transportation of gas, oil and water throughout your plant. They start and stop flow while also preventing backflow and regulating flow and pressure. They can be found in the hundreds and even thousands at large facilities. Steel, pulp, food and pharmaceutical as well as other industrial facilities installed on their pipes. When valves fail or leak it will result in the loss of energy, product quality and can also lead to potential downtime. Whether it’s internal or external leaks, or issues with flow regulation, valve leaks are a threat to your factory processes. A major component to a plants efficiency is valves operating properly. Ultrasonic inspection can quickly identify function and malfunctioning valves. So they can be tagged and repaired quickly to avoid, diminished production.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

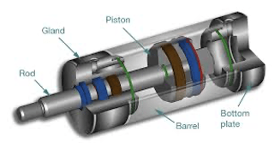

Non-rotating asset components seldom receive the routine surveillance they need Hydraulic systems represent another way industry converts electricity to mechanical energy. A pump, normally powered by an electric motor, moves hydraulic fluid through a system. The system is typically made up of a reservoir to hold the hydraulic fluid, high pressure lines to carry the fluid, control valves that ensure the fluid is sent where needed, relief valves for safety, and cylinders to produce mechanical energy. The pump and motor receive attention while the balance of the system is run-to-failure. Ultrasound testing could change this lackadaisical approach; especially considering its versatility, ease of use, and applicability to most hydraulic defects. External and Internal Leaks External leaks can often be found by visual inspection. Some external leaks, like a ruptured hose or fitting, are easy to spot. Simply follow the trail of spilled oil. Others are not so obvious.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SDT ULTRASOUND SOLUTIONS

Belgium

Safely Inspect Electrical Systems with Ultrasound Electrical failures pose a tremendous safety threat and have the ability to shut down operations entirely Industrial plants require a lot of power to operate, and much like the machinery required for production, their electrical systems can also fail. The Importance of Maintaining your Electrical Systems The implications of a total electrical system failure are far more severe than that of an ordinary mechanical failure. They have the potential to damage equipment, cut power flow and cause downtime for days, seriously injure or kill workers in the immediate vicinity and even impact the surrounding areas power grid. Faults in electrical systems can be detected at their earliest stages with regular ultrasound inspection and therefor prevented far before anything catastrophic happens.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Find Air Leaks. Decrease Energy Consumption. Maximize Uptime. Compressed air is the most versatile and therefore widely used resource in industry. Using atmospheric pressure to transfer energy during industrial processes, compressed air can be found powering air tools like drills and hammers, hydraulic air cylinders for automation in manufacturing processes and much more. Compressed air is also used to power air brakes on mobile fleets and trains. Air Compressor Expenses It is so commonly found in industry it is often referred to as the fourth utility to electricity, water and gas. Of the four, compressed air consumes the most energy. Air compressor systems can differ very greatly in size, output and cost. What remains constant, is the initial investment in a compressor system is only 25% of the expenses associated with it, over its lifetime. The other 75% of the costs go to energy used to compress the air.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Why we Lubricate Bearings For 4000 years we have been lubricating our machinery and rotating assets to increase their efficiency, reliability and lifespan. Proper bearing lubrication minimizes the surface contact of machinery, reducing undesired friction, excessive heat, metal-on-metal contact and wear and tear. Lubrication not only protects ball and roller-element bearings from themselves by reducing friction but also from corrosion and the elements. Grease is the lubrication of choice within the industry, as it is easy to apply and it provides the bearing housing with a protective seal from the elements. For a procedure proven reliable for the past 4 millennia, it is surprising to hear so many premature bearing failures are lubrication-related. Improper lube selection, amount, intervals as well as lubricant contamination and degradation are to blame.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Online4US is a multi-channel online monitoring solution that combines both ultrasound and vibration sensors in 4 to 32 channel modular configurations. It answers a necessary demand to have advanced warning of critical asset failure in remote areas. Online4US is designed to provide Reliability teams with continuous feedback about the health of their factory’s most critical assets. It combines data from two of the most relevant asset condition monitoring disciplines (Ut/Vib) to provide advanced insight about potential machine failures. SDT envisioned a need to permanently monitor the condition of critical assets in inaccessible, dangerous, or remote areas. The versatility of Online4US lends its deployment for identifying early stage machine faults before they become catastrophic events. Online4US is designed to remotely identify these defects Bearing condition monitoring Low speed rotating machine defects On-condition acoustic lubrication

Request for a quote

GEMONE

Belgium

Save both time and money by staying informed about the whereabouts of your machines not only during daily operations but also in case of incidents. GemOne provides real-time tracking of your fleet and securely stores the data, enabling you to utilize it for reporting or making business decisions. Rest assured, it fully complies with GDPR guidelines.

Request for a quote

GEMONE

Belgium

Verify if machines are utilized beyond contractual agreements. Invoice for additional usage or modify the contract to accommodate your customer's evolving requirements.

Request for a quote

ALPHATRONICS

Belgium

The StrongLine operating pillars are aluminum (3 mm thick) welded columns, standard powder coated anthracite (RAL 7016), have a sturdy base plate. The StrongLine pillar is availlable in heights from 1.2 and 1.5 meters for vehicles, 1.8 meters for pedestrians and 2.4 meters for trucks. These operating pillar can be equipped with 1 or more cutouts for mounting hardware modules and feature a door on the backside for accessibility of the components.

Request for a quote

ALPHATRONICS

Belgium

An operating column is different for every application, which is why we invested a lot of energy in the design of our SmartLine modular column. The SmartLine operating column consists of anodised corner profiles and aluminium painted side panels. Because an operating column helps determine the look of your service, we offer you the option of personalising your column. The front panel of the operating column is custom-made with specific cut-outs for the installation of your components (displays, readers, scanners, printers, payment terminals, etc.).

Request for a quoteResults for

Monitoring and control equipment - Import exportNumber of results

14 ProductsCountries

Company type