- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- breading machines

Results for

Breading machines - Import export

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

Our machine is used in bagel, roll, sandwich and hamburger breads. Machine settings can be made on PLC and digital display. These settings are saved in the recipe and do not want to be re-adjusted in product change. Machine chassis is made of 304 Cr-Ni sheet metal. It has the feature of spraying the desired amount of water, eggs, slurry and molasses on top of the products in the flat tray or molded tray. At the same time, it can sprinkle the desired amount of granular materials such as sesame, bran, kernel, rye on the products on the flat tray or molded tray. It is simple to use and clean.

Request for a quote

DAMS MACHINE

Turkey

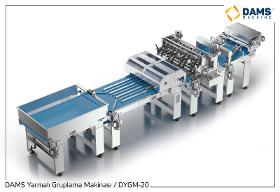

Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed. The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8). Here, the products are placed between the product pushers of the packaging machine with the help of a push rod. Product pushers take products to the enveloping unit and allow them to be packaged.

Request for a quote

DAMS MACHINE

Turkey

GENERAL CHARACTERISTICS Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed. The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8).

Request for a quote

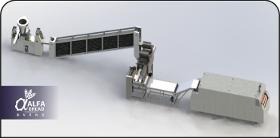

ALFA BREAD

Turkey

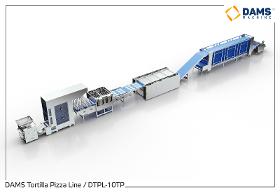

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

FERPLAST SNC

Italy

TABLE MONOBLOC SEALER WITH MANUALLY OPERATED SEALING BAR AN INCORPORATED ROLL HOLDER The SP 600 is equipped with sealing bar with NI-CR wire for simultaneous cutting and welding of the film. Allows to obtain a polyethylene or polypropylene bag, perfectly welded and trimmed, using the normal fold film. Suitable for use in laundries, shirt factories, the textile sector in general, but is also suitable for the food sector for the packaging of the bread. Operation: Place the coil with the open side facing the operator Insert the open-film blade between the two flaps Unroll the film to the desired length Lower the sealing bar and cut the bag Enter the product in the bag and make the welding of the side remained open.

Request for a quote

DAMS MACHINE

Turkey

It can cut sandwiches and hamburgers, flatbread, bagels, baguettes and similar products. It is used in the slicing (cutting) process of sandwich and hamburger breads before packaging. The slicing machine has wheels and can be taken anywhere easily. The chassis is completely chrome nickel. Used strip blade, easy to disassemble and install. The surfaces that the product comes into contact with are made of tape suitable for food. Product feeding is done manually.

Request for a quote

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program.

Request for a quote

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quote

DAMS MACHINE

Turkey

Roll Bread Packaging is done one by one. Thanks to the touch screen and PLC, there is easy access and intervention to the package size of the product, intelligent eye photocell adjustment and machine speed. Our Machine has intelligent motor system servo motor automation. There is a product control sensor that prevents the Roll Blower or other products from being jammed during packaging. During packing, the packaging does not crush the bread. If the location of the plant is not suitable, the intelligent eye sensor stops the machine. The machine is also made of 304 quality stainless chrome-nickel metal suitable for all surfaces that contact with the product and environmental protection covers. Our machine has been produced on the product in accordance with the operation of the device which outputs information such as date of production-serial number expiration date. This machine is optional. Emergency Stop has been put in place to provide user and machine security.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

1. Double frequency converter control, the bag length can be set and cut, no need to adjust the air, one step in place, saving time and film. 2. Man-machine interface, parameter setting is convenient and quick. 3. Fault self-diagnosis function, the fault display is clear at a glance. 4. High-sensitivity photoelectric eye color tracking, digital input sealing and cutting position, making the sealing and cutting position more accurate. 5. Temperature independent PID control, better suited to a variety of packaging materials. 6. Reciprocating end seal mechanism, the seal is more firm, and the seal cutter has no loss. 7. End sealing angling device, the bag shape is more beautiful, and the product grade is improved. 8. Positioning stop function, no sticking knife, no waste film. 9. The transmission system is simple, the work is more reliable, and the maintenance is more convenient. 10. All control is realized by software, which is convenient for function adjustment and technical upgrade.

Request for a quote

PKO-SURA COMPANY

Russia

The machine is intended to knead various types of high viscosity dough at confectionery and bakery enterprises: •gingerbread dough; •dough for doughnut products; •dough for sugar cookies; •dumpling dough, etc. The dough dish overturns through 120 degrees to unload the dough. All dangerous points of the machine are guarded. When the cover is open, the vane drive motor is automatically shut off. The feature of the dough-mixer is its powerful Z-shaped blades of stainless steel that enable to knead the tight dough gently. A variable frequency drive is used for smooth change of the blade rotation speed that makes it possible to use the machine for kneading crumpet dough.

Request for a quote

ALFA BREAD

Turkey

Full set of Arabic pita bakery equipment that you need to start producing perfect Arabic pita bread Fully automatic Lebanese bread production line Arabic pita bread machines include dough kneading machine dough proofer x 2 dough sheeter Oven Cooling conveyor belt Arabic pita bakery production capacities can range from 2000 to 12.500 pcs /h Lebanese bread line warranty 100% Automatic Arabic pita bread production line is designed to fit big and small production spaces Free training on how to make Arabic bread and free installation Full after-sales service for more details about Arabic pita bakery equipment www.alfabread.net 00905527066558

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

Spiral kneading machines are commonly preferred by bakery and pastry shops in order to shorten the usual kneading time. Also homogenous dough mixture is obtained thus volume of bread becomes even bigger. Machine can be worked as manual and automatic cycle with two programmable timers. The bowl, spiral arm, bar are made of stainless steel. The bowl can be rotated in reverse motion. Machine works as silent via belt transmissions of main power. It is a mobile machine and the wheels have locking system. Optionally, the temperature measuring unit may be added. process and allows to remove the bowl by user. The bowl is fasten to the mixer`s body with a locking system. By the way kneading standardization is always assured. The other specifications of removable bowl mixer are as follow: stainless steel bowl, knife and spiral hook, automatic and manual control, silence in mechanical system and power transfer, mechan-ical system and security system according to CE standards.

Request for a quote

SAMI KAMMAZ OVENS

Turkey

Arabic bread production line (automatic bakery) is a fully automatic production line, from mixing ingredients to cooling bread through several successive machines, and bread is known as Arabic bread, Lebanese bread or Syrian bread, and it has spread in recent times all over the world because of its advantages and positives . Basic components of the line: - Dough Fork Mixer - Dough Basins. - Dough Divider. - Primary Proofer. - Dough Flattener. - Final Proofer. - Tunnel Oven. - Cooling Conveyor. - Air Compressor. - Electrical Control Panel.

Request for a quote

ARODO - PREMIUM POWDER PACKAGING

Belgium

At some point in every production process, a machine breaks down or a component no longer works (properly). Our goal is to ensure that these moments are as short as possible, which is why you can contact our support team in four languages, 24 hours a day and 7 days a week. In 98% of cases, the line will be operational again on the same day.

Request for a quoteResults for

Breading machines - Import exportNumber of results

30 ProductsCountries

Company type