- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- convenience food equipment

Results for

Convenience food equipment - Import export

KASAG SWISS AG

Switzerland

Special equipment, production aid, pipeline construction, assembly In a dynamic market environment, new constructions, modifications, production expansions and the potential for process optimization not fully exploited, represent constant challenges, even in the food industry. The experts at KASAG support and accompany you in all your investment and maintenance projects in the food technology with design, engineering, manufacturing, pipeline construction and assembly. In addition, you will have access to KASAG’s knowhow in the areas of energy recovery (renewable energy) and pressure vessel construction. With KASAG as your partner, you can count on specialists on location.

Request for a quote

REINASAN BV

Netherlands

With this animation, we try to give a brief and clear explanation of our system for the food industry in a playful way. More details on this and possibly other Reinasan systems can be found here on Europages, our website and on our YouTube channel. We'd love to hear from you! Feel free to send us a message via this platform. Have fun watching!

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple barrel size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION One barrel feeding turn table One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system. 6 heads Diving filling nozzles Capping system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Servo conveyor system Herma head Simplified control panel Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

EACTECH®

Portugal

The equipment that guarantees total hygiene and safety control The Pass-120 Boot Sanitizing Station is a disinfection equipment that guarantees strict hygiene control of the operator's boots. With automatic soap dosing system and two rotating brushes 700 mm long and 170 mm in diameter. This equipment is very easy to implement, has an ergonomic design and an input and output system controlled by photocells. The most competitive price-quality ratio on the market Automatic soap dosing Entry and exit step controlled by photocells 700 mm long rotating brushes Footwear sanitized in milliseconds Stainless steel construction Cabinet with lock for the disinfectant bottle

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 4 diving filling nozzles One bottles feeding rotary table Star capping system Caps feeding system One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

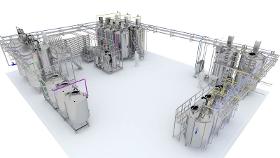

1,Specification •,Milk Double jackets cooling collecting tanks •,Chillers. •,Storage feeding tank •,Processing section •,Cheese press to mold machines •,Mozzarella cheese making machines •,Vacuum cooker cream cheese making machines •,Rotary bottles washing system •,Milk, yogurt and cheese filling, sealing and capping machines •,Fermentation room. •,Compact design •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple ointment viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quote

WHITE STEEL GMBH

Germany

1,Specification •,CIP Unit •,Storage tanks •,IP56 Control panel •,Piston Homogenizer •,Double jacket mixer Preparation unit •,Pasteurizer machine •,Butter molds melting tank •,Pasteurization Holding tubes •,Swing bend panel •,Lobe pumps PL150 •,End product storage tank with double jacket “ heat and cooling system •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quote

WHITE STEEL GMBH

Germany

SPECIFICATION Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

CADA and HMI with a touch screen system Scrapers; PTFE food grade Teflon Pneumatic valve pneumatic system Cheese vacuum cooker machine; Double jacket, vacuum, pressure atmospheric system Compact design Capacity depends on the product type Cooker machine is equipped with an Electro pneumatic opening and closing system High homogenization system with steam injection valves Filtration system mechanical filter, to eliminating any unwanted residues. Sterilized Air pressure Transferring system. Buffer double jacket storage tank has been designed to maintain preserve and transfer the product to the filling machine Rotary filling sealing and capping machine sterilizing UV light integrated. Servo conveyor system Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

BARED SRL

Italy

The hyperfiltration plant (commonly known as reverse osmosis) allows the removal of a part of water by a semipermeable membrane and the action of a high pressure. The membrane is made of an organic material (polymer), with thickness of few microns, and supported from another organic material (supporting polymer). For the oenological application of the reverse osmosis, Bared use spiral membranes. Possible application of this plant is product concentration at various percentages: · max sugar recovery (up to 99%) · partial recovery (up to 60%) · concentration of coloured matter · partial or total rejection of acidity and salts.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to realize separating and grind process at the semolina passages in the flour diagrams, this process increases the yield of flour and consumes less energy comparing to other grinders

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is designed to enrich and classify semolina in flour and semolina mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to convey the granular and grinded products horizontally for collecting, distributing, mixing and tempering processes

Request for a quote

VCSP LTD

United Kingdom

VCSP's vibratory conveyors represent the pinnacle of innovation in material handling. Designed for efficiency and precision, our conveyors are tailored to meet the unique challenges of various industries, from food processing to pharmaceuticals. At the heart of our design philosophy is the user's need for rapid, gentle, and accurate material transfer. Our conveyors ensure minimal product degradation, making them ideal for delicate items. The energy-efficient design reduces operational costs, while the modular build allows for easy customization and scalability. Crafted using food-grade materials, they prioritize hygiene, ensuring that products remain uncontaminated. Specialized surfaces further facilitate thorough sanitization, addressing allergen and cross-contamination concerns. With VCSP's vibratory conveyors, businesses not only benefit from increased production efficiency but also achieve compliance with stringent industry regulations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018, FDA, HACCP, CE, UL SPECIFICATION HMI, SCADA System. Centrifugal pumps. CIP System. Apparent piping and extension system. ALFA LAVAL pasteurization gasketed plates. Diaphragm steam valves Copper plates heat exchanger. PT100 Sight glass. Our machine has been design to pasteurize Milk, Yogurt, Ayran and Juice. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple product viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION HMI and SCADA with touch screen system Mixer tank with raw material vacuum sucking technology Can handle multiple viscosity from high to low Double jacket mixer tank for heating and cooling system with pressure and vacuum technology Product certification transferring pump Flowmeter system Exchangeable blades; multiple blades types and design has been manufactured to conform the product types and textures Piping gel cooker machine; Time and speed can be adjusted up to the product needs Automatic product transfer system can be managed with the PLC screen Buffer tank transferring system; cooked products will be transferred from cooker by a homogenizer sucking system Homogenizer with a compact design; with exchangeable heads (conforming the product type).

Request for a quote

WHITE STEEL GMBH

Germany

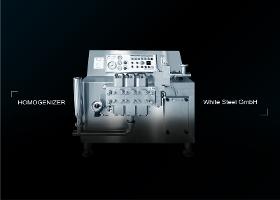

DESCRIPTION High stability on high capacity. Usually used for mayonnaise, ketchup, dairy product, milk and more… Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Permanently mixing Substances in a liquid Capacity from 16 to 16000 gph Compact design It is A3 certified and is electrically pre=disposed for ULCSA Pretested for quality control and stress test Manual Electric control panel 3 steps treatment for more product stability during subsequent treatments and storage Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quoteResults for

Convenience food equipment - Import exportNumber of results

21 ProductsCountries

Company type