- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- corrosion tests

Results for

Corrosion tests - Import export

IGUS® GMBH

Germany

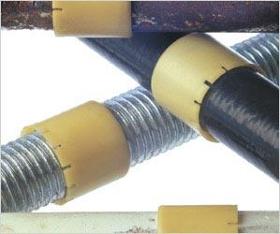

iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: When to use iglidur® PEP plain bearings? When a low-priced plastic plain bearing system is required When freedom is required from shaft material and shaft surface For the protection of expensive and sensitive shafts For extraordinary wear resistance with rare and slow movements. For constantly low coefficients of friction When freedom from corrosion is desired When not to use them? For high surface speeds iglidur® J For high loads iglidur® G iglidur® Q For high temperatures iglidur® V400 iglidur® X iglidur® Z When low-clearance bearings are required iglidur® P iglidur® X Maintenance-free plain bearings usually distinguish themselves by their ability to glide free of lubricants without any further additional layer on the shaft. In these systems it is obvious that shaft materials are as important as the bushings. igus® blazes a new trail with an enclosed and maintenance-free plain bearing concept. iglidur® PEP is an entirely novel lubricant-free plastic plain bearing system with an inner and outer ring. Special feature: The running partner is determined by the inner ring and for the first time, the material and surface finish of the shaft are insignificant. Even thread, rust or scratches do not affect the long-term reliable function. By the specification of the gliding partner and extensive series of tests, the long-term behavior of the bearing system can be precisely forecast. With the PEP polymer plain bearing, the inner ring rotates with the shaft like in ball bearings Relative movements of the shaft to the bearing are dispensed with. This protects the shaft surface from wear and saves costs. Another plus point: Even the most sensitive or unusual materials for the rotating shaft can be used with these new polymer bearings. The PEP polymer bearings are thereby absolutely free from material-dependent corrosion. Wear resistance The wear test results are absolutely convincing with loads up to 5 N/mm². Here the PEP polymer bearings attain values that are virtually comparable with those of the most wear-resistant plastic-steel bearing systems. An exceedingly satisfying result when you consider the costs saved by dispensing with the otherwise essential surface treatment of the shaft. The constantly low friction-coefficient level is also an advantage for the user. As the glide partners are fixed by the defined system, their tribological data too are accurately predictable. The coefficients of friction of the lubricant-free bearing are not determined any more by the shaft materials or surface conditions. If necessary, the coefficients of friction can be further lowered by additional minimum lubrication. Detailed test information with a wide range of lubricants are available and can be had from igus® on request. iglidur® PEP bearings operate independent of the shaft material. iglidur® PEP bearings consists of an inner and outer bearing. X = Load [MPa] Y = Wear [μm/km] A = PEP B = Combination 1 C = Comb. 2 D = Comb. 3 E = Comb. 4 F = Comb. 5 G = Comb. 6 H = Comb. 7 A1 = Wear of the outer bearing B2 = Wear of the inner bearing Fig. 02: Wear tests of various material combinations, p = 0.75 MPa, v = 0.3 m/s X = Load [MPa] Y = Wear [μm/km] A = iglidur® J B = iglidur® PEP Fig. 03: Wear of the iglidur® PEP bearing dependent on the load, v = 0.3 m/s iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: Dimensions according to ISO 3547-1 and special dimensions

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Leak detector high detection sensitivity for pressurised piping and containers, e.g. on compressors, steel bottles, fittings, shut-off valves, breathing devices, oxyacetylene gas and inert-gas arc welding devices, Bunsen burners, valves, screw fittings of compressed-air lines etc. Suitable for compressed air, refrigerant, acetylene, butane, natural gas, carbon dioxide, gaseous oxygen, propane, town gas, nitrogen, hydrogen and, ammonia Suitable for checking the safety of systems with combustible gases and for avoiding financial losses through unrecognized leaks Advantages and benefits Frost-proof to -15°C Saves energy and warns of gas loss Contains corrosion protection inhibitors Tested by the DVGW in accordance with DIN EN 14291 Non-combustible Economical in use

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

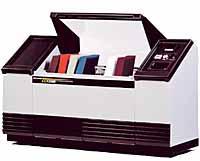

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

MERECS ENGINEERING GMBH

Germany

Development and construction of test systems for environmental simulation, i.e. climate and temperature tests as well as corrosion tests (e.g. MEMS testing and automotive durability tests on tilt sensors, inclination sensors, inertial sensors, inclination sensors, automotive parts and many more). - Adjustable humidity - Typical temperature ranges are -72 to + 120°C - Parallel testing and calibration of more than 100 DUTs simultaneously per test run - Various interfaces to the DUTs can be switched like CAN, LIN, Flexray etc. - Database connection and automated data analysis using Microsoft PowerBi can be added.

Request for a quote

PJM MECHANICAL CO.,LTD

China

SLA500 is new design for solar thermal tower power station and high concentrated PV. To meet the mirror panel drive performance, such as the rigidity, position precision, the inside limit switch is develop by POWER JACK MOTION in patent. It can help customer adjust the angle following customer’s solar tracker. All metal structure design can meet the harshest environments. Details Data: Motor Voltage: 24V DC (stepper motor) Max Load: 5500 N Max Static Load: 10000N Max Overturning Moment: TK more than 5N.M Axial Rigidity: 2000N Standard Stroke: From 100mm to 1000mm Speed Range: 1.2mm/s Transmission Precision: less than 0.35mm Reset Precision: less than 0.2mm Transmission Efficiency: More than 60% (ball screw type) Corrosion Protection: Salt spray test more than 480 hours Protection Class: IP65 Mechanical Life: More than 20 years Sensor Type: Hall Sensor

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PJM MECHANICAL CO.,LTD

China

Details Data: Motor Voltage: 24V DC (stepper motor) Max Load: 5500 N Max Static Load: 10000N Max Overturning Moment: TK more than 5N.M Axial Rigidity: 2000N Standard Stroke: From 100mm to 1000mm Speed Range: 1.2mm/s Transmission Precision: less than 0.35mm Reset Precision: less than 0.2mm Transmission Efficiency: More than 60% (ball screw type) Corrosion Protection: Salt spray test more than 480 hours Protection Class: IP65 Mechanical Life: More than 20 years Sensor Type: Hall Sensor

Request for a quote

M.E.G.A. SPA

Italy

A stateoftheart ISO 17025certified laboratory is an indispensable part of any company whose aim is to supply materials with excellent mechanical properties. Mechanical tests, NDE tests, micrographic examinations and ASTM A262 corrosion tests are carried out inhouse by qualified and certified personnel.

Request for a quote

INVITRO-CONNECT GMBH

Switzerland

INVITRO-CONNECT GmbH offers various test strategies without animal testing for examining skin Corrosion: - OECD 435 - Skin Corrosion : "In Vitro Membrane Barrier Test Method for Skin Corrosion" (Corrositex): The Corrositex® assay is a standardized and quantitative in vitro test developed as a replacement for the dermal corrosivity rabbit test. The Corrositex® assay is presently the only in vitro assay approved by the U.S. Department of Transportation for testing potential corrosive materials and assigning packing group categories. For more information please contact INVITRO-CONNECT GmbH for assistance in developing specialized protocols for your test materials. INVITRO-CONNECT GmbH: Fast Project Execution: personal - competent - reliable --> contact@invitro-connect.com More than 80 test laboratories - Product safety - Regulatory service - In vitro tests - All OECD tests for pharmaceuticals, chemicals, medical devices and cosmetics - Study monitoring, MSDS etc.

Request for a quote

INVITRO-CONNECT GMBH

Switzerland

- OECD 431 - Human Skin Corrosion: "In Vitro OECD 431: Reconstructed Human Epidermis Test Method, in vitro Test - Skin Corrosion in the regulatory hazard classification and labeling context is defined as the production of irreversible damage to skin, generally evident as necrosis through the epidermis and into the dermis, following a defined chemical exposure. The In Vitro Skin Corrosion Test is an in vitro, non-animal test designed to identify those chemicals and mixtures capable of inducing skin corrosion (UN GHS Category 11), and in some cases to partially subcategorize corrosives into UN GHS Sub-Categories 1A or 1B and 1C (ie., the current test methods do not effectively discriminate between UN GHS Sub-Categories 1B and 1C). For more information please contact INVITRO-CONNECT GmbH for assistance in developing specialized protocols for your test materials. INVITRO-CONNECT GmbH: Fast Project Execution: personal - competent - reliable --> contact@invitro-connect.com

Request for a quote

BÜCHI AG

Switzerland

Corrosion testing requires the realistic simulation of the process environment. These environments often include HPHT (high pressure high temperature) conditions. Thanks to our proprietary designs and the use of high-performance materials our industry leading HPHT corrosion testing autoclaves are suitable for the most challenging corrosion testing applications. We have worked jointly with customers from various industries such as upstream and downstream oil & gas, petrochemicals, steel, nuclear and conventional power generation, inspection, certification and testing to design, engineer and manufacture customized corrosion testing solutions for their individual applications.

Request for a quote

OFFSHORE QUALITY CONSULTANT SERVICES (HK) LTD.

Hong Kong

Our own laboratory can perform the following test: 1. Accelerated Weathering Test . 2. Environmental Temperature and Humidity Test. 3. Corrosion Resistance Test. 4. Transportation Test. 5. Color Assessment. 6. Precision Dimensional Measurement. 7. Metal Hardness Verification.

Request for a quote

ERC ADDITIV GMBH

Germany

3-zones corrosion protection for safe wintering and seasonal shutdown of all vehicles, machinery and equipment powered by gasoline. - Extreme protection against corrosion - Cleaning of the fuel system - Stabilization of the fuel THE EFFECT: A selection of highly active substances with an excellent corrosion and aging protection, and detergent of a new generation for a clean fuel- and injection system. MPULSER 3-zones corrosion protection was tested in a corrosion test of practical relevance in terms of its stabilizing, anti-corrosive properties by the independent institute Tec4Fuels GmbH. The results were faced with 4 comparable market products. THE ADVANTAGES AT A GLANCE: - Extreme protection against corrosion in the whole fuel system (in watergasoline- and gas- /air zone). Even with an existing water phase. - Cleaning of the fuel- and injector system – in consequence power recovery by the dissolution of formed deposits / combustion residues

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

VALENO Stretch Film combines the tried-and-tested corrosion protection afforded by EXCOR VCI with the specific properties of a stretch film. VALENO Stretch Film is a universal medium for the shape-hugging wrapping of merchandise stacked in open containers and the secure bundling of shaped pieces and tubing, while also providing a protective skin for metal parts and coils. Its smooth outer surface prevents wrapped merchandise packages from adhering to each other and facilitates the handling of stretched packages. The VCI corrosion protection integrated into the polyethylene-polymer matrix of EXCOR VALENO Stretch Film is active on both sides. VALENO Stretch Film can be used both manually and in packing machines.

Request for a quote

PROTEC TRADING GMBH

Austria

English | Deutsch | Español | Português | Français | Italiano | Русский Visit our website for information in your language. Metallotion PROTEC CE15L+ Premium anti-spatter fluid with integrated degreasing effect, PROTEC CE15L+ helps keeping metal surfaces free from hot metal spatter during welding. Intended for application to workpieces, equipment, and tools. Suitable for steel, zinc-plated steel, stainless steel, etc. Silicone-free, non-flammable, and biodegradable. When using PROTEC CE15L+ customers benefit from increased productivity (no need for additional processing of the work pieces) and increased quality with spatter-free metal surfaces. Further advantages: Effective wet or dry - long-term protection; Perfectly suitable to be welded over; Ideal suitability for coating (e.g. galvanizing, painting, cataphoresis, etc.) With integrated corrosion protection; Tested and proven internationally.

Request for a quoteResults for

Corrosion tests - Import exportNumber of results

15 ProductsCategory

- Anti-corrosion products, chemical (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Industrial analysis laboratory (1)

- Measurement and control instruments (1)

- Petrol (1)

- Power Stations (1)

- Quality control and certification (1)

- Scientific research centres and laboratories (1)

- Silicones (1)

- Solar energy (1)

- Steels and metals - surface treatment and coating (1)

- Testing of products and materials (1)

- Vehicles, military (1)

- Welding, electric - equipment and supplies (1)