- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- evaporators

Results for

Evaporators - Import export

EC PLAZA

South Korea

Our company creates and seeks a healthy company culture, and is making efforts to promote the atmosphere that allows our employees to develop themselves in a pleasant environment under the conviction that “workplace should be a living place for their personal development and the realization of their dreams as members of society. Then, nowadays faced with a urgent issue, the reconsideration of company’s technological competitiveness through the advancement of semiconductor industrial structure, our company is moving towards its technological innovations according to rapid changes in technologies and the circulation of product cycles based on this conviction.4M Electro-Optics Co., Ltd. promises our customers that it will be a company of good ideas, wonderful memories, and excellent products at all times.

Request for a quote

PLANSEE SE

Austria

Evaporation boats made of tungsten, molybdenum and tantalum are available in many different widths, lenghts, material thicknesses and volumes directly in the Plansee Online Shop: www.plansee.com/shop. Special dimensions are available on request.

Request for a quote

PLANSEE SE

Austria

Evaporation coils are available in many different lenghts, diameters, coil lenghts and coil pitches. These resistance heaters with their very high melting points will bring practically any metal to the boil. At the same time, their high corrosion resistance and outstanding material purity prevent any contamination of the substrate. The range includes evaporation coils made of the following materials: — Grain stabilized tungsten (WVM) for the evaporation of aluminum — Tantalum — Molybdenum — Molybdenum-lanthenum (ML) for particularly long service lives

Request for a quote

EVAPTON HEAT EXCHANGER

Turkey

EV SERIES SHELL&TUBE EVAPORATORS RANGE FROM 20KW TO 1510 KW COOLING CAPACITY IN EVAPTON'S STANDARD CONDITIONS. THE REFRIGERANT SIDE CAN BE MANUFACTURED FROM 1 CIRCUIT TO 4 CIRCUITS. EV SERIES EVAPORATORS CAN BE USED WITH HCFC AND HFC REFRIGERANTS WITH MEDIUM TO HIGH SYSTEM PRESSURE (30-45 BAR). EVA SERIES EVAPORATORS CAN BE MANUFACTURED BOTH IN STANDARD CATALOG SIZES AND IN THE SIZES REQUESTED BY THE CUSTOMER. EVERY EVAPORATOR MANUFACTURED IS CONTROLLED BY UNILAB LICENSE PROGRAM FOR CAPACITY AND PRESSURE DROPS AND TRANSMITTED TO THE CUSTOMER. EVS - SINGLE CIRCUIT EVAPORATOR EVD - DOUBLE CIRCUIT EVAPORATOR

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

For the thermal separation of a mixture a thin film is produced at the heated wall of a cylindrical or conical evaporator. A distribution ring on the rotor distributes the liquid evenly across the periphery. Then, the blades fitted at the rotor spread the liquid as a thin film of min. 0.5 mm over the heat transfer surface. The model concept for the flow in the thin film evaporator assumes that prior to each rotor blade a bow wave is formed. In the gap between the rotor blade and the heating surface, fluid is supplied from the bow wave of a highly turbulent area with intense heat and mass transport. This results in a good heat transfer performance even with viscous products. In addition, the formation of deposits is avoided and the intensive mixing also protects temperature-sensitive products from overheating.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The sample to be distilled is exposed only for a very short time to the heating substances because the film, created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. The evaporated product (operation pressures down to 103 mbar and temperatures up to about 300°C) has to pass a “short path” to the condenser only, which is located in the middle of the evaporator. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Evaporators in stainless steel can be heated by a heating jacket to higher temperatures with more heat transfer area for higher throughputs.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The medium which is to be distilled is exposed only for a very short time to the heating substances because the film, which is created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Alternative design versions in stainless steel for higher throughputs are available upon request. Please equire.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Rocket Synergy 4D is for drying single large volumes of solvent, from a few litres up to approximately 100 litres. The system can also be used for a single batch of up to 5 litres. Rocket Synergy 4D provides fast, safe evaporation for solvents with a boiling point of up to 165°C (DMF) and can easily dry aqueous samples. Automatic evaporation of volumes up to 100 litres Eliminates bumping or foaming Easy vessel manipulation with no glassware to handle Safe, easy product recovery and system cleaning

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Series 3 HT evaporator range from Genevac represents the ultimate in solvent removal technology. Genevac-014 A Solution for High Throughput Evaporation Genevac HT series evaporators are the ideal solution for parallel evaporation bottlenecks in high throughput and production laboratories having high performance and high sample capacities. The unique design of the multi-layer rotor ensures efficient use of valuable laboratory bench space as well as high performance and high throughput evaporation. This proven design has now been updated with the latest version, the Series 3.

Request for a quote

OKAWARA MFG. CO., LTD.

Japan

EVAPOR is a Spinning Cone Centrifugal Thin-Film Vacuum Evaporator specially designed for the concentration of heat sensitive, viscous and high value products. The spinning cone of the EVAPOR not only helps to prevent foam formation but also decreases the contact time between the product and the heating surface to less than one second at evaporation temperature as low as 35oC to further reduce the thermal impact and preserve maximum functionality of the product active compounds. The centrifugal design also helps the EVAPOR to achieve higher concentration level than traditional evaporators. Benefits Low-temperature evaporation and extremely short residence time result in an ideal equipment for heat-sensitive quality products Foaming is minimized by centrifugal force Able to produce concentrates with considerable higher soluble solids level and higher viscosity than traditional plate or tubular

Request for a quote

QUARZGLAS KOMPONENTEN UND SERVICE QCS GMBH

Germany

A quartz material / glass-encased, spiral-shaped, electrical heating coil with a large surface, which is mounted in a quartz material reflector shell with a handle, allows liquids to be heated indirectly by infrared radiation. This is used for the fast, economical evaporation or concentration of liquids. Due to this principle, only the surface of the liquid is heated very strongly, as the thermal radiation is absorbed even after shallow penetration, thus enabling gentle, uniform evaporation.In contrast to boiling evaporation, there is no loss of substance due to splashes from a moving boiling surface. Since surface evaporators are made exclusively from the material fused quartz / glass, it is possible to use the advantages of the material, such as good IR permeability, heat and heat change resistance, lowest electrical conductivity, exceptionally high chemical purity and resistance as a material. It complies with EC Directive 89/336 / EEC and EC Directive 73/23 / EEC.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

EVAPTON HEAT EXCHANGER

Turkey

EV SERIES SHELL&TUBE EVAPORATORS RANGE FROM 20KW TO 1510 KW COOLING CAPACITY IN EVAPTON'S STANDARD CONDITIONS. THE REFRIGERANT SIDE CAN BE MANUFACTURED FROM 1 CIRCUIT TO 4 CIRCUITS. EV SERIES EVAPORATORS CAN BE USED WITH HCFC AND HFC REFRIGERANTS WITH MEDIUM TO HIGH SYSTEM PRESSURE (30-45 BAR). EVA SERIES EVAPORATORS CAN BE MANUFACTURED BOTH IN STANDARD CATALOG SIZES AND IN THE SIZES REQUESTED BY THE CUSTOMER. EVERY EVAPORATOR MANUFACTURED IS CONTROLLED BY UNILAB LICENSE PROGRAM FOR CAPACITY AND PRESSURE DROPS AND TRANSMITTED TO THE CUSTOMER. EVS - SINGLE CIRCUIT EVAPORATOR EVD - DOUBLE CIRCUIT EVAPORATOR

Request for a quote

DANO FOOD-DELIBELGE®

Belgium

Made by removing 60 per cent of water from fresh milk, our evaporated milk is thick, creamy and a popular substitute for cream in desserts.

Request for a quote

DANO FOOD-DELIBELGE®

Belgium

Full cream evaporated milk made from fresh cow milk

Request for a quote

DANA EUROPE OU

Estonia

DANA Evaporated Milk is produced from fresh cow milk. We remove over half the water content of fresh milk through a heating process and then seal and preserve the product in 410 gr tins for a long lasting shelf-life. Our Evaporated milk is an unsweetened condensed milk. You would only need only to add water in the right amount to restore the product into regular milk. DANA Evaporated milk is a perfect additive for coffee and tea. Dana Evaporated Milk is favored in many countries including countries in the North Africa, Middle East as well as Latin America. Dana Evaporated Milk is a premium product that looks great on all supermarket shelves. The gross weight is 410 grams and the milk color is light cream with the light drab tone. It is packed in 410gr easy open tins. There are 48 tins in a carton. Product's fat content is 7.5% and Protein content 6%. Its shelf life is 12 months.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BUSS-SMS-CANZLER GMBH

Germany

Short path distillation is a thermal separation technology operating at process pressures in the range of 1 to 0,001 mbar. It lowers the boiling temperature and is an excellent method for gentle thermal treatment of heat sensitive, high boiling products. The short path evaporator consist basically of a cylindrical body with a heating jacket, a rotor and an internal condenser. The rotor creates a mechanically agitated, thin product film on the heating surface inside of the body. By means of gravity the product flows down in a spiral path, whereby the volatile portion of the product evaporates. The vapour passes by the shortest route and with practically no pressure drop to the internal condenser. The non-volatile portion reaches the lower part of the evaporator and is discharged through the bottom product outlet. The residual vapours and inert gases flow through the vacuum nozzle to the vacuum system.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

The SMS thin film evaporator type HYVAP serves the increasing demand of the pharmaceutical industry for continuous concentration of heat sensitive, viscous and fouling products. Hygienic design for the pharmaceutical industry The HYVAP is a horizontal thin film evaporator that allows easy access and inspection of the interior and controlled and reliable CIP cleaning. The technology of the HYVAP combines the proven advantages of our conventional horizontal thin film evaporators DKH with the following new features: • Cantilever rotor design • Comfortable rotor extraction • No bearing in product space • Mechanical seal in hygienic design • Electro-polished surfaces • Sight glasses for inspection during operation The new HYVAP DZH offers the hygienic design that meets current GMP requirements. The evaporator sizes range from 0.1 m2 for laboratory to 2.0 m2 for industrial applications. LP steam as well as hot water can be applied as heating media.

Request for a quote

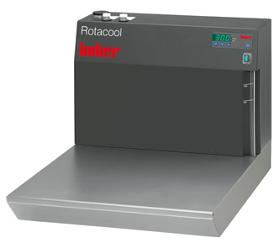

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

This chiller is unique on the global market due to its space saving L-form. The additional space required on the laboratory table is zero! Abracadabra: placed on rotary evaporator the RotaCool virtually disappears completely. The RotaCool is a product to provide a dedicated cooling service to all small bench top Rotary Evaporators. Solution for cooling of rotary evaporators Compact, space-saving design Additional extension plate Ideal for conventional rotary evaporators Robust stainless steel construction Easy operation with only three keys LED temperature display

Request for a quote

ANTHERMO GMBH

Germany

Tubes wound into a spiral shape Coaxial heat exchangers consist of two or more pipe coils, which are routed into one another and wound up in a spiral shape. The primary medium runs in countercurrent to the secondary medium. Fast temperature exchange This countercurrent design achieves a very rapid temperature transition with high efficiency between the liquids. Due to the spiral shape, the rapid temperature exchange between the liquids is achieved in a very small space. No cleaning or maintenance required Another advantage is the encapsulation of both liquids from environmental influences. There is practically no cleaning or maintenance effort due to pollution from the environment. The coaxial heat exchanger also does not require any seals that require maintenance. Condenser or evaporator function Coaxial heat exchangers can be used for both condenser and evaporator functions.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For fast determination of thermally-dependent interruptions in electrical circuits or components Avoidance of heat damage when soldering electrical components For heat protection of neighbouring components Shrinking of inner parts for removal of seized taper plugs, pins, plugs or bearing bushes Generation of shrink seats for assembly of inner parts For rapid temperature adjustment during materials testing For simulation of cold-starting conditions with motor-vehicle automatic starting systems Advantages and benefits Highly effective due to outstanding undercooling effect Excellently suited for simple cooling of parts Immediate cooling of smaller surfaces or parts down to –45°C depending on spraying duration Evaporates very quickly without residues Also provides good cleaning effect No negative affects on plastics and insulating materials

Request for a quote

KASAG SWISS AG

Switzerland

You state your requirements and send us the material properties. KASAG then configures the thermal and hydraulic calculations for the desired heat exchanger. The realization is implemented according to the available drawings or on the basis of a comprehensive engineering. KASAG offers all processes necessary for that, such as the orbital-welding process for manufacturing heat exchangers. With KASAG, you can be sustainably flexible.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

stainless steel*high shape

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

stainless steel*flat form

Request for a quote

ÁRIK 21 - AGRO KFT

Hungary

Parameter Specification Total Solids 72% min Fat 10% min Milk Solids Non-Fat 15% min Sucrose 45% min Protein 2% Vitamin A 700 mcg / 100g Vitamin D 120 mcg / L / 100g

Request for a quote

TMS INDUSTRIAL REFRIGERATION EUROPE B.V.

Netherlands

You may not have a drainage point for the water generated during the cooling cycle. It is possible to vaporize and eliminate the condensed water with the DWE Series Drain Water Evaporators. Multiple cooling systems operating in the same location can be connected to a single DWE unit, thus, providing you with a compact and low- cost solution.

Request for a quoteResults for

Evaporators - Import exportNumber of results

79 ProductsCountries

Company type

Category

- Heat exchangers (11)

- Air conditioning, aeration and ventilation equipment (10)

- Dairy products (7)

- Air conditioning equipment (5)

- Powdered and condensed milk (5)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Cooling towers (2)

- Houseware, steel (2)

- Milk (2)

- Pharmaceutical industry - machinery and equipment (2)

- Silicones (2)

- Ventilators and fans - industrial (2)

- Water extraction - systems and equipment (2)

- Boarding, metal (1)

- Ceramics, industrial (1)

- Chemical industry - machinery and equipment (1)

- Condensers (1)

- Driers, industrial (1)

- Environmental clean-up - machines and equipment (1)

- Erection and dismantling of industrial plants (1)