- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transmission belts

Results for

Transmission belts - Import export

ERO JOINT .TANALS

France

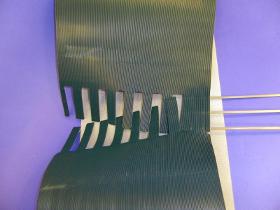

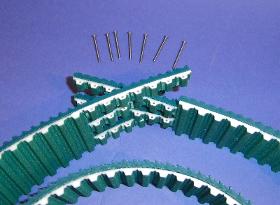

Exclusive Gates and Tanals The only power transmission belt with mechanical assembly The mechanical fastening system ERO Joint® - developed by Tanals - provide various possibilities to assemble belts on-site without having to disassemble pulleys or axes and to release the transmission. ERO Joint® and ERO joint® Ultimate are developed for and with Gates by Tanals. They offer unique solutions system for easy and fast repair of power transmission. The cutting shapes of the junction fingers have been engineered for maximum tensile strength and fatigue resistance of the Poly Chain® GT Carbon™ material. The power of Gates combined with the creativity of Tanals. Poly Chain® GT Carbon™ outstanding mechanical performance combined to patented innovative solution ERO Joint® Ultimate offer the only transmission belt with mechanical assembly whose performances equal those of all other endless belts on the market. A sustainable solution able to replace any rubber belt.

Request for a quote

ERO JOINT .TANALS

France

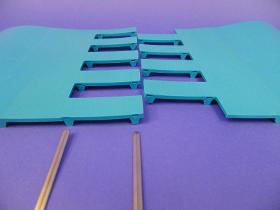

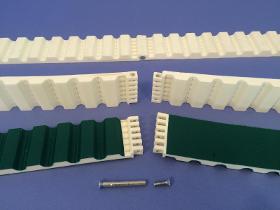

The mechanical fastening system ERO Joint® is available in conveyor belts with a thickness over 1mm. The assembly is made by threading of 3 transversal pins (stainless steel or polyacetal pins can be used). ERO Joint® splice is integrated into the conveyor belt, with no structural, width and colour changes. Tensile Kevlar cord can be embedded in Polyurethane upon request. Anyway using ERO Joint® conveyor belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® conveyor belts are easy to assemble.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ERO JOINT .TANALS

France

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With the hinge pin mechanical fastening system ERO Joint® HP, you will optimize your production downtime by reducing the repair time. Mechanical strength and lifetime are higher than any other mechanical fastening systems. Mechanical resistance and elongation are equivalent to welded belts. TENSIONING TOOL FOR ERO JOINT® HP Alternatives Spiral seams The mechanical spiral seams system is also very easy to assemble as ERO Joint® HP but its mechanical resistance is poor. Pin Joint The mechanical Pin Joint system is more difficult to assemble than ERO Joint® HP. The mechanical resistance is also lesser than ERO Joint® HP.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERO JOINT .TANALS

France

Exclusive Gates and Tanals The only power transmission belt with mechanical assembly The mechanical fastening system ERO Joint® - developed by Tanals - provide various possibilities to assemble belts on-site without having to disassemble pulleys or axes and to release the transmission. ERO Joint® and ERO joint® Ultimate are developed for and with Gates by Tanals. They offer unique solutions system for easy and fast repair of power transmission. The cutting shapes of the junction fingers have been engineered for maximum tensile strength and fatigue resistance of the Poly Chain® GT Carbon™ material. The power of Gates combined with the know-how of Tanals. Poly Chain® GT Carbon™ outstanding mechanical performance combined to ERO Joint® provide the only existing transmission belt with mechanical assembly. The only existing transmission belt with mechanical assembly, a unique solution on the market. Suitable for all HTD installations.

Request for a quoteResults for

Transmission belts - Import exportNumber of results

7 ProductsCountries

Company type

Category