- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt

Results for

Belt - Import export

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 485604 Belt Specification Woven belt Model type: C (Customised) Dimensions: approx. 40.0 mm wide Material: Acrylic Colour: olive/brown/olive Property: non-elastic Packaging: rolled

Request for a quote

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 6917-15 Belt Specification Woven belt Model type: S (Standard) Dimensions: approx. 30.0 mm wide Material: Spun rayon Colour: skin tone Property: non-elastic Packaging: rolled with core

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper haul-off timing belts are made with polyurethane or neoprene timing belts that are finished with many different kinds of coatings. They are used for conveying foils in bag forming, filling and sealing machines as well as numerous other conveying tasks. The extensive range of designs offers the optimal solution for any transport task and application, e.g. with smooth or vacuum-processed surface, finished according to individual specifications, and with many different coatings. Timing belts - Polyurethane molded timing belts - or neoprene molded timing belts Tension cords - Steel - Aramid - Polyester Coatings - PU yellow - Linatex - Various elastomers - Silicone

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU molded timing belts (form belts), which are cast in special molds, are made of abrasion-resistant polyurethane and high-strength steel cords (or aramid cords). The cast PU timing belt is an exact replica of its mold. Consequently, high pitch accuracy along the entire length of the belt is realized. They are particularly well suited for smooth running and high speeds. By combining high-quality materials and this modern production method, the resulting timing belts exhibit supreme mechanical, chemical and physical properties. Mechanical properties: Low longitudinal tolerance Longitudinal stability, negligible elongation Form-fit, synchronous running Low noise High abrasion resistance Favorable performance-weight ratio Chemical properties: Good ageing resistance Operating temperature range from -30°C to +80°C Resistant to simple oils, greases and gasoline Applications All types of drives Office machines Textile machines Wood-processing machines

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

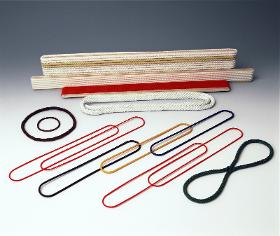

Round belt catalog

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Our endless turned round belts are wound either out of one homogeneous strand or one cord and spliced endlessly without thickening. For special applications, it is possible to vulcanize the inner splice or to make a special splice based on our in-house engineering methods. This increases the tensile strength by up to 60%. In elastic types, the core is welded. In view of their special structure, twisted round belts exhibit very quiet running properties, are extremely flexible and, thus, make possible very small minimum pulley diameters of 3x belt diameter. For several types, speed up to 70,000 rpm is possible; however, the speed of 60m/s should not be exceeded. Elastic types: PU, Vulkollan Semi-elastic types: PA.6, Set-Polyester, Nylon, HE Types with limited extensibility: Polyester, Nomex, Nomex-PTFE, Polyester-PTFE, Kevlar/Twaron, PA.6 anti-static, PBO

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Endless extruded round belts Our endless extruded round belts are ideal for low power requirements. They are elastic power transmission elements that do not need cost-intensive tensioning devices. In view of the special production process, they do not have any welding seams or terminal connections and run very smoothly. Moreover, they allow a minimum pulley diameter starting from 5.5 x belt diameter. Our types E80, V75, C70 and P82 are made of specially selected and dynamically tough materials. In addition, type E80 also is antistatic to a limited extent and has a resistance value of about 106 Ohm; thus, it is excellent for use in electronic devices and chip production. Available diameters: 1.8mm - 7mm Available lengths: 40mm – 1,610mm Temperature resistance: -20°C - +160°C Coefficient of friction: 0.35µ - 0.9µ* Maximum tension: >100N

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

We have a complete range of polyurethane round belts for conveying and power transmission applications. PU round belts, extruded in open lengths, are homogeneous round profiles that can be welded for use as high-quality power transmission and conveying elements. Our stock mainly comprises solid profiles with a smooth or slightly roughened surface and hollow profiles for nipple connections. Several types have FDA/USDA approval and comply with EU Directive 2007/19/EC. Although we generally produce in open lengths, we can also produce all belts according to your specifications. Our round belts convey a wide range of products such as foodstuffs, glass, roof tiles, PC boards and many more. The standard range of round belts is rounded off with aramid, polyester or glass-fiber reinforcements. If an appropriate quantity is purchased, we also produce special types with PES or aramid reinforcements.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

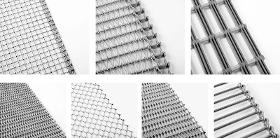

The Dutch Lesjöfors company Tribelt specializes in developing and manufacturing metal conveyor belts. For more than 70 years, the company has solved problems for customers in many different fields across Europe. We also manufacture sprockets, customized for the design and in the number your application require, its’ tension forces and surrounding environment.

Request for a quote

F.E.S. GMBH

Germany

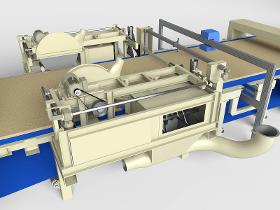

Hinged belt filters, also known as folding belt filters, are used for cleaning contaminated coolant fluids in metal processing and rolling mill applications. Cleaned coolant fluids have longer service life, improve the surface quality of workpieces or rolled goods, and assist in heat dissipation at the processing or forming site. Advantages: High throughput capacity No backflushing required during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure flushing system Cost-effective Operation: The F.E.S. hinged belt filter incorporates a circulating plastic filter belt to meet the filtration requirements without disposal issues. A filter belt cleaning device is located below the filtrate discharge chamber. The opening and closing of the chambers are controlled by two pneumatic cylinders. The self-locking toggle lever mechanism keeps the chambers closed even in the event of a loss of compressed air.

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The trimming saw is installed downstream of the last surface-layer mat former, cutting the strand mat precisely to the required width. Two motor-adjustable saws, one each located on either side of the belt, cut the strand mat to the dened width. The trimming waste is discharged through a hopper and recycled to the mat former bins. Features Motor-adjusted saw blades incl. distance measurement Movable mat edge retainers to ensure high-quality cuts Lateral pressure rollers ex saw compact and smoothen the mat edge Movable extraction system adjustable to mat thickness Advantages Recipe-related adjustment of all adjustable axes Eective strand extraction

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The mat trimming saw cuts the precompressed mat precisely to the width required. Two motor-adjustable saws, one each on either side of the belt, cut the bre mat to the dened width. The trimming waste is disintegrated and may be recycled to the production process. Features, function Modular design Motor-adjusted saw blades incl. distance measurement Max. trimming waste of 420 mm on either side Max. mat height ex prepress 360 mm Integrated hogger including extraction stub to remove the trimming waste Extraction stub at the saw blade

Request for a quote

FORBO SIEGLING GMBH

Germany

With Siegling Transilon, the gap is often bridged between the classical conveying function from “A” to “B” and an active function in the production process. For example, in the textile industry our processing belts stack thin layers of web, in large bakeries they form balls of dough, in the wood industry they compress chip mat in the pre-press, in dairies milk is coagulated on the belts to form cheese. Here are just a few examples of process operations. Cross-lapping of web layers in the nonwoven industry. High production speed and acceleration of masses while the web is guided directly between the belts places extremely high demands on the processing belts.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus drag belts are special developments with superior mechanical and electrostatic characteristics which make conveying and handling electronic components more efficient and safe: due to the HC or HC+ characteristics (highly conductive or highly conductive plus) the static electricity that builds up in the conveyor can be discharged better in a controlled manner; due to simplified accumulation with TT types which produce consistently low friction coefficients on the top face and underside; due to a particularly high level of abrasion resistance, as well as stable, lint-free belt edges. Siegling Extremultus drag belts are supplied endless, prepared for splicing, or as roll material.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus tangential belts have been optimized to suit the diverse range of yarn-manufacturing processes and different drive shapes. They play a major role in ensuring consistently high yarn quality and efficient production due to the following characteristics: superior abrasion-resistant coatings made of elastomer G or polyurethane with constant friction coefficients and long service lives; optimized surface pattern for the spindle and motor side; less belt creep and excellent levels of power transmission; energy-efficient polyester or aramide tension members; polyamide sheet tension members with good damping characteristics for high levels of effective pull; low-noise and low-vibration operation; antistatic finishes. Siegling Extremultus tangential belts are supplied as roll material, prepared for splicing or have already been spliced. With our splicing methods, homogeneous, reliable splices can be made efficiently while belts are still on the machinery.

Request for a quote

FORBO SIEGLING GMBH

Germany

Compared with other power-transmission products, Siegling Extremultus power-transmission belts stand apart because they offer a better level of efficiency (≥ 98 %), high level of synchronization accuracy and are uncomplicated to handle. They also offer the following exceptional characteristics: -consistent and reliable speed and long service lives; -short take-up ranges, low creep; -good damping capabilities; -superb durability and reliability up to a capacity of 1850 kW. -capability to handle bevel and cone drives easily.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

V-belts / Power belts / Ribbed belts Catalog

Request for a quote

IMM MASCHINENBAU GMBH

Germany

The 72711 belt sander offers all benefits of the 72780 series but with only one side. It is made for heavy duty applications. For sitting or standing operation. Variable cutting speeds from 900 to 2,800 Rpm. Optionally with frequency converter.

Request for a quote

FORBO SIEGLING GMBH

Germany

In the manufacture and processing of boxes, Siegling Extremultus folder gluer belts play a key role in ensuring that the quality and productivity potential of the machinery is exploited to the full. Our range of types offers the right belt with specific characteristics for each application: due to tension-resistant tension members made of polyester or aramide fabric, polyamide sheet or elastic polyurethane; due to customizable grip with various functional layers that are kind to surfaces – also in FDA quality; due to constant grip and long service lives. Reliable splicing methods allow easy fitting of the belts in the machinery, therefore minimizing downtime

Request for a quote

AAAGILER GMBH

Germany

We offer sanding belts suitable for the following manufacturers of long belt, edge and profile sanding machines: CMC, Fein, Flott, Greif, Hessemann, Hess, Holzmann, Holzkraft, Johannsen, Kündig, Kuhlmeyer, Löser, Löwer, Niederberger, Quick Wood, Scheppach, SCM, Stähle, Vohbag and Wegoma. We also offer quality sanding belts suitable for the following manufacturers of hand sanders: AEG Powertools, Atlas Copco, Black & Decker, Bosch, DeWalt, Einhell, Festool, Fein, Felisatti, Flex, Hitachi, HOLZ HER, Kress, Löser, Makita, Metabo, Milwaukee, Peugeot, Ryobi, SKIL, Stayer and Suhner. And if you can't find what you're looking for in our standard range of abresive belts, we can also supply custom-made sanding / grinding belts.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

PVC conveyor belt 2-ply petrol, structure Supergrip

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

PVC conveyor belt 2-ply light blue, structure Längsrille

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

PU conveyor belt 1-ply white

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

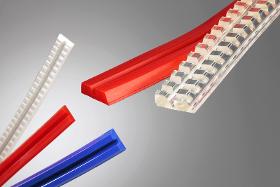

In our catalog for coatings, machining and profiles for belts, you will find all the different possible materials for coatings of belts. The possibilities for machining and amny examples for transportation cleats and profiles.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

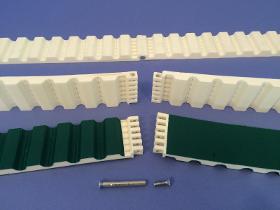

PU timing belts with easy joint as strong as a welded joint The easy joint timing belt fastener is the perfect solution, for a quick and easy mechanical endless connection of PU timing belts. Assemble without disassembling, without stopping your production line Replace your belts in few minutes without disassemble your hoods, pulleys, axis. Reduce your production downtimes. The method of mechanical assembly and fastening system easy joint offers unique solutions for easy and fast repairs of power transmission belts or conveyor belts. Pitches: H / T10 / AT10 / T20 / AT20 / 8M / 14M Standard: Polyurethane 90° Shore A grey Versions: Standard, PAZ, PAR Cords: reinforced with a Polymercord around the Pin in each tooth joint, arranged in parallel Width: from 10 to 150mm, (wide belts possible on request)

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper open-ended PU timing belts are made of abrasion-resistant polyurethane and high-strength steel cords or aramid cords and are available in open lengths. These timing belts are very suitable for synchronous conveying and positioning applications because they have very high flexibility and can be made with many different tooth shapes and materials; when combined with different tension cords, innumerable applications are possible. Keiper open-ended PU timing belts can be produced endless welded and by the meter in almost all lengths and widths. Based on this combination of high-quality materials and production methods, these belts exhibit outstanding mechanical, chemical and physical properties. Endless welded timing belts are available in any length. Welded PU timing belts primarily are used in conveying technology.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Round hook belts are the ideal solution for power transmission or conveying systems where several belts run on one shaft. Since they are easy to install, downtimes and maintenance costs can be reduced significantly. The hook belts only have to be inserted. Then the belt is joined to the hook and the second side of the hook is closed with pliers. Thus, there is no time-consuming and cost-intensive assembly work.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

PU V-belts run individually or alongside one another and convey products on slightly ascending or descending conveying systems without allowing the products being transported, e.g. boxes, tiles, glass slabs, cardboard articles etc., to slip. In addition, PU V-belts are used for driving live roller conveyors. Standard stock program: 75° Sh.A red 80° Sh.A transparent, FDA 80° Sh.A sky-blue, FDA 85° Sh.A green 90° Sh.A white Profiles 6x4 / 8x5 / 10x6 / 13x8 / 17x11 / 22x14 Smooth or notched

Request for a quoteResults for

Belt - Import exportNumber of results

366 ProductsCountries

- Germany (366)

- Bonn, Düsseldorf and North Rhine and Westphalia (60)

- Bremen and region (9)

- Frankfurt am Main and Hesse (8)

- Hannover and Lower Saxony (93)

- Leipzig and Saxony (2)

- Mainz and Rheinland-Pfalz (7)

- Munich, Nuremberg and Bavaria (7)

- Saarbrücken and Saarland (1)

- Schwerin and Mecklenburg-Vorpommern (16)

- Stuttgart, Freiburg and Baden-Wurtemberg (158)

- Weimar and Thuringia (5)

Company type

Category

- Conveyor belts (268)

- Transmission belts (15)

- Grids, gratings and wire mesh (15)

- Conveyor systems (14)

- Bearings - ball, needle and roller (6)

- Metallurgy and iron and steel industry - machinery and installations (4)

- Wood veneer - machinery and equipment (3)

- Leather Goods (2)

- Construction machinery (2)

- Goods handling systems, continuous (2)

- Grinding - machine tools (2)

- Industrial equipment hire (2)

- Machine tools, metal shaping - parts and accessories (2)

- Moulds, plastic and rubber industry (2)

- Straps, woven - industrial (2)

- Bags, briefcases and handbags (1)

- Abrasives, mechanical (1)

- Filtering equipment and supplies (1)

- 3D scanner (1)

- Alarms - security devices (1)