- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feeder

Results for

Feeder - Import export

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— dustproof closed compact device — is suitable for all free-flowing, free-flowing bulk goods — compact design saves space More Options: — explosion-proof design Power range 2000 - 4000 dm³/h 3000 - 100000 dm³/h 10000 - 160000 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Loss-in-weight feeder for powders and pellets — Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-3743 dm³/h 20-3743 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.) — Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation — Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 20-7610 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at low feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-489 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.) — Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates — Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20) Power range - Different versions 1-25570 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

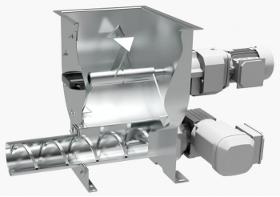

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — except model DSR28 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7088 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Details depend on the characteristics of the medium to be fed (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.) —Applicable feed pumps: piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc. — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy — Heated versions available (electrical, hot water, thermal oil, etc.) Power range - Different Versions 1 - 1000 dm³/h 50 - 5000 dm³/h 100-10000 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— No stirring agitator or other rotating parts for ingredient flow without degradation — Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range Power range 10 - 450 dm³/h 20 - 1000 dm³/h 300 - 3000 dm³/h 650 - 6500 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

* Loss-in-weight FiberXpert feeder for long and uneven fibers (natural fibers, wood fibers, carbon fibers, etc.)* Also suitable for film chips and shredded film strips cut off by film edge trimmers * Technical features: special fiber screw, large steep walled hopper, novel design and special position of the stirring agitator in the hopper * High-tech weighing system with digital load cell or * high-resolution strain gauge load cell for high weighing accuracy Power range 200-19900 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stable dust-tight design for harsh industrial conditions — Removable doors for quick cleaning — Usable as a continuous or batch-wise metering belt feeder or for throughput metering (operating mode can be changed on the controller) Power range 200-50000 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — 3 phase AC gear motors — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-298 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7500 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-2693 dm³/h 20 - 2693 dm³/h

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Large entry pinch rollers driven synchronously with all bottom work rollers Great feeding accuracy of +/ 0,1 mm Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Hard chromed rollers Polyurethane coated rollers Hydraulic cleaning stroke Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Great feeding accuracy of +/ 0,1 mm Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Synchronized drive of all bottom work rollers and both feed rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic full piloting Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

If you need two Coil Reels to hold one coil, you need a Heavy-Duty Coil Feed Line above all. One that is designed extremely robust and knows to subdue even materials of highest bounce and largest cross-sections.To ensure this, we have taken no heed to cost savings but went by the maximum principle: 2 Coil Reels with high-performance arbors retain the coils from left and right. 2 x 2 hydraulic arms secure them from top and bottom – each with eight tons pressure force, each with hydraulically driven snubber roll. The loading is done with one central lifting gear built into a super-duty running frame for the V-nest. Hydraulic manipulators with pivoting and bending function support the threading of the material. On the receiving end, a Pre-Straightener with 200mm work rolls takes over, after hydraulic edge guides have ensured central entry. Now, if someone asks us our definition of “heavy-duty”: We find 36.000 kilogram coil weight and 2.

Request for a quote

GSW SCHWABE AG

Germany

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— RS 485 interface for internal Brabender fieldbus — Application software for DDW (loss-in-weight feeder), DBW (dosing belt scale) or Coriolis flow meters — internal pluggable fieldbus connection — can be controlled via the OP1, OP6 and OP16

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Congrav® CB-E installed in control box or cabinet — Supply voltage: 24VDC — control software for discontinuous dosing of gravimetric dosing devices — Operation on the Brabender fieldbus and master computer — Serial drive controller — Serial load cell — Digital signals — Integrated bus connector Operation: — Congrav® OP16-E — Congrav® OP6-E — Congrav® OP1-S

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Congrav® CB-S installed in control box or cabinet — Supply voltage: 24VDC — control software for discontinuous dosing of gravimetric dosing devices — Operation on the Brabender fieldbus and master computer — Serial drive controller — Serial load cell — Digital signals — Integrated bus connector Operation: — Congrav® OP16-E — Congrav® OP6-E

Request for a quoteResults for

Feeder - Import exportNumber of results

24 ProductsCompany type