- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- granulation

Results for

Granulation - Import export

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

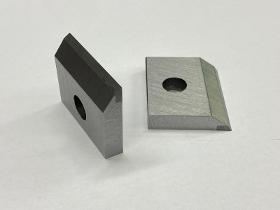

Different tungsten carbide qualities with a hardness above those of the standard and PM special qualities. Through clean grinding materials, we achieve a long working life through high resistance to wear.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Clothing instead of landfill PET must beone of the most interesting recycling materials of recent years as, during this time, not only new bottles, but also clothing and much more have been produced from recycled bottles. In Germany alone, each year the volume of PET bottles discarded when empty has exceeded 400,000 [tonnes], 96% of which is taken to professional recycling. An additional 60,000 tonnes arises annually as packaging material. However, PET is an extremely abrasive material, which exacts enormous demands on the tools used in recycling. Our knives have been proven by their high resistance to wear, and we also supply, in addition to our proven quality standards, extremely hardwearing special qualities.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The high-shear mixer is a system for mixing, granulation of pharmaceutical powders and granulated products. Moreover, it is suitable for a wide range of cosmetics and food products. A three-bladed mixing tool rotates in a vertical, cylindrical mixing vessel close to the wall and to the bottom of the vessel. The shape and peripheral speed of the mixing tool create a vortex-like circulation of the mix. A separately driven chopper is used for breaking up agglomerated products as well as for moistening and granulation. Liquid addition is either gravimetric or uses a pump to add liquid directly to the effective range of the chopper, so that the best possible distribution is ensured. The optional wet sieve on the discharge ensures a completely homogeneous distribution of the granulate size. The PC/PLC-based control system to be compliant with CFR-21 Part 11. The updated user interface permits intuitive machine operation in service and automatic mode for production and cleaning operation.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

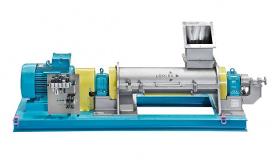

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances. The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The product is moved through the mixing chamber in a plug-flow manner. The retention time is extremely short compared with a continuous ploughshare mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. Liquid components are introduced directly into the product ring layer – either via tangentially placed liquid pipes through the drum wall or via a hollow mixing shaft with specially perforated tools. However, moistening of the mixer wall and shaft is largely prevented. The liquid distribution is similar to a nozzle but avoiding any risk of clogging or disturbance of the spray.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

Lödige has years of expertise in continuous granulation. Nowadays, continuous ringlayer mixers are established systems for continuous granulation in many industries. However, until now the Lödige product range was missing a suitable dryer. The continuous fluid bed dryer closes this gap. Together with the ringlayer mixer CoriMix® and the customer-specific dosing system, this dryer provides a complete continuous granulation line: GRANUCON®. Dryer operation is based on the fluid bed process. A general disadvantage of continuous fluid beds is the wide retention time distribution within the machine. Lödige’s developers have looked into this problem and have found a solution: integrating a screw in the fluid bed dryer. This has a limiting effect on the retention time distribution. — Exchangeable floor — Quick screw removal — Integrated WIP cleaning — Individual purging of filter elements

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Recycling made easy Our machine knives, of uncompromising quality, have been used for decades in recycling for tyre crushing. Even when separating rubber and spring steel, they have been proven in practice day by day. Whether shredder knives, spacers, scrapers or sealing gaskets, shredder teeth for multipleshaft shredders, rotary and stator knives for granulators or machine knives for guillotines Our complete range of products also covers the most demanding challenges in recycling.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Optimum crushing instead of cable salad The very best method for crushing of cables or electrical scrap has brought many a tool to its limits and yet this is a frequently underestimated source of money. In addition to expensive copper, the recycling process also recovers aluminium and noble metals. In order to reach these valuable raw materials, robust preliminary crushing units are used, followed by a second crushing cycle. The demands on the crushing knives cannot be ignored and they must therefore be very tough. We are at the side of our partners to give advice on the selection of ideal materials and the best heat treatment.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® GB Glass granules type are carefully crushed in a special grinding process to give it its predominantly angular cubic shape. In the production of glass granules, soda-lime glass is crushed and sifted according to individual grain sizes. Glass granules are an iron-free, mineral blasting medium.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Plastic is a thermoplastic and belongs to the organic polyamidebased blasting abrasives. WIWOX® KS nature high-quality blasting and deburring medium is particularly suitable to treat duroplast and rubber components without damaging and matting them. Available in cylindrical or exact cubic shape, it is characterised by high impact strength, dimensional stability and extremely long service life. We also supply an antistatic agent for subsequent or sustained application in liquid form.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The granulation dryer is designed for continuous operation. A unique property of this dryer is its combination of convection and contact drying. Adaptation of the retention time to the specific process ensures that products are dried at low temperatures. At the same time, excellent granulation of the final product can be achieved. This intense mixing effect separates the particles in the fluid bed, thereby creating a large product surface and preventing the generation of temperature and moisture gradients in the product bed. This leads to a significant increase in the heat exchange via the heated drum walls. The product behaviour during drying is affected by the mixing tool geometry and choppers can be activated as an option; these can be used to control the average product retention time and the retention time distribution. It is therefore possible to achieve a defined grain size distribution during granulation processes

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

In addition to common applications such as shrink BOPP tobacco films, CONSTAB Modifier masterbatches can also be used for other applications. They provide a whole range of benefits - from labels to transparent food packaging. For example, they contribute to improved mechanical and optical properties, create an increased gas barrier or better processability.

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

CONSTAB offers a wide range of masterbatches with which you can provide your BOPP films with the required or desired properties. There is a wide range of properties with which BOPP films can be provided for individual use. At CONSTAB you will find BOPP masterbatches for co-extruded films, matt films, for metallizable matt films, cigarette film and metallizable films, among others.

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

CONSTAB offers you a wide range of masterbatches and compounds for polyethylene films, such as: — Bubble Film — Electronic packaging film — Injection molding and extrusion blow molding — Foamed films — Food packaging films — Greenhouse films — Film packaging for industry and food — Industrial films — Industrial packaging films Our masterbatches and compounds provide your products with the properties they should later have.

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

CONSTAB and the Kafrit Group offer high-quality and reliable masterbatches and compounds for greenhouse films, mulch films, silage films or for agricultural nets.

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

CONSTAB CON-Xtend 21 is used to produce articles for industrial packaging and food packaging. Improve your barrier packaging with CONSTAB CON-Xtend 21, an innovative solution that allows you to adjust the barrier effect according to your specific requirements. Using CONSTAB CON-Xtend 21 saves EVOH and therefore costs, increases productivity and ensures recyclability without compromising on oxygen barrier.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

With CONSTAB CON-Batch 30X, films can be produced denser and firmer - the layer thickness, on the other hand, can be reduced by approx. 25 %, the heating power by approx. 20 %. CONSTAB CON-Batch 30X masterbatch is used, for example, in the production of thermoformable sheets and enables the overall thickness of the sheet to be reduced by up to 30% while maintaining its mechanical integrity. It improves the mechanical and optical properties of the final product. In addition, the masterbatch serves as a processing aid in extrusion applications, enabling higher production speeds and a wider processing window, while reducing energy consumption. CON-Batch 30X can be easily used in monofilms and thus recycled. CON-Batch 30X can be supplied with a certificate confirming CO₂-neutrality.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

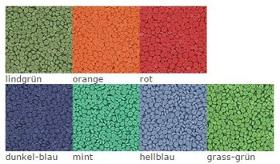

The sliding surfaces used in the past had a number of weak points, which can be attributed to the granules used: Quartz sand is too hard and destroys the base coverings very quickly, while the various rubber granules are too soft and too uneven in shape, so that they in turn are ground up relatively quickly. Both sliding media are controversial due to the dust they generate and bring with them unpleasant side effects such as breathing difficulties, discolouration of clothing and a great deal of cleaning work in the tennis hall and social areas. A new manufacturing process has made significant progress possible: Perfect-Glide tennis granules are not ground from a block of rubber like conventional granules, but are spun into threads using an extruder and then cut to a defined length in a cooling bath. This process enables the production of fine, dust-free extruder micro-granules in a new, optimised lens shape.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Extremely durable materials place extreme demands on the knives with which they are processed. Our knives are customized for a wide variety of material mixtures and therefore perform excellently in cold and hot cutting processes.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Plastic blasting abrasives type WIWOX® KS have been specially developed for optimum, chemically neutral surface treatment and all gentle cleaning – especially for plastic and light metal. They are mainly used for paint stripping, roughening, matting, deburring and cleaning. Plastic blasting abrasives produce consistently high quality and do not cause any damage to the work piece to be treated.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Walnut shell abrasive type WIWOX® WA is a soft granulate and belongs to the organic abrasives. It is produced crushing, washing and sieving the walnut shells. Walnut granules are particularly suitable for the gentle cleaning of delicate surfaces.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Light, spherical, mineral and ferrite-free glass beads blasting abrasive WIWOX® GP. Ideal for bright, matt-gloss surfaces. The area of application ranges from the cleaning of delicate tools to the deburring of precision parts through to the finishing of precious and non-ferrous metals.

Request for a quote

REILING GMBH & CO. KG

Germany

We supply high-quality PET regranulate made from our PET flakes (single-use beverage bottles). Prior to the regrinding process, the bottles are processed into clean and sorted flakes. Our PET regranulate , known for its purity, has various applications and is suitable for food contact due to its decontamination process. We deliver the end products in sturdy BigBags with liners to our customers. With our extensive recycling experience and quality-tested recyclate, we are your reliable partner. Verified Quality: Our PET regrind is manufactured and monitored according to stringent quality standards. Parameters such as bulk density, color values, chemical content (acetaldehyde, benzene, limonene), presence of foreign substances (black specs), and crystallinity are checked. Versatile Applications: PET regranulate offers a wide range of applications and can be used in various types of food packaging and other plastic applications due to its homogeneous form and purity.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for solids from granulates to rocks The OPTIWAVE 6400 is a 2-wire 24 GHz radar (FMCW) level transmitter for basic applications with solids. This radar is designed for continuous, non-contact level measurement of stones, plastic granulates, coffee beans and other products in solids processing of various industries. The level transmitter features a Metallic Horn antenna as well as PP and PTFE Drop antennas. The Drop antenna design minimizes scaling and is unaffected by the angle of repose. Hence no need for expensive antenna aiming kits or purging systems.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec pneumatic conveyor S-WS is used when, for example, local conditions do not allow the use of a spiral conveyor, for example when the minimum radius of a flexible conveyor can not be met or to overcome larger conveyor lines. Here are some features of the pneumatic conveyor: - Suitable for conveying granules and dry powders - Large filter surface - Filter cleaning by means of compressed air - adjustable interval filter cleaning - High throughput - Ideal for long conveyor lines - Fields of application: plastics and food industry as well as chemical and environmental sector. - Different filter sizes up to 10 m2

Request for a quoteResults for

Granulation - Import exportNumber of results

27 ProductsCompany type

Category

- Granules for plastics (7)

- Precious and semiprecious stones and pearls (5)

- Steels and metals - forming and cutting (4)

- Pharmaceutical industry - machinery and equipment (2)

- Chemical industry - machinery and equipment (2)

- Mixers and grinders for the food processing industry (2)

- Plastics - recovery and recycling (1)

- Goods handling systems, continuous (1)

- Knives, industrial (1)

- Measurement - Equipment & Instruments (1)