- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bottling and filling - machinery and equipment

Results for

Bottling and filling - machinery and equipment - Import export

BÜRKLE GMBH

Germany

Disposable funnel for reliable filling of liquids, ideal for filling bottles and other containers with a narrow filler opening. The disposable funnel ensures no loss when transferring liquid samples or free-flowing solids. That makes this practical and hygenic pouring aid a helpful accessory for sampling or in laboratories. Clean room produced funnel with suspension eye and venting fins for ventilation to ensure uniform flow while pouring. The disposable funnel for liquids is ideal for use in laboratories and clean rooms or for sampling. It can be used in pharmaceuticals, chemistry and cosmetics and the food and animal feed industries, as well as all areas where special purity is important.

Request for a quote

BÜRKLE GMBH

Germany

Universal thread adapter for nearly all drums and other containers with opening of 48–75 mm in diameter, regardless of the respective thread. The thread adapter can be mounted quickly and easily with clamping screws and can be used for different container openings. With G2" connector thread for Bürkle drum screw connections and pumps with immersion tube diameter up to 32 mm. The container connectors make decanting even easier and safer with their more secure connection to barrels. The connectors secure the pump in the barrel, enable a vertical position change and allow the required air exchange.

Request for a quote

BÜRKLE GMBH

Germany

The disposable powder funnel has a short, wide discharge and is suitable for transferring powered samples and materials, granulates ans suspension as well as other liquids. The wide opening of the disposable powder funnel prevents the powder or granulates from clogging while dispensing. That makes this practical and hygenic pouring aid a helpful accessory for sampling or in laboratories. In combination with a filter paper the disposable funnel is also well suited for filtering. The sturdy disposable funnel for powdered substances is ideal for use in laboratories and clean rooms or for sampling. It can be used in pharmaceuticals, chemistry and cosmetics and the food and animal feed industries, as well as all areas where special purity is important.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTec dosing and filling pump RD-Hygiene for food and cosmetics is a volumetric pump based on the continuous piston principle. It is ideally suited for discontinuous or continuous pulsation-free dosing of viscous, structure-sensitive and solids-laden media. Thanks to the high-quality ViscoTec dispensers, high-precision dosing applications can be realized in the food and cosmetics sector. The systems are used e.g. in the bakery and confectionery sector for decoration. Typical doses are icing or fondant, but also fillings such as vanilla or chocolate cream. Your advantages: - Specially adapted filling tubes for a wide variety of filling applications - Application and dosing in automated systems - Low to high viscosity as well as abrasive, shear-sensitive or lumpy media - hot and cold filling - Optimum results for CIP/SIP (Cleaning in Place/Sterilisation in Place) cleaning

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container.

Request for a quote

BIZERBA SE & CO. KG

Germany

This semi-automatic, flexible all-round filling system FSL-PRO S ensures your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. This compact unit is ideally suitable for minimal space. The professional, safe filling of various liquids is an important processing step for many companies. Also particularly difficult to process products are reliably filled and weighed in different containers. Besides this flexibility you benefit from reduced downtimes. You can change products and units quickly and easily.

Request for a quote

BIZERBA SE & CO. KG

Germany

Filling system FSL-ECO S is the optimal entry level model for small companies who want to fill high-quality, uncritical and non-flammable liquids. With automatic filling as accurate as 1 gram this practical system lets you save time and money. FSL-ECO S offers particular advantages for companies where filling of liquid products is a firm part but not the main task in their production process. This system is the first step from manual to automatic filling. The semi-automatic system safely and reliably fills all common containers such as canisters, pails, drums or IBCs. Products are handled manually and the automatic filling provides to-the-gram results. You avoid over or underfilling and save valuable time.

Request for a quote

BIZERBA SE & CO. KG

Germany

The fully automatic filling system optimizes your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. By means of a multifunctional offset slide you benefit from maximum flexibility for container types and sizes as well as from efficient handling without retrofitting time. The fully automatic machine FSL-EVO S facilitates quick and reliable filling of high quality and sensitive products in different containers. Products can be fully automatically closed and labeled with variable data, if desired. By means of a set up buffer section the filling system largely works autonomously.

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container. Less over and under fillings. When used with a dual scale, the filling process is considerably accelerated while working with the same precision and quality: In parallel, you can fill and weigh on one scale and close and further transport...

Request for a quote

BIZERBA SE & CO. KG

Germany

This semi-automatic, flexible all-round filling system FSL-PRO S ensures your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. This compact unit is ideally suitable for minimal space. The professional, safe filling of various liquids is an important processing step for many companies. Also particularly difficult to process products are reliably filled and weighed in different containers. Besides this flexibility you benefit from reduced downtimes. You can change products and units quickly and easily. The FSL-PRO S is also available as an Ex model for zones 1 and 2. Same as with all our Ex models it meets ATEX guidelines. No need to remove the filling valve for efficient and thorough cleaning of the system. You save work steps and time. Ideal for frequent product changes. The filling system can be easily run by an operator and allows parallel working: Optional expansions let you perform capping and...

Request for a quote

BIZERBA SE & CO. KG

Germany

Filling system FSL-ECO S is the optimal entry level model for small companies who want to fill high-quality, uncritical and non-flammable liquids. With automatic filling as accurate as 1 gram this practical system lets you save time and money. FSL-ECO S offers particular advantages for companies where filling of liquid products is a firm part but not the main task in their production process. This system is the first step from manual to automatic filling. The semi-automatic system safely and reliably fills all common containers such as canisters, pails, drums or IBCs. Products are handled manually and the automatic filling provides to-the-gram results. You avoid over or underfilling and save valuable time. The various manual closing systems prevent the containers from leaking. FSL-ECO S ensures smooth processes. Our options allow you to expand your system individually and adjust it to your requirements. Interchangeable filling valves, for example, ensure a hygienically perfect...

Request for a quote

BIZERBA SE & CO. KG

Germany

The fully automatic filling system optimizes your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. By means of a multifunctional offset slide you benefit from maximum flexibility for container types and sizes as well as from efficient handling without retrofitting time. The fully automatic machine FSL-EVO S facilitates quick and reliable filling of high quality and sensitive products in different containers. Products can be fully automatically closed and labeled with variable data, if desired. By means of a set up buffer section the filling system largely works autonomously. Your advantage: Possible operating errors resulting from incorrect settings can be minimized. The FSL-EVO S is also available as an Ex model for zones 1 and 2. Same as with all our Ex models it meets ATEX guidelines.

Request for a quote

LIQUID-UNIVERSUM GMBH

Germany

filling machines for liquids 550ml and 1001000ml (cbd oil, e liquid, desinfection, cosmetics, nutritions, vitamins)

Request for a quote

WHITE STEEL GMBH

Germany

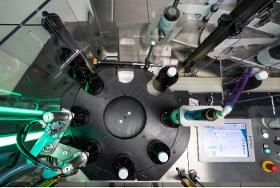

DESCRIPTION: High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Volumetric filling system SCADA and HMI with a touch screen system 2 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system UV sterilizer system Servo conveyor system Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITESTEEL GMBH

Germany

- Compact design - Made up to the ISO, FDA and EU, GMP and cGMP international standards - Can handle multiple cups shapes and sizes - SCADA system included - Touch screen included - Capacity is adjustable up to your needs - Can be used For all liquid substance including alcohol, sanitizers, hand gel, and more

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Bottling and filling - machinery and equipment - Import exportNumber of results

17 ProductsCountries

Company type