- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gears

Results for

Gears - Import export

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The Vertical Rotary Table Grinder Model TRIREX is a modular designed machine. The Vertical Rotary Table Grinder has a bigger vertical stroke, which allow the machine to process the required working envelope. The Vertical Rotary Table Grinder consists of well proved modules. A long-term experience in the field of grinding with special machines guarantees the actual grinding technology. Important points include : Control (Siemens or Fanuc) Up to 5 axes CNC grinding center Optional with turning and measuring option High preassure deburring Up to 4 spindles possible Grinding capacities from 7,5 - 60 kW Dressing spindle next to the rotary table Tool changer Work piece Loading Zero point clamping system

Request for a quote

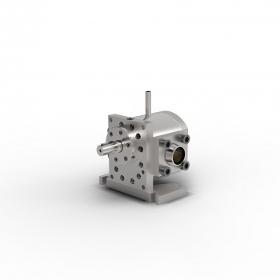

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The POLY-AT design offers exceptional flexibility when it comes to installations beneath the polymer melting reactor. Customers can choose from three different flange geometries to ensure they are always benefiting from the best combination of reactors and pump flanges from both a technical and economical perspective. The new gear geometries facilitate differential pressures of up to 320 bar for selected pump sizes. What’s more, the new design is rounded out with the usual variety of different material combinations. The most common of these combinations has to be a stainless-steel or carbon-steel housing with tool steel or aluminium-bronze friction bearings.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Witte chemical pumps are used as dosing pumps for a variety of fluids. Pumps of the CHEM series are designed and assembled exclusively at the Tornesch site, thus guaranteeing highest reliability and quality. For all our series we offer a comprehensive spare parts service on request. In addition, we also install the pumps directly at our customer's plant. Dosing pumps of the CHEM series are extremely flexible in their design and can be offered in various variants and equipment thanks to a modular system. Differential pressures up to 120 bar, suction pressures vacuum up to 15 bar Temperatures up to max 500 °C in combination with a magnetic coupling. Viscosities up to 1.000.000 mPas or higher Components made of stainless steel, ceramic and special materials Flow rates from 20 l/h to 170,000 l/h

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

We bring our success, our wealth of experience and our know-how to the chemical industry. The requirement to pump viscous and sticky substances out of a vacuum is no easy task. However, our CHEM design easily meets this requirement. The requirements for dosing and transfer pumps as well as for distillate pumps in the CBD segment, for example, also match our CHEM design so that you get a pump solution for your entire distillation process with just one pump. More than 600 pumps of this design are running reliably in a wide range of cannabis applications at a number of our US customers. This robust and reliable pump series is used worldwide in demanding processes in the chemical and pharmaceutical industries.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of HDPE / LDPE / LLDPE. Melt pumps of this type are used in the production and processing of HDPE / LDPE / LLDPE. The EXTRU series is exkat adapted to the requirements in these processes and thus works with highest precision. Special serrations allow an almost pulsation-free conveyance of the melt, which guarantees a constantly high product quality.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Gear pumps with magnetic coupling The magnetic coupling is equal to contact-free drive and seal. Magnetic coupling pumps are used if critical media has to be transported. The seal ensures that the pumps work 100% securely and without leaking. The magnetic coupling is particularly ideal for hazardous substances that should not escape into the enviroment. The coupling is hermetically sealed and can be designed with different sensors for monitoring and in different variations and materials. A magnetic coupling is used in combination with a chemical pump by default.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of medical flow. Melt pumps of this type are used, among other things, in the production of medical fluids, such as those used in respiratory masks. The melt-blown fluid can be used in many different ways in protective masks or filters. The EXTRU series is exkat adapted to the requirements of the melt-blow process and thus works with highest precision.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

EXTRU - Melt pump for extrusion and pressure increase of medium to high viscosity media. The extrusion gear pump is mainly used in combination with extruders or kneaders. It reduces the natural pulsation of the extruder and compensates for fluctuations in delivery, especially in single screw extruders. The extrusion pump is used as a melt pump. It builds up the required feed pressure, which is needed for the downstream die. The pressure build-up in the gear pump can be much more efficient than in the extruder itself. The extruder is relieved by using an extrusion pump. Furthermore, considerably less energy or heat is introduced into the polymer. The melt pump thus contributes to conveying the product as gently as possible. The EXTRU is indispensable for the production of precise films or micro pellets.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Stainless steel metering gear pump for the delivery of chemical raw materials for the production of pharmaceutical products. CHEM metering pumps are also used to pump isocyanate, sulphuric acid, polyol or essential oils. With the appropriate combination of materials, many critical applications can be realized and a variety of low-viscosity fluids can be pumped. The range of applications extends from classic transfer and metering tasks in the chemical and pharmaceutical industry to the pumping of monomers, oligomers and prepolymers in polymer production. These chemical pumps are suitable for even the most difficult tasks and impress with their reliability and dosing accuracy in both vacuum and high-pressure applications. Typical applications for this pump type are in the chemical, cosmetics, food, petrochemical and polymer industries

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The CHEM gear pump series was developed especially for the requirements of the chemical industry. The series is used for pumping and transferring low to medium viscosity media. The CHEM series is extremely flexible in its design and areas of application. Technical details: — Suction pressures from vacuum up to 15 bar and suction pressures with magnetic coupling up to 25 bar — Delivery volume 1.28 cc/rev to 12,000 cc/rev — Temperatures up to 300 degrees — As special pumps for the chemical industry according to customer specifications — Viscosities up to 1.000.000 mPas

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pump hydraulically temperature controlled for a wide range of applications. This ranges from organic and inorganic chemicals to food oils, polymers and pharmaceutical products. A wide-ranging modular system provides optimum material combinations for corrosive or abrasive media.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pump with electrical temperature control. The CHEM series is designed to be easy to maintain. Separate pump covers allow a quick inspection of the inner workings from both sides of the pump. To adjust the axial clearance we use shims which can be varied according to process parameters. Chemical pumps of the CHEM series are offered as standard versions with components made of stainless steel or as special versions with coated or ceramic materials. To bring or maintain the pump at process temperature, two temperature control variants can be used, electric and hydraulic.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump specially designed for use in the production of medical tubing made of TPE, PE or PA. The melt pump is installed downstream of the extruder in the extrusion process for pressure build-up and constant delivery of the melt to the die. It is particularly important for medical tubing that the wall thickness and quality is absolutely constant and uniform.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Carbideline consists of CarbideLine-S solid carbide tools, CarbideLine-H hybrid tools and multi-part carbide tooling with CarbideLine-I indexable carbide tools. All CarbideLine tools excel through maximum productivity in their specific fields of application. CarbideLine-H tools are a new addition to the product range. They cover the module range 5 to 12 and are the 1st. choice for rough machining and finishing large lot sizes, where the tools costs using solid carbide milling cutters are too high and the gear cutting quality is too low using indexable inserts. CarbideLine-H tools are also highly suitable for machining high-strength materials up to 1,400 N/mm2 and enable a gear quality up to quality grade AAA. Its preferred area of application is for gears for commercial vehicles, general mechanical engineering and energy technology. In one specific application it was possible to reduce the gearing costs per wheel by 20% with the CarbideLine-H compared with an indexable insert system.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

SpeedCore is a newly developed substrate for hobs. The increased hot hardness of the intermetallic cutting material allows for cutting speeds of at least 30 % higher compared with HSSPM4/ 14 hobs, resulting in shorter production times without sacrificing tool live and ocmplies with the demand of customers for easy handling and easier recycling. Combining the new SpeedCore substrate with a custom coating achieves top performance with easy implementation and high reliability. Advantages - Improved productivity of up to 70 % - Process reliability (like HSS-PM) - Easy to implement; also on older or unstable machines - Regrinding and coating possible without problems

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Gears - Import exportNumber of results

17 ProductsCountries

Company type

Category