- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- loading unloading

Results for

Loading unloading - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Lödige Industries has developed a ULD loading station designed to increase safety and efficiency levels while loading baggage into ULD containers. The design has been used at major airports like London Heathrow to facilitate and speed up baggage ULD loading and unloading. This inhouse Lödige product ensures the safe and effective handling of ULD’s during the transfer process on the apron. Ball units give a smooth and light transfer from/to the dollies, whilst the addition of pneumatically driven pads and stop pins ensure the ULD is safely held in position for loading and unloading. Benefits: Supports peak flow efficiently and reliably Reduces stress and injury at the workplace

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Lifting height up to 1,800 mm Load capacity up to 6000 kg The lifting tables in the Middle Class are available in any preferred size. Thanks to the modular design (base frame, scissor arms, hydraulic unit, platform sizes and options) they can be easily adapted to individual needs, taking into consideration also characteristics of loading/unloading areas. Benefits Infinitely variable hydraulic height adjustment Extensive project know-how Production according to German quality standards

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Dolly Docks from Lödige facilitate the airside loading and unloading of air cargo units Dolly docks receive and send off ULDs on airside. Fast and smooth transfer is essential. Our dolly docks can be equipped with a hydraulic tilting function and can form part of an airlock. Sized and equipped to your requirements, the dolly docks from Lödige will facilitate your airside interface.

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

HEAVYDRIVE GMBH

Germany

The glass lifting device is an innovative solution for unloading, loading, transport, and fitting glass. One person can transport a glass panel weighing 80 kg. The device can be easily assembled and disassembled – it only weighs 35 kg. It has large 13 inch wheels which allow it to move on uneven surfaces. The wheelbase can be adjusted, which enables it to pass through doors and move on narrow pavements.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The "Main-Deck" Laders 14 and 30 t are specifically designed for the clearance of wide-body aircraft and have long been one of the preferred solutions for nose-loading the Boeing 747 and for loading and unloading the main cargo deck of the Airbus A 380.

Request for a quote

GMÖHLING TRANSPORTGERÄTE GMBH

Germany

Container trolleys of aluminium with smooth surface Reinforcement rims at top and bottom provide load stability With slide-down side for easy loading and unloading Antistatic and do not attract dust or dirt With full- rubber tyres, non-marking and thread protection 2 swivelling castors with brakes in accordance with European standard DIN EN 1757-3 Transport trolley D 3708 - Models

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The predominant use of LAWECO lifting platforms in the paper industry is for the formation and separation of stacks. Additional application possibilities are the handling of paper rolls and rack loading. Lifting table to load and unload storage carts for printing cylinders incl. control station for operator. Dimension: 5350 x 2500 mm Operating stroke: 2850 mmm Rated load: 2500 kg

Request for a quote

SCHOLPP GMBH

Germany

Agility meets efficiency. Anywhere, any way. When we transport and relocate machinery, we move parts of all sizes. Whether we’re moving with heavy goods vehicles or by rail, plane or ship, our experts know which is the fastest, most cost-efficient and best way, and make sure everything arrives smoothly at your destination. Regardless of the mode of transport you need for your relocation, SCHOLPP can coordinate every element of the logistics, planning and monitoring. The SCHOLPP project team will also take care of all the necessary customs procedures. The loading, unloading and temporary storage of your goods is all in good, professional hands. SCHOLPP gets your equipment to its destination by any form of transport – road, rail, air or water.

Request for a quote

GMÖHLING TRANSPORTGERÄTE GMBH

Germany

Container of aluminium with smooth surface Cut side wall approx. 1130 x 250 mm facilitates loading and unloading Reinforcement rims at top and bottom provide load stability Antistatic and do not attract dust or dirt With full- rubber tyres, non-marking and thread protection 2 swivelling castors with brakes in accordance with European standard DIN EN 1757-3 Transport trolley D 3808 - Models

Request for a quote

GMÖHLING TRANSPORTGERÄTE GMBH

Germany

Gmöhling’s versatile transport trolleys are available in different sizes and versions. Standard versions include trolleys with smooth, ribbed, perforated and anodised sides. An essential feature of our transport trolleys is the cut-out/hinged or sliding panel on one side for ease of loading and unloading. Our light and robust transport trolleys have multiple uses for storage and transport in your logistics. They have proved themselves over the years in many sectors such as industry, the automotive, disposal and pharmaceutical industries and the hospital, laundry and catering sectors, etc. We offer various wheel systems according to load weight to guarantee easier handling. We can also supply transport trolleys with an appropriate hinged lid to your required size. Containers of aluminium with smooth surface With reinforcement rims at top and bottom for load stability With fold-down side for easy loading and unloading Antistatic and do not attract dust or dirt With full- rubber...

Request for a quote

MT CONTAINER GMBH

Germany

Take full advantage of our open side containers! The openings on the longitudinal sides make the loading and unloading process much easier. In addition, there are numerous possibilities for alternative applications in the realm of events and exhibitions. The expertise of MT Container GmbH helps you find the right open side container for purchase or rent in an uncomplicated and timely manner. What Can Open Side Door Containers Do For You? An open side container also known as side door container is a variant a of standardarized container that can be opened along its longitudinal sides. They have multi-wing openings on the side wall, allowing variable openings of the desired sections. Thanks to the side openings, loading and unloading is particularly comfortable with respect to sea containers, which only have double doors at the front. Due to the large opening, it is also possible to move rather bulky objects that do not fit through the doors of standard units. So, an open side...

Request for a quote

SAMSYS GMBH

Germany

The mobile robot ER Work from EasyRobotics is a compact robot station which can be used for handling work or CNC assembly. The ER Work is most often used in combination with the ProFeeder Compact. Here the ProFeeder Compact serves as a kind of parts store. In this case the ER Work loads and unloads the machine. Of course, the ER Work can also do its work alone in front of a CNC machine.

Request for a quote

KAUP GMBH & CO KG

Germany

Using KAUP Telescopic Forks trucks, wagons and goods stored double deep on shelves can be loaded and unloaded. To achieve this, Telescopic Forks are designed with hydraulic synchronous fork shoes which can, if necessary, be extended step-less.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

PENDULUM CHANGER – GOOD FROM EXPERIENCE. The W-axis principle, established by SAMAG since 1995, enables workpiece loading to be carried out parallel to production times. The workpiece carrier table is moved in the swivel drive from 0 – 180°. This means that the next loading and unloading of workpieces can take place during processing. Efficient and useful also for robot-assisted loading.

Request for a quote

EUROLASER GMBH

Germany

An increase in productivity thanks to loading and unloading during the cutting process Workpiece removal during the cutting process at the collecting table possible The material feed is stretching-free Accurate placement of the workpiece through automatic edge control with the Feeding Unit Optional camera recognition system for automated processing Optional marking systems (e. g. Ink Marker) Processing of very large formats by edgeless continuation of cuts possible.

Request for a quote

GEDA GMBH

Germany

The personnel and material hoist GEDA Multilift P12 P is an alternative to the classical service- and industrial hoists. It is designed to meet the requirements of the industry. Using the GEDA Multilift P12 P with its single mast, you can transport a maximum of 12 people or 1500 kg. The main features of this hoist are: — enclosed car — completely closed base enclosure — control can be carried out from all loading/ unloading points, from the car and from the base enclosure. A level pre-selection control can be installed as an accessory which enables automatic drive to landing levels.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

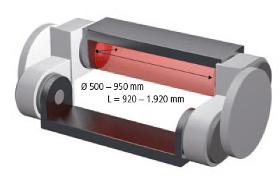

METZNER MASCHINENBAU GMBH

Germany

Metzner provides a number of proven automation solutions for the automatic loading and unloading of coating carriers for CVD and PVD coatings. The abbreviations PVD (Physical Vapour Deposition) and CVD (Chemical Vapour Deposition) stand for different coating processes. When loading the PVD spears, we differentiate between "single-loading" and "back-to-back loading". In addition to part loading, spacers are loaded onto the spears in addition to the parts. In single-loading, a spacer is located behind each individual insert, whereas in back-to-back-loading, two inserts are placed "back to back" and only then is a spacer loaded. To implement "back-to-back-loading", a turning station is integrated into the machinery. This station is used to turn the corresponding insert by 180 degrees, loading it directly onto the respective spear.

Request for a quote

STARRAG GMBH

Germany

In the aviation industry, there is an increasing trend towards larger and larger monolithic structural components. The ECOSPEED series, featuring a horizontal spindle and a vertical pallet arrangement, has been specially developed for highspeed machining of these large structural aluminum components. A pallet transport system feeds pallets to the machine, the storage station and the loading/unloading station. The innovative Sprint Z3 parallel kinematic machining head, provides the user with the optimum 5axis simultaneous machining process. At a maximum cutting volume of up to 8,000 cm3/min, the machine concept is the world's most productive solution for cutting aluminium structural components, drastically cutting both production times and costs.

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

The modular Waferhandling-System facilitates all possible handling processes of wafers. Loading and unloading, conveying, gripping, inspecting, sorting and singulating can be realized in one system. Our Ultrasonic Suspension Technology keeps the wafer on distance the whole time and therefore prevents micro-scratches and contamination. Features of the Modular Waferhandling-System: - Modular Design - Contactless transport - Customizable according to customer specifcations - Linking various processes in one system

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Support winch for semi-trailers Support winch for semi-trailers. Prevents tilting of the trailer during loading and unloading. Load-lifting, capacity 15 t

Request for a quote

H. TIMM ELEKTRONIK GMBH

Germany

The danger of electrostatic charges must always be observed when loading, unloading or handling bulk solids or inflammable liquids in the petrochemical, chemical, gas, as well as in the food and feed industry. For application with containers, IBCs, barrels or trays, the EKX-4 (2-pole) is the Grounding Control Device to choose. APPLICATION AREAS: EKX-4 (2-pole) is mounted stationary, close to the loading/unloading gantry. It is used in gas and dust hazardous areas of zone 1 and 21 for objects to be grounded, that cannot be detected by the standard 1-pole Grounding Control Device EKX-4 such as containers, IBCs or barrels. Further areas of application are the grounding of materials handled with trays on conveyors in automated industrial processes.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Mobile Loader is designed specifically for use in premises without a raised loading dock, which makes it ideal for loading vans and other smaller vehicles. Using this unit makes your vehicle loading/unloading operation faster, safer and more efficient, and helps you comply with manual handling regulations. Construction Heavyduty construction and supporting framework make Mobile Loaders one of the most robust units of its type on the market. Shrouded Buttons To limit the damage to emergency stops, FMH Conveyors add fabricated steel shrouds to the exposed emergency stop buttons. Fully Guarded All moving or rotating parts are fully guarded to prevent entrapment and injury. Mobile Mobile Loader units are fully mobile utilising 200mm heavy duty castors.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction BestReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

H. TIMM ELEKTRONIK GMBH

Germany

- For use during loading and unloading of tank trucks, silo trucks and rail tank cars - Controlled derivation of the static electricity - Use in gas and dust hazardous areas of zone 1 (equipment category II 2 G) and 21 (II 2 D) - Immediate interruption of the loading operation when unsafe grounding connection consists - EAC Ex approval according to the currently relevant TR-CU 012/2011 regulation

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The MaxxReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction MaxxReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

The functional bag features a large, full-length zipper that allows for clean and convenient loading and unloading.

Request for a quote

SMITO-TECHNIC GMBH

Germany

Lifting aid with smooth hoist to lower / raise the racks (sieve basket, hooks, wire mesh crates, or similar) holding the workpieces into / out of the tank. This facilitates loading and unloading at a comfortable height, and without any direct contact with the chemicals.

Request for a quote

SMITO-TECHNIC GMBH

Germany

Lifting aid with smooth hoist to lower / raise the racks (sieve basket, hooks, wire mesh crates, or similar) holding the workpieces into / out of the tank. This facilitates loading and unloading at a comfortable height, and without any direct contact with the chemicals.

Request for a quoteResults for

Loading unloading - Import exportNumber of results

32 ProductsCountries

- Germany (32)

- Bonn, Düsseldorf and North Rhine and Westphalia (9)

- Frankfurt am Main and Hesse (2)

- Hamburg and region (2)

- Hannover and Lower Saxony (1)

- Kiel and Schleswig-Holstein (2)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (2)

- Munich, Nuremberg and Bavaria (9)

- Stuttgart, Freiburg and Baden-Wurtemberg (3)

- Weimar and Thuringia (1)

Category

- Conveyor systems (3)

- Mechanical engineering - custom work (2)

- Explosion-proof - equipment (2)

- Hoists and elevators, construction (2)

- Laser - cutting and welding machines (1)

- Handling - Machines & Equipment (1)

- Forklift trucks (1)

- Industrial Vehicles (1)

- Internal transport systems (1)

- Lorries, vans and commercial vehicles (1)

- Machine tools, metal machining - parts and accessories (1)

- Robotics (1)

- Shearing machine tools (1)

- Warehouse logistics (1)