- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- melting

Results for

Melting - Import export

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of medical flow. Melt pumps of this type are used, among other things, in the production of medical fluids, such as those used in respiratory masks. The melt-blown fluid can be used in many different ways in protective masks or filters. The EXTRU series is exkat adapted to the requirements of the melt-blow process and thus works with highest precision.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

EXTRU - Melt pump for extrusion and pressure increase of medium to high viscosity media. The extrusion gear pump is mainly used in combination with extruders or kneaders. It reduces the natural pulsation of the extruder and compensates for fluctuations in delivery, especially in single screw extruders. The extrusion pump is used as a melt pump. It builds up the required feed pressure, which is needed for the downstream die. The pressure build-up in the gear pump can be much more efficient than in the extruder itself. The extruder is relieved by using an extrusion pump. Furthermore, considerably less energy or heat is introduced into the polymer. The melt pump thus contributes to conveying the product as gently as possible. The EXTRU is indispensable for the production of precise films or micro pellets.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of HDPE / LDPE / LLDPE. Melt pumps of this type are used in the production and processing of HDPE / LDPE / LLDPE. The EXTRU series is exkat adapted to the requirements in these processes and thus works with highest precision. Special serrations allow an almost pulsation-free conveyance of the melt, which guarantees a constantly high product quality.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The POLY-AT design offers exceptional flexibility when it comes to installations beneath the polymer melting reactor. Customers can choose from three different flange geometries to ensure they are always benefiting from the best combination of reactors and pump flanges from both a technical and economical perspective. The new gear geometries facilitate differential pressures of up to 320 bar for selected pump sizes. What’s more, the new design is rounded out with the usual variety of different material combinations. The most common of these combinations has to be a stainless-steel or carbon-steel housing with tool steel or aluminium-bronze friction bearings.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Nominal rated filter cartridges melt blown Type: NT Thermally bonded microfibers made of pure polypropylene Free of wetting agents Depth-filters for the filtration of drinking water, galvanic baths, chemicals, cooling lubricants and emulsions. Complies with FDA regulations

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of plain and rolling bearings at high temperatures and high loads, e.g. on hot-air fans, converters, pouring ladles, sintering systems, conveyor systems subject to heat etc. Advantages and benefits Excellently suited for reducing friction and wear, protection against corrosion and impurities Maintenance of lubricating effect even at high temperatures and loads Highly effective due to selected combination of active ingredients for good corrosion protection properties, good resistance to ageing and excellent EP properties

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

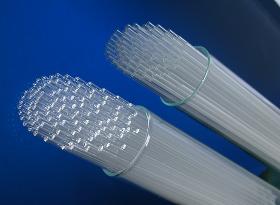

Reliable performance in the most challenging environments Engineered for absolute fiber purity and consistency, POREX® melt blown filter cartridges provide optimized dirt-holding capacity, low-pressure drop, high filtration efficiency, and long lifespans. Entirely made of melt blown nylon microfibers, our melt blown filter cartridges are binder-free and thermally treated for reliable performance in the most challenging environments. Specifically designed for drinking water applications, our melt blown filter cartridges: Increase efficiency–Cartridges are engineered for optimal dirt-holding capacity and high filtration efficiency. Provide chemical and thermal resistance–Nylon structure provides exceptional chemical and thermal resistance. request sample ask an engineer

Request for a quote

MICRO-EPSILON

Germany

The systems of the FTS familiy offer thickness measurements with extreme stability and accuracy. Applying them in extrusion lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Request for a quote

DEKORTECH GMBH

Germany

Strong, water-based adhesive disperion for heat transfers. ✔ For many materials ✔ Different application temperature ✔ Low Viscosity ✔ Great price ✔ Clear coating Our water-based adhesive dispersions are made for heat transfer printing. With different base materials from PU to acrylics, we can create the right adhesive for your applications. Our main products are the MT-I adhesive, which adheres to many materials at temperatures from 50 - 100°C with great hot tack. The second is PPT-I, which adheres to untreated polypropylene at low temperatures. The main use if in combination with toner-based prints, but they can be used with other prints as well. Once we know the application, we can help you find the right adhesive for it!

Request for a quote

DEKORTECH GMBH

Germany

Strong, water-based adhesive disperion for heat transfers. ✔ Flexible film ✔ Hydrophobic ✔ Low Viscosity ✔ Great price ✔ Clear coating ✔ Application temp.: 80 - 100°C ✔ All-purpose adhesie Our V-6 hot melt dispersions is tailored for heat transfer printing. With a medium activation temperatur it can be used also on lots of different materials. The adhesive forms very flexible film that make it a good partner to be used on flexible materials. It can be used well with toner-based prints. The formulations creates good adhesion on many materials, which makes it an all-rounder. It shows good overall resistance without any mayor strength or weakness. Furthermore, the particles in this dispersion are fine dispersed and result in even and repeatable results.

Request for a quote

DEKORTECH GMBH

Germany

Strong, water-based adhesive disperion for heat transfers. ✔ Flexible film ✔ Hydrophobic ✔ Low Viscosity ✔ Great price ✔ Clear coating ✔ Strong hot-tack ✔ Application temp.: 50 - 100°C ✔ For ABS, SAN, PET and more Our MT-I hot melt dispersions is tailored for heat transfer printing. With a wide activation temperatur range it can be used also on materials like PET. Futhermore, the formulation creates and adhesive film which has a high hot tack. Due to this it is easier to achieve great bonds and to print at higher speeds. It shows good adhesion on many materials, which makes it a great adhesive to skip cleaning the coating equipment. It can be used well with toner-based prints. This adhesive is great for heat transfer printing onto cosmetic packaging as well as promotional like pens. It shows good resistance against water. Furthermore, the particles in this dispersion are fine dispersed and result in even and repeatable results.

Request for a quote

DEKORTECH GMBH

Germany

Strong, water-based adhesive disperion for heat transfers. ✔ Very hard once dried ✔ Hydrophobic ✔ Low Viscosity ✔ Great price ✔ Clear coating ✔ Application temp.: 80 - 110°C ✔ For glas, ceramics, ABS, ... Our GK-I hot melt dispersions is tailored for heat transfer printing. With a rather high activation temperatur is results is very durable bonds once applied. It can be used well with toner-based prints. This adhesive is great for heat transfer printing onto glas or ceramic products like wine or spirits bottles as well as promotional or cosmetic products made from ABS. Furthermore, it offers self-crosslinking capabilities which increase the adhesion even further. It shows great resistance against water and heat. The particles in this dispersion are fine dispersed and result in even and repeatable results.

Request for a quote

DEKORTECH GMBH

Germany

Strong, water-based adhesive disperion for heat transfers. ✔ Flexible film ✔ Hydrophobic ✔ Low Viscosity ✔ Great price ✔ Clear coating ✔ Application temp.: 50 - 80°C ✔ For untreated PP (polypropylene) plastics and PET Our PPT-I hot melt dispersions is tailored for heat transfer printing. The formulation is tailored for untreated PP plastics. It also provides a low activation temperatur and a good hot-tack. Due to this it is easy to achieve great bonds on this difficult material, even at higher speeds. It can be used well with toner-based prints. This adhesive is great for heat transfer printing onto cosmetic packaging as well as promotional and industrial products made of PP. It shows good resistance against water, alcohols and cremes. Furthermore, the particles in this dispersion are fine dispersed and result in even and repeatable results.

Request for a quote

BÜHNEN GMBH & CO. KG

Germany

The NS30 hot melt hoses serve as a heated and flexible transport route for hot-melt adhesive, from a melter to a bead application head. The hoses are available in different lengths and nominal widths (=diameter of the hose inner core). Should you not find the length you require here, please contact us. Standard: PT100 or FeCuNi sensor, nominal width NW08 and NW13, High-Flex version Optional: Spray version

Request for a quote

BÜHNEN GMBH & CO. KG

Germany

Pull-off forces reduced by 30% for fatigue-free working Microprocessor controlled, continuously adjustable temperature control +/- 1 °C Digital status display integrated in handle Temperature locking Stroke limiter allows exactly the same quantity of glue to be applied repeatedly (distance of trigger to grip can be adjusted to fit to all hand sizes) Very high dispensing capacity Removable nozzle (standard diameter 3.0 mm) Available in case Removable stands Fixture for use of a balancer

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BÜHNEN GMBH & CO. KG

Germany

The hot-melt adhesive has its applications in industry, floristry, household and hobby. Standard floristic glue Wide open-time window Easy assembly bonding Colour: white-transparent

Request for a quote

BÜHNEN GMBH & CO. KG

Germany

White bio-based hot-melt adhesive for industrial applications in the packaging industry, e.g. coated cardboard and fast carton erectors. Proportion of biogenic carbon: 41% High absorption of restoring forces Good adhesive spectrum Excellent oxidation stability

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump specially designed for use in the production of medical tubing made of TPE, PE or PA. The melt pump is installed downstream of the extruder in the extrusion process for pressure build-up and constant delivery of the melt to the die. It is particularly important for medical tubing that the wall thickness and quality is absolutely constant and uniform.

Request for a quote

HILGENBERG GMBH

Germany

We offer a wide range of tubes for the automatic or manual determination of the melting or boiling points of liquids and solids. For this, the samples are heated slowly in the test tube until they reach their melting or boiling point. Depending on the application and the temperature range, we use the following types of glass for our melting and boiling point tubes: Soda glass (standard) Borosilicate glass Quartz glass Optional end shapes: open at both ends one end closed both ends closed curved Dimensions: Length 50-300 mm Outer diameter 0,6-2 mm Inner diameter 0,3-1,6 mm U-tubes for determining the melting point Apart from the standard melting point tubes, we also manufacture special U-shaped tubes of soda glass. Hereby, the two legs of the U-tube have different lengths. As an additional option, the U-tubes can be fitted with a small funnel on one or both legs. Melting-& boiling point determination tubes

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The basic version of the ZwickRoell Mflow extrusion plastometers can be used to establish the melt mass flow rate (MFR). The plastometer’s modular design is expandable using the piston transducer to permit determination of the melt volume flow rate (MVR) as well as for automatic adaptive parameter configuration. Common uses occur in goods inwards checks and quality assurance. Mflow extrusion plastometer includes the Zwick's automatic adaptive parameter configuration, which sets test parameters based on the material being tested to automatically minimize measuring errors. The basic version of the Mflow extrusion plastometer is designed to perform MFR tests in accordance with Method A and can be expanded for MVR tests as per Method B. Tests to the following standards are possible: Methods A and B as per ISO 1133, ASTM D1238, ASTM D3364, JIS K 7210.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

VSG systems offer a poven and economic solution for the inductive melting of metals or alloys under vacuum or protective gas atmosphere and subsequent casting. Applications: The VSG furnaces can be universally employed for melting and casting under high vacuum or different gas atmospheres in the laboratory or production, e.g. alloying, degassing, purification melting, re-melting processing of noble metals highly pure, highly alloyed steel. • Processing of: ◦noble metals ◦ processing of highly pure, highly alloyed steel ◦ High temperature resistant materials on Fe- Ni- Co- basis ◦ Solar-silicon and other special material ◦ Special- / super alloys

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. Pipe element with flare for melting water line

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The RSF genius provides unparalleled possibilities in regard to attainable product quality, economic competence, operator and maintenance-free operation. This fully-automated and constant pressure filtration system can be utilized in almost any function, for automation of the manufacture process and for the production of a high quality final product. It is also suitable for very fine filtration, filtration of thermally-sensitive melts and filtration of materials with a high level of contamination.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The SF Filtration System is a systematically designed scheme that allows execution of filtering tasks continuously, with stable pressure rating and processing momentum. This mechanism includes an integration of short flow channels that reassure minimized dwelling period of the melt within the system. The screen modification procedure is carried out without product quality alteration.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The SFXmagnus Filtration System provides a high economic efficiency that guarantees a very short melt dwell time. It has user-friendly screen changes and small size for fast and easy installation. This fully-automated product ensures consistency of melt pressure, temperature, viscosity and throughput and at the same time allows melt purity and quality.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

Melt Pressure Transducer with Integrated Amplifier The DAI Series offers – in addition to maximum reliability – improved user friendliness in the form of an Auto-Zero Function for local or remote configuration. These models offer mA and mV output signals for further processing. The popular and most commonly used 2-wire and 4-20mA configuration provide unequalled interference in critical environments.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

Melt Pressure Transducer with standardized output signal The DA Series melt pressure transducers are characterized by their high quality of workmanship and outstanding performance and are used in the plastic manufacturing and processing industries throughout the world. Their absolute reproducibility and stable measuring values contribute to our measurement accuracies. Application areas up to 300°C (572 °F) Pressure ranges from 0-50 and 0-2.000bar (0-725 and 29,000 psi) Liquid filled measuring system Maximum reliability through new membrane technology Standard G-coating to counteract adhesive materials 100% market compatible Mercury free version available at no additional surcharge

Request for a quoteResults for

Melting - Import exportNumber of results

32 ProductsCountries

Company type

Category

- Gear pumps (7)

- Silk-screen printing (5)

- Sensors (4)

- Glues, adhesives and applicators (3)

- Filters, liquid (3)

- Filtering equipment and supplies (1)

- Electrical & Electronic Components (1)

- Glues, natural (1)

- Natural fertilizers (1)

- Pipe and tube fittings - ferrous metal (1)

- Silicones (1)

- Smelting furnaces (1)

- Testing of products and materials (1)