- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixer

Results for

Mixer - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

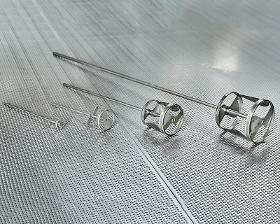

Now also available from stock: High-quality"½" standard dosing needles, as well as conical and conical black dosing needles for UV applications. In addition to the existing range of mixers and super precision needles, preeflow now also offers"½" dosing needles in various designs. The quality makes the difference: This applies to the dosing systems as well as to the required consumables such as needles and mixers. The years of experience of ViscoTec and the needle manufacturer led to the use and production of premium dosing needles. The processing and design of the dosing needles and the mixer optimizes the application and dosing accuracy of the dispenser. The high-quality needles reduce material losses and improve production performance better than comparable competing models through fast, uncomplicated changeovers and high-precision outputs.

Request for a quote

RCP RANSTADT GMBH

Germany

We not only fill the materials provided by our customers. We also have modern equipment and extensive know-how to manufacture your fillings for you according to your formulae. For this purpose, a variety of powder mixers for manufacturing the following products is available: Dietary supplements Powdered drinks Bath salts / bath pearls Detergents and cleaning products In addition, we have several liquid mixers, which can be used, for example, for Alcohol / water-based solutions Food pastes and gels Detergents and cleaning products For the manufacturing of creams, emulsions and lotions for high-quality cosmetics, we work together with specialist partners.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

With our special mixers, mixtures can be homogeneously stirred with less air in a short time.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: EM 40 Manufacturer: Ekato Description: Mixers

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: ZA 20 Manufacturer: GEA Westfalia Separator Description: Mixers

Request for a quote

WESTMARK GMBH

Germany

• from tinplated cast steel • with 4-wing knife and mincing plate hole ø 4,5 mm • with protection element from plastics for the work-top

Request for a quote

ELKON GMBH

Germany

ELKON pan mixers are preferred all over the world due to their easy and cost-effective maintenance, simple operation and batching performance. From 0,25 m³ to 3 m³ vibrated concrete per batch capacity pan mixers are available in ELKON product range. Advanced Features of ELKON Pan Mixers High batching performance Easy operation and maintenance High homogeneity even with short mixing time Highly wear-resistant mixer wear parts Easy maintenance due to wide maintenance gates and bolted type replaceable linings Low maintenance cost

Request for a quote

ELKON GMBH

Germany

ELKON planetary mixers are designed to perform high mixing performance even for the challenging applications and mostly preferred for producing precast concrete products such as low or zero slump precast concrete, fiber reinforced concrete, self-compacting concrete, etc. They provide the highest homogeneous mixture even in shorter mixing time as the mixer turret is rotating around the mixer center point and in the meantime mixing stars connected to this turret are circumvolving. Advanced Features of ELKON Planetary Mixers High mixing performance even for challenging concrete applications High mixture homogeneity in shorter mixing time High wear-resistant mixer wearing parts Easy maintenance due to wide maintenance gates and bolted type replaceable linings Italian gearbox (COBRA) Low maintenance cost

Request for a quote

ELKON GMBH

Germany

ELKON twin shaft mixers, which successfully produce concrete for various projects all around the world, has been manufacturing in ELKON’s technological factories for long time. ELKON is capable of producing 500 twin shaft mixers per shift annually thanks to its fully automated robotic welding lines. Advanced Features of ELKON Twin Shaft Mixers - Longer lifetime with robust mixer body manufactured by fully automatic welding robots - Able to produce of all kinds of concrete (Ready-mixed concrete, precast concrete, roller-compacted concrete-RCC, heavy concrete, etc.) - High homogeneity even in shorter mixing times - Highly wear-resistant, durable wearing parts - Easy maintenance due to wide maintenance gates and bolted type replaceable linings - Heavy duty gearbox (Brevini or Bonfiglioli from Italy) - Automatic lubrication system (Lincoln - Germany) - Universal compatibility to existing concrete plants with compact design

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Hydraulic mixer Ferrum DM farm loader / wheel loader requires 3rd control circuit Recommended for the models: Wheel loader Ferrum DM312 x4 Ferrum DM416 x4 V2 Ferrum DM522 x4 Ferrum DM430 x4 DLZ Ferrum DM625 x4 Ferrum DM732 x4 Court loader: Courtyard loader FIRST 12 Courtyard loader FIRST 16

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Mixer bucket for FERRUM wheel loader , here approx. 0.8m³ with a width of 1.80 m Without teeth for filling for direct absorption of sand / cement, gravel and the like Other dimensions if necessary on request (possibly also others Price) On request for almost all FERRUM models Recommended for the models: Wheel loader Ferrum DM308 x4 V2 Ferrum DM312 x4 Ferrum DM416 x4 V2 Ferrum DM522 x4 Ferrum DM430 x4 DLZ Ferrum DM625 x4 Ferrum DM732 x4 Court loader: Courtyard loader FIRST 12 Courtyard loader FIRST 16

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

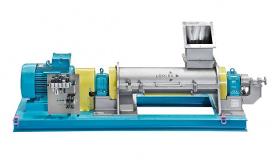

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances. The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The product is moved through the mixing chamber in a plug-flow manner. The retention time is extremely short compared with a continuous ploughshare mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. Liquid components are introduced directly into the product ring layer – either via tangentially placed liquid pipes through the drum wall or via a hollow mixing shaft with specially perforated tools. However, moistening of the mixer wall and shaft is largely prevented. The liquid distribution is similar to a nozzle but avoiding any risk of clogging or disturbance of the spray.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels on the mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products .

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These shaft made by stainless steel ,which were machining by the milling machine.Applied to specific mechanical parts.

Request for a quote

RHEIN-CHEMOTECHNIK GMBH

Germany

Heavy-duty maintenance oil for mixers, concrete trucks, moulds and machines. Excellent adhesion on dry and wet metal surfaces, prevents concrete stains, facilitates fast and easy cleaning, removes existing concrete stains when regularly used, effective rust prevention.

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

The modern mixer tap is uniformly integrated into the caravan interior - so everything stays in place even when en route.

Request for a quote

ELKON GMBH

Germany

The cement stored in the cement silos can be quickly discharged to the cement trailers (bulk carrier) by means of ELKON telescopic cement loading bellow. This system has a special structure with support legs allowing the bulk carrier parking under the discharge point and is equipped with a suitable bellow for feeding the material. ELKON telescopic cement loading bellow is equipped with level indicator to stop loading and lift up the bellow when it is in contact with the cement (material filling process is finalized). The bellow is also equipped with fan filter system to prevent powder during the material filling process. The system includes a control panel as well.

Request for a quote

ELKON GMBH

Germany

ELKON Bag Cement Feeding System consists of cement feeding bunker, intermediary cement feeding screw and control panel. The operator puts the cement bag into the cement feeding hopper and tears it by means of the cutters on the hopper. Then the cement is transferred to the cement silo by cement screw. This system can be used to feed 1 unit of cement silos as well as 2 units of silo by using distribution valve.

Request for a quote

ELKON GMBH

Germany

Cement material supplied with big bags or bags can be transferred into cement silos by means of ELKON Big Bag/Bag Pneumatic Cement Feeding System. ELKON Big Bag/Bag Pneumatic Cement Feeding System consists of cement feeding hopper, intermediary feeding screw, pressure tank, compressor, loading crane and control panel. This feeding system, which has a capacity of 15 tons/hour, is equipped with 2 tons crane to lift the big bags and dispatch into the feeding hopper. The complete set of ELKON Big Bag/Bag Pneumatic Cement Feeding System fits into 1 unit 40’OT container and thus it can be easily transported to overseas countries.

Request for a quote

ELKON GMBH

Germany

ELKON horizontal cement silos are preferred in cases where the silo location is planned to be changed frequently or in projects with height restrictions. In horizontal cement silos designed by experienced engineers of ELKON, materials with similar properties such as cement, lime, fly ash, sand etc. can be stored. Horizontal cement silos are used by placing them on the ground without the need for any foundation and ground connection, and when they need to be transported, they can be loaded and transported on the truck without the need for a crane in a very short time by means of adjustable telescopic legs. 40 and 70 ton capacity models are used both for storage and dosing. These silos with heavy-duty structures have been designed for both sea and land transportation. With axle and tyres which are presented optionally, the silo can be easily towed to the desired location on its own structure.

Request for a quote

ELKON GMBH

Germany

ELKON Cement silos are precisely manufactured by the fully automatic welding robots in production molds in ELKON-3 factory which is dedicated only for the production of cement silos. For easy and efficient transportation, ELKON provides a wide range of bolted type cement silos with the capacity of 50, 75, 100, 150, 300 and 500 tons.

Request for a quote

ELKON GMBH

Germany

ELKON Concrete Recycling Plant consists of a concrete discharge bin equipped with a shower system for washing waste concrete, a recycling unit separating coarse aggregates from the mixture and a pool where waste water discharges into. There is also an agitator which prevents the cement particles from sinking in the pool where the recycled water is stored. The pool where waste water is stored can be made from concrete underground or optionally 20 m³ capacity on ground water tank can be supplied. Thus the system can be installed on the ground level without any underground foundation. With optionally presented mobile concrete pump washing station, truck mixer and mobile concrete pump can be washed at the same time in ELKON Concrete Recycling Plant.

Request for a quote

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

ELKON GMBH

Germany

Being produced in ELKON’s latest tech production facilities, mobile continuous mixing plants (pugmills) can be easily transported via axle and tyres installed on the main unit. Thanks to its superior mobile design, these plants are installed on a flat concrete surface without foundation requirement and can be relocated easily so that the user doesn’t have to travel long distances for material transportation. These mobile pugmill plants are mainly used for for subbase (stabilization) material with / without cement production and RCC concrete for dam or road pavement projects. Mobile continuous mixing plants, also known as WOLF in ELKON’s product range, are equipped with 5000/2500 l. ELKON continuous twinshaft mixer. All materials are mixed passing through ELKON C200 mixer continuously according to the recipe and flow speed.

Request for a quoteResults for

Mixer - Import exportNumber of results

197 ProductsCountries

Category

- Concrete mixers (41)

- Chemical and pharmaceutical industry - machinery and equipment (31)

- Mixers and grinders for the food processing industry (24)

- Paint mixers and grinding machines (21)

- Chemical industry - machinery and equipment (7)

- Plastics - machines and material for industry (5)

- Mixers (3)

- Construction machinery (3)

- Biomedical equipment (2)

- Mechanical engineering - custom work (2)

- Tools, pneumatic (2)

- Cement-making - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Food industry - machinery and equipment (1)

- Laboratory equipment and instruments (1)

- Food Processing (1)

- Pharmaceutical industry - machinery and equipment (1)

- Building materials, manufacture - machinery and equipment (1)

- Chemistry - laboratory products (1)

- Concrete products and conglomerates (1)