- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laminates

Results for

Laminates - Import export

TRIGGER

Germany

We provide you with laminating services for formats up to DIN-A3. We use laminating pouches with a minimal thickness of 2 x 175 microns in our Berlin copy shop. This means you receive an especially thick, sturdy lamination, which functions as an ideal protective material. We carry laminating pouches for all the popular DIN formats.To cut specially-sized formats to their proper dimensions, the next largest standard size format is used. Resulting corners can be rounded afterwards.

Request for a quote

PETROPLAST GMBH

Germany

Laminated Film We work with laminated film characterised by its outstanding barrier properties and highly flexible sealability. Laminated film is used in the food sector, for example for packaging ready meals, fresh produce or oily food. Are you looking for the right laminated film for your product? Let us find it together. Laminated film – the facts: Laminated film for food packaging, e.g. for ready meals and fresh produce as well as oily food. Laminated film thickness: 54–67 microns, further thicknesses and laminate types on request Sealable at 140–180 °C against A-PET, C-PET, PP, PS, PE and PVC, as well as self-sealing Laminated film suitable for pasteurisation Excellent barrier properties (e.g. through PE-EVOH-PE) Available with anti-fog treatment

Request for a quote

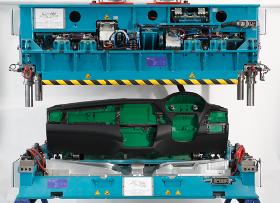

FRIMO GROUP GMBH

Germany

For sophisticated decorative materials Press laminating is mainly used to process materials that are unsuitable for vacuum processes, such as textiles, materials with and without foam backings or non-stretchable cover materials like leather or Alcantara. Processing these materials requires high quality tooling and machinery to ensure the quality of the grain, the soft touch and the color remain intact. The decorative element and the substrate are usually laminated together by being pressed between two hard instruments. Precise decor positioning and tool arrangements ensure optimal laminating conditions. Other forms of laminating include leather laminating and membrane laminating, which combines press laminating, edge folding, trimming.

Request for a quote

FRIMO GROUP GMBH

Germany

Leading the market Leather laminating is found mainly in the automotive industry. High quality vehicle interiors are characterized by a sophisticated design made of perfectly processed and adapted materials. Leather surfaces are no longer exclusively reserved for premium vehicles; they are also becoming increasingly used in high volume and mid-priced vehicle interiors. As a natural material, leather presents tough processing challenges. Variations, quality/quantity requirements and numerous project-specific parameters demand smart manufacturing solutions that can only be produced with extensive experience and in-depth technology and process expertise. FRIMO's tooling and equipment technology in leather processing leads the market. Along with leather laminating come leather back-foaming and leather scoring for hidden airbags.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for high quantities In vacuum laminating, plastic films such as TPO, TEPEO2 ® and PVC are heated and vacuumed to plastic substrate components, resulting in lamination. The adhesive applied to the substrate or decor material is activated, causing the two parts to bond. Vacuum laminating's special feature is that is can be combined with IMG (In-Mold Graining) in a single process. FRIMO offers this innovative and attractive technology with extensive market references.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

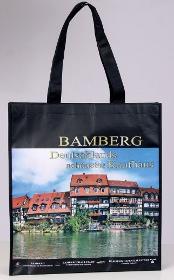

BAGOBAG GMBH

Germany

Non-Woven Bags printed. Initial print run (MOQ) of 1,000 pieces. PP Non-Woven bag with lamination - Bamberg Impression: 10.000 pieces Size: 38 x 42 x 10 cm + 3 cm (width x height x depth + fold over) Material: 80 g / m² PP Non-Woven laminated with BOPP Matte Film 30 g / m (total 110 g / m²) Printing: rotogravure engraving 5 color CMYK and white paint; the two front sides of the bag have different motifs Gravure printing cylinder: included Handles: Two carrying straps same PP Non-Woven - but uncoated, double layered - stitched on both edges of the longitudinal sides of the belt. The four ends are sewn on the inside edge of the fold over, the top of the bag body; total length 2 x 60 cm, width 2.5 cm. Work out: stitched as exclusive PP Non-Woven bags. On the edges of the side gussets a revolving braid sewn closes the edge endings. A fold laterally in the middle of side gussets, second folds middle of the bottom. Enquête PP Non-Woven bags or cotton bags. What should I take or...

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

The SC1 in blue Chemprotex™ 300 material is a single use Type 3, Type 4 & Type 5 splash contamination suit designed for use with breathing apparatus worn outside the suit or with a face mask and filter. The garment is CE certified to EN14605:2005+A1:2009, EN13982-1:2004+A1:2010, EN14126:2003, EN1073-2:2002 and EN1149-5:2008 and is intended for use in areas that are not immediately dangerous to life or health. One-piece construction Integral hood with neoprene rubber face grommet to seal around the wearer’s face mask 91cm (36”) Nylon zip fitted across the shoulders in rear of suit, flapped internally and encased in a double external housing with self adhesive tape closure Chemically protective laminated glove welded to the suit material Integral socks in the same Chemprotex™ 300 material as the suit with plain outer leg allowing the wearing of customer’s own boots. (Boots not included) Protection TYPE 3, TYPE 4 (EN 14605:2005+A1:2009, Protective clothing against liquid chemicals.

Request for a quoteResults for

Laminates - Import exportNumber of results

8 ProductsCountries

Company type